- MicroPlus

- LaserPlus

- Traveling Steady

- Auto-Stick

- IView

- Wheel Probe

- Wheel Spindle

- Wheel Changer

- RoboMate Loader

Australian Numerical Controls and Automation (ANCA) is a market leader of high quality tool and cutter grinders. As well as tool and cutter grinders for the metal and woodworking sectors ANCA offers specialist machines for various industries.

For more information visit: ANCA Machines Website

Or contact us directly.

ANCA machines | FX Linear | MX Linear | TX Linear | EDGe | SBG | CPX Linear | FCP4 |

ANCA Integrated Manufacturing System | AIMS brochure |

Accessories | MicroPlus | LaserPlus | Auto-Stick |

Software | Management Suite | ToolRoom | ToolDraft | CIMulator 3D |

Photo © ANCA, used by permission

Rush Machinery provides top quality products and service that help our customers grind better. Rush machines are used for: Truing and dressing diamond wheels; Cutting off carbide/HSS rods and tools; Cutting, prepointing, and chamfering carbide/HSS rods; Chamfering carbide/HSS rods; Balancing wheels and tools: Grinding PCD tools; Filtering grinding oil; and Sharpening drills and tools.

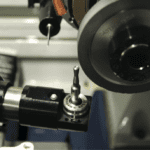

Wheel Truing and Dressing Machines

Our wheel dressers are designed for truing and dressing flats, angles, and radii on CBN and diamond single wheels as well as multiple wheel packs. The machines offer quick-change spindle options with available adapters to meet the needs of any CNC or non-CNC grinding machine. The machines also have two pairs of angular contact bearings for rotary table pivots. Rush Wheel Dressers are accurate, cost-effective, and easy to operate. Paired with our wheel truing and dressing machines, our customized RushVision software simplifies high-tolerance truing and dressing. It is easy to set up and can inspect wheel diameter, position, and width during and after dressing.

Cut-Off Machines

Rush Machinery is a leading manufacturer of CNC cut-off machinery for cutting carbide, hardened steel, and HSS rod and tool ends. Our unique cut-off machines offer various features, such as automatic loaders, automatic CNC controls, and 2-axis servo motors.

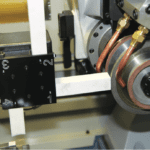

CH-CM0406 CNC Cut-Prepoint-Chamfer Machine

The CH-CM0406 CNC Cut-Prepoint-Chamfer Machine can save you time and money because it combines three processes cutting, prepointing, and chamfering into one machine. This computer-controlled machine requires minimal human intervention, producing quality results. This machine is a three-in-one solution that offers a better alternative to owning and running separate machines for cutting, prepointing, and chamfering metal cutting tools. If the blank carbide rods are prepped ahead of time, the CH-CM0406 CNC Cut-Prepoint-Chamfer Machine can significantly boost production and reduce cycle time on finished tool grinding.

PCD Tool Grinders

The Polycrystalline Tool Grinders allow for economical manufacturing and regrinding of: PCD, CVD, PCBN, Carbide, and HSS tools. These machines grind angles and radii on standard and special turning and milling inserts, boring tools, milling cutters, grooving tools, reamers, and other special tools. The rigid construction with a 3-HP variable speed grinding spindle provides for vibration-free grinding and fast stock removal.

Bramac Machinery is the exclusive representative for Rush Machinery products for California, Arizona and Nevada.

For more information visit: Rush Machinery Website

Or contact us directly.

APhotos © Rush Machinery, used by permission

Toolroom Solutions offers high quality accessories for Tool & Cutter Grinders. Products include:

- World-class Toolgal grinding wheels

- GDS wheel adapters (made in Germany, meet or exceed all OEM specs)

- Wheel balancing machines

- Market leading workholding from GDS

- Replacement parts & tooling for leading Tool & Cutter Grinder brands

- Major machine service, repair and upgrades

For more information visit: Toolroom Solutions Website

Or contact us directly.

Photos © Toolroom Solutions, used by permission

Ebbco Inc. is a full service design and build manufacturer of metalworking filtration since 1983. Ebbco has developed filtration systems for multiple industries such as EDM, Waterjet, Precision Machining, Coolant Clarification, Grinding and Stone working.

For more information visit: Ebbco Filtration Website

Or contact us directly.

Photos © Ebbco, used by permission.

- EDM Fluids

- Industrial Oils

- Rust Preventatives

- Cleaners

- Straight Oils

- Water-Miscibles

ML LUBRICATION was founded in 1981 in the center of the industrial city of Schweinfurt, Germany, located in the heartland of the ball bearing industry.

Today ML LUBRICATION is a truly global player in the industrial lubricant market, with production facilities crossing four major continents, in eight different countries, a global distribution network. Their North American headquarters is based in Atlanta, GA. With the newly established state of the art technical service center, ML Lubrication USA, INC is in a primary position to supply high-quality products and services across the entire US.

