HSG Laser’s sheet metal systems combine compact, industrial-grade design with cutting-edge automation and Industry 4.0 connectivity — engineered for speed, stability, and long-term productivity.

Designed to cut mild steel, stainless steel, aluminum, brass, and copper, these machines deliver clean edges, tight tolerances, fast cycle times with minimal heat-affected zones. Ideal for job shops, OEMs, and high-volume manufacturers, HSG Laser solutions help reduce lead times, lower production costs, and improve part quality. With advanced automation, intelligent nesting software, and high-speed motion systems, these lasers provide the performance and efficiency demanded by today’s fabrication industry.

Powerful Performance

Smart Cutting Heads

Lightweight Aluminum Beam

Industry 4.0-Ready

HSG lasers are built for high-speed, high-precision cutting with low energy use and minimal maintenance — perfect for busy, high-demand shops.

Smart Features for Better Workflow

Built for Long-Term Use

Click the dropdowns below to view detailed specifications for the Sheet Metal Lasers.

Specification | Metric | Imperial |

Laser Power | 12kW – 60kW | 12000W – 60000W |

Machining Area | 12100mm x 3500mm (G12025FA) 12100mm x 2500mm (G12035FA) | 476.38in x 137.80in (G12025FA) 476.38in x 98.43in (G12035FA) |

Positioning Precision of X/Y Axis | ±0.05mm/m | ±0.00060in/ft |

Repetitive Positioning Precision of X/Y Axis | ±0.05mm | ±0.00197in |

Max Linkage Speed | Varies by model Consult Bramac for specific technical data | |

Max Linkage Acceleration | 0.5G | |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

Core Attributes | High-Power Laser Cutter for Oversized Sheet Metal Extended Bed Design: Spliced machine frame available in custom lengths Integrated Extraction System: Tailored ventilation and dust collection for cleaner operation Versatile Bevel Cutting Option: Precision angled cuts for a variety of geometries and profiles | |

Specification | Metric | Imperial |

Laser Power | 3kW – 30kW | 3000W – 30000W |

Machining Area | 3048mm x 1524mm (G3015X) 4064mm x 2040mm (G4020X) 6096mm x 2540mm (G6020X) 12500mm x 2540mm (G12025X) | 120in x 60in (G3015X) 160in x 80.3in (G4020X) 240in x 100in (G6020X) 492.1in x 100in (G12025X) |

Positioning Precision of X/Y Axis | ±0.03mm/m | ±0.00036 in/ft. |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.001 inches |

Max Linkage Speed | 140m/min | 459 ft/min |

Max Linkage Acceleration | 1.5G | |

Max Loading Weight of Platform(s) Varies by model and wattage; consult Bramac for specific technical data | 885kg – 1400kg (G3015X) 1570kg – 2500kg (G4020X) 2950kg – 4800kg (G6025X) 9500kg – 12000kg (G12025X) | 1951lb – 3086lb (G3015X) 3461lb – 5512lb (G4020X) 6503lb – 10582lb (G6025X) 20944lb – 26455lb (G12025X) |

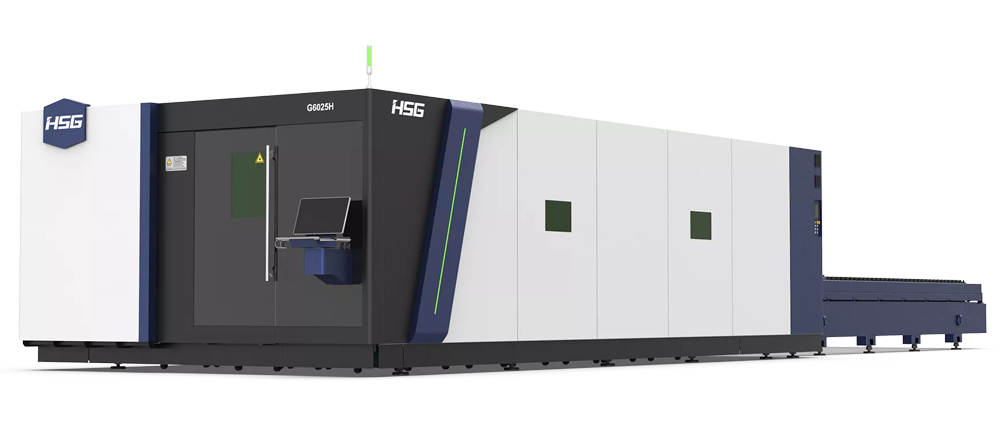

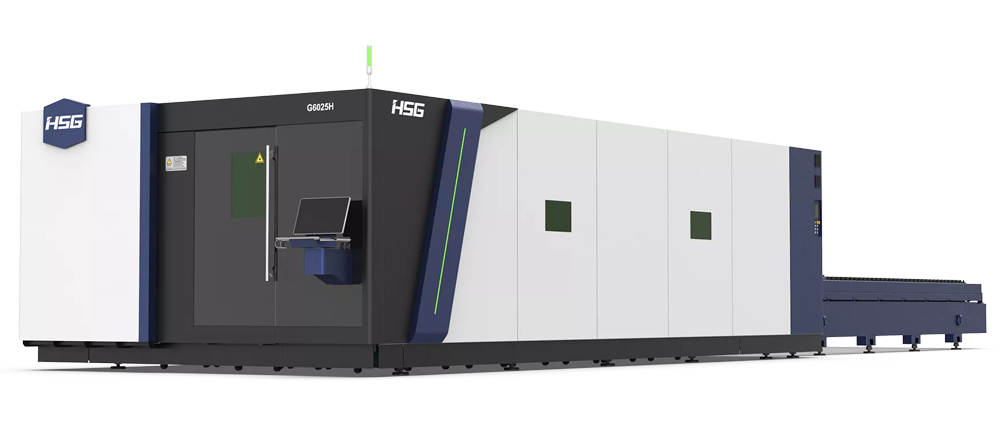

Core Attributes | Dual Pallet Exchange Laser Cutter: Boosts productivity with continuous cutting and loading/unloading Upgraded Bus Control System: Delivers faster response times and enhanced precision Enclosed Design for Safety & Sustainability: Fully protected cutting area with environmentally conscious features | |

Specification | Metric | Imperial |

Laser Power | 3kW – 30kW | 3000W – 30000W |

Machining Area | 3048mm x 1524mm (G3015H) 4064mm x 2040mm (G4020H) 6096mm x 2540mm (G6020H) 12500mm x 2540mm (G12025H) | 120in x 60in (G3015H) 160in x 80.3in (G4020H) 240in x 100in (G6020H) 492.1in x 100in (G12025H) |

Positioning Precision of X/Y Axis | ±0.03mm/m | ±0.00036 in/ft. |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.001 inches |

Max Linkage Speed | 200m/min | 656 ft/min |

Max Linkage Acceleration | 4G (G3015H) 2.8G (All other models) | |

Max Loading Weight of Platform(s) Varies by model and wattage; consult Bramac for specific technical data | 885kg – 1400kg (G3015H) 1570kg – 3800kg (G4020H) 6300kg – 9400kg (G6025H) 9500kg – 14500kg (G12025H) | 1951lb – 3086lb (G3015H) 3461lb – 8378lb (G4020H) 13889lb – 20725lb (G6025H) 20944lb – 31967lb (G12025H) |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

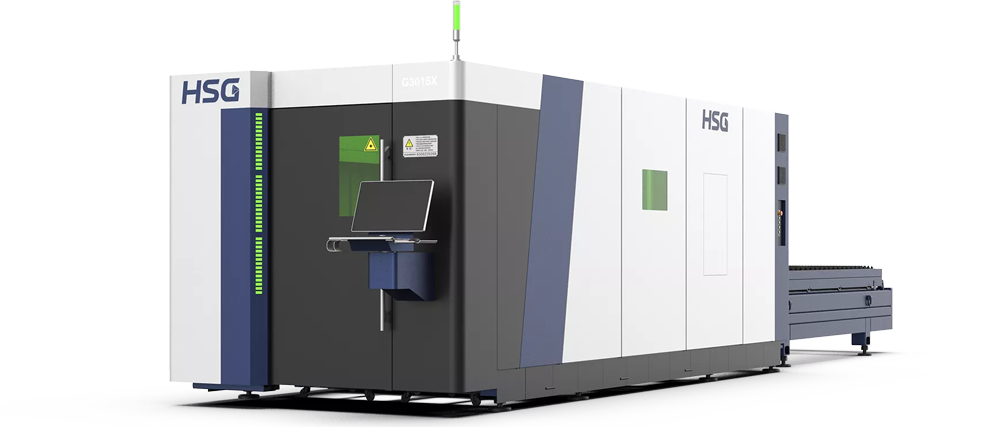

Core Attributes | Advanced Fiber Laser Cutting System: Built for high-speed, high-precision performance Smart Bus Control: Ensures responsive, stable, and streamlined machine operation Thermal Protection Design: Engineered to resist heat without compromising material or machine integrity Reinforced Matrix Bed Structure: Enhanced rigidity for superior stability and long-term cutting accuracy | |