Water Miscible Coolants

Where cooling efficiency and tribology requirements overlap, ML Lubrication offers a wide selection of products for the metal removal and deformation processes. Starting from oil free synthetic coolants extending to micro and macro emulsification technology systems.

Straight oils

The straight oil product line encompasses low viscosity high speed precision surface finish fluids to the arduous extreme pressure anti welding metal deformation fluids. With market proven leading technology ML Lubrication can help improve surface finishing by reducing abrasive and adhesive wear helping reduce Ra and Rz values.

Cleaners

Organic residues can often be troublesome to remove either from modular process or after heat treatment. Solvent-based or aqueous-based systems, with our liquid solutions philosophy, ML Lubrication offers a vast portfolio of products to meet the most demanding industrial cleaning requirements.

Rust Preventatives

Transportation, indoor and outdoor storage of metallic components can be treated with the pioneering film forming technology provided by ML Lubrication. Ranging from thin dry films to thick waxy undulating coverings, applied via, spray, immersion or brushing. Preventing the metallic oxide surface layer being exposed to the environment.

Industrial oils

Keeping a running system performing under optimum conditions requires the use of multiple lubricants ranging from hydraulic oils designed for gear, piston, vane, and hybrid pumps. Gear oil selections with varying viscosities. Way lubes for both horizontal and vertical slideways. To the light thermal and oxidatively stable spindle oils. Whatever your requirements ML has you covered.

EDM Fluids

Complexed geometric structures can often lead to time-consuming and complicated setups for traditional CNC operations, which has led to a global increase in EDM manufacturing. The extensive product line of EDM fluids from ML Lubrication covers conventional EDM operations such as Sinker, Plunge, and Ram, along with wire EDM, micro EDM, fast hole drilling, plus small hole drilling. Our technology will be able to assist in extending electrode lifetimes, improved feed rates, and shorter eroding times. The EDM fluids have been formulated to achieve maximum aging stability aiming at extended service life. With low odor meeting the highest occupational health standards.

For more information visit: ML Lubrication Website

Grinding Machine Metal Working Fluids Flyer

CNC Swiss-Type Turning Center Oil Flyer

Or contact us directly.

Photos © ML Lubrication, used by permission.

BUMOTEC Swiss built high precision mill/turn machines provide multi tasking solutions for complete part manufacturing

s191neo Single Station Multi-Tasking solution

Working from bar or blanks, bar capacity: 1.65", 1.97" & 2.56"

Linear motors and drives, Up to 7 axis and 3 spindles

Tool magazine 30 (60 or 90 optional) HSK-E40 or HSK-T40

5 Axis simultaneous machining

30,000 rpm (40,000 optional)

s181 2 Station Multi-Tasking solution

2 machining stations

Linear motors and drives

Station 1

30,000 rpm (40,000 rpm option)

5 axis simultaneous machining

Tool magazine 30/60/90, HSK40-A

Station 2

8,000 rpm (28,000 rpm option)

HSK32-C

For more information on the s191 and s181: Bumotec Brochure

For more information visit: Bumotec website

Or contact us directly.