Specification | Metric | Imperial |

Laser Power | 6kW – 60kW | 6000W – 60000W |

Machining Area | 4.064mm x 2032mm | 160in x 80in |

Positioning Precision of X/Y Axis | ±0.01mm/m | ±0.0001in |

Repetitive Positioning Precision of X/Y Axis | ±0.00762 mm | ±0.0003 inches |

Max Linkage Speed | 300m/min | 984 ft/min |

Max Linkage Acceleration | 6G | |

Max Loading Weight of Platform(s) | 5000kg | 11023lb |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

Core Attributes | 6th-Gen Linear Motor Fiber Laser Cutter: Flagship model featuring full linear drive technology for next-level performance Ultra-Fast Motion System: Delivers smooth, high-speed dynamics for precision cutting with a premium finish Hydraulic Lift Dual Pallet Exchanger: Efficient material handling to keep production moving Heavy-Duty Bed for High-Power Output: Engineered for stability and durability under intense cutting loads | |

Specification | Metric | Imperial |

Laser Power | 1.5kW – 12kW | 1500W – 12000W |

Machining Area | 3048mm x 1524mm (1.5-6kW) 3000mm x 1500mm (12kW) | 120in x 60in (1.5 – 6kW) 118.11in x 59.06in (12kW) |

Positioning Precision of X/Y Axis | ±0.03mm/m | ±0.00036 in/ft. |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.00118 inches |

Max Linkage Speed | 120m/min | 394 ft/min |

Max Linkage Acceleration | 1.5G | |

Max Loading Weight of Platform(s) | 200kg | 441lb |

Core Attributes | Precision Laser Cutting Solution: Designed for detailed, high-accuracy applications Enclosed Build with Sliding Platform: Sealed frame and single push-pull table for safety and space efficiency Autofocus Cutting Head: Automatically adjusts focal length for clean, consistent cuts across materials Versatile Bus Control System: Supports a range of intelligent functions for streamlined operation and control | |

A: HSG fiber lasers can cut a wide range of metals including carbon steel, stainless steel, aluminum, brass, and copper. Higher wattage models can also handle thicker gauges and specialized materials with excellent precision.

A: Depending on the power level, HSG lasers can cut:

Available models range from 1kW to 30kW+, giving flexibility based on production needs.

A: HSG delivers comparable cutting performance and automation capabilities at a significantly lower investment cost. It’s built for fast ROI, user-friendly operation, and scalable automation — ideal for job shops, contract manufacturers, and OEMs.

A: HSG offers a full suite of automation including:

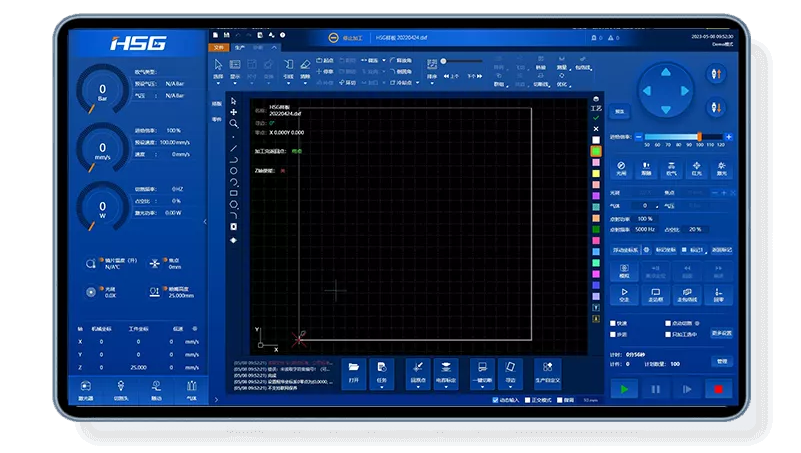

A: Yes — operator training is included with every HSG installation. Most operators are fully functional within 1–3 days, thanks to intuitive software and touchscreen controls.

A: HSG has an expanding North American support network offering:

HSG also partners with trusted distributors to ensure a responsive service.

A: It depends on your typical material thickness and throughput. Bramac Machinery, Inc. offers guidance to help choose the best machine for your workload.

A: Yes — HSG’s proprietary software is built for fast setup and minimal learning curve. It supports:

Operators can navigate the system quickly with touchscreen control and English-language interfaces.

A: Absolutely. HSG machines are designed with modular upgrades in mind — whether you want to add automation, increase power, or add pipe cutting capability later on.

A: Lead times vary by model and configuration, but HSG typically offers faster delivery than many Western competitors. Standard flatbed machines can often ship within 6–12 weeks, depending on stock and customization.