Photos © Starrag - Bumotec, used by permission

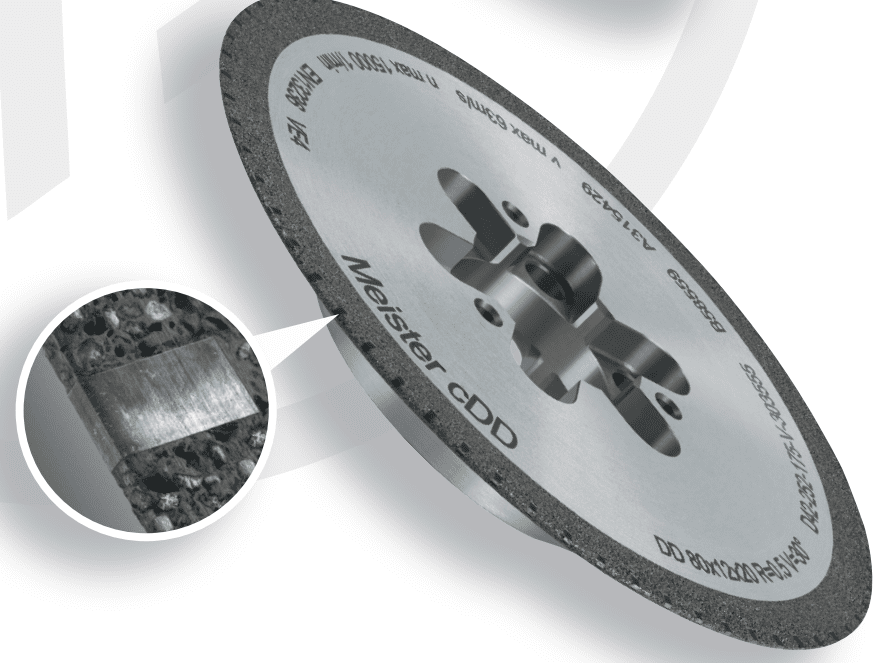

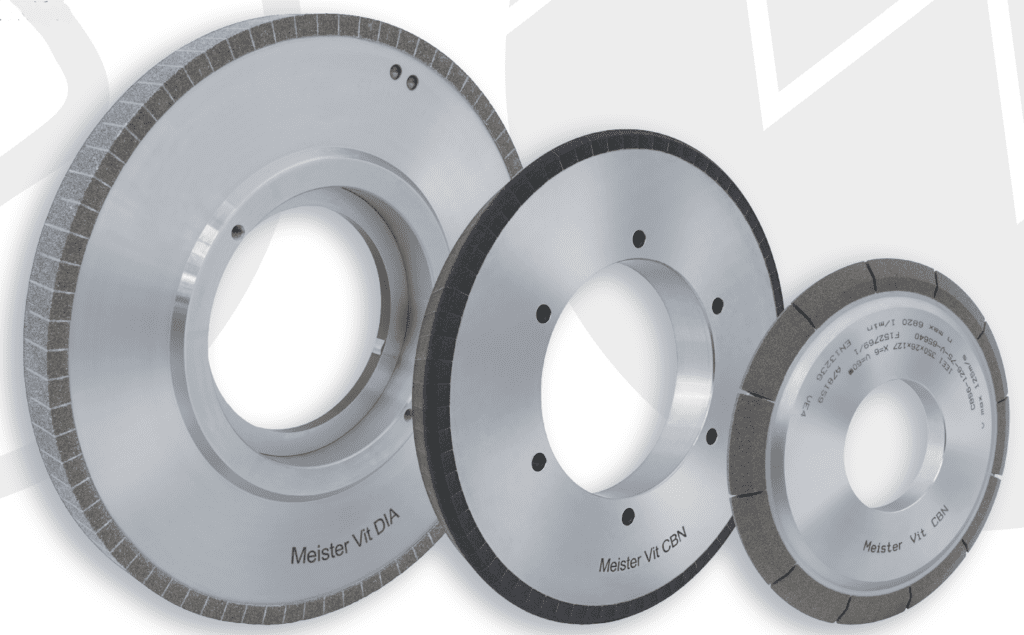

External Grinding Wheels

Meister offers ceramic and hybrid bonded CBN and diamond grinding tools for applications with the highest demands. The tools achieve excellent surface qualities and component geometries for profile plunge grinding, peel-grinding, centerless and general external cylindrical and non-cylindrical grinding.

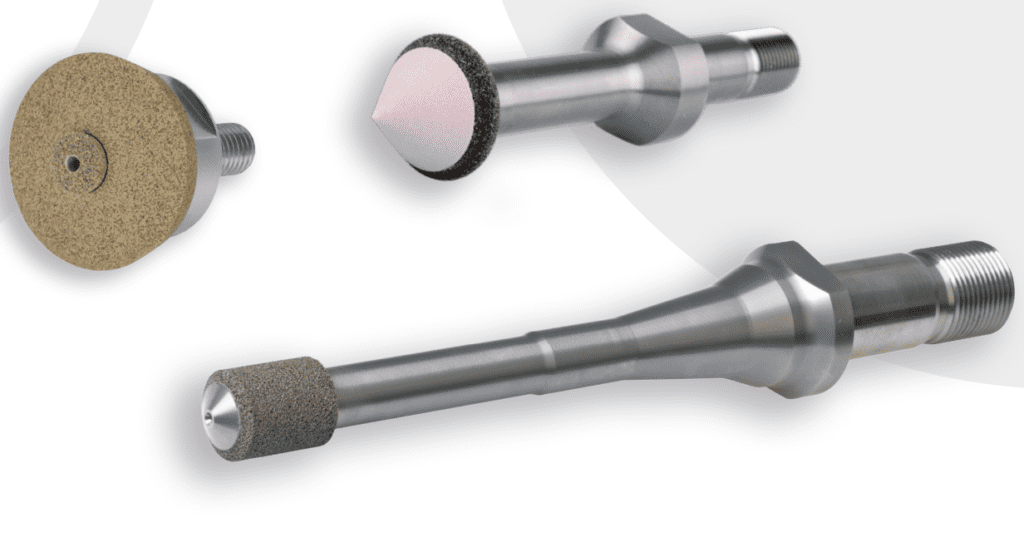

Internal Grinding Wheels

Meister offers internal grinding tools for finishing of precision components with the highest tolerance requirements. Ceramic and hybrid bonded CBN, diamond and conventional grinding wheels are used. These include grinding fuel injection nozzles, pump & gear parts, roller bearings, gears, valves and many more.

Dressing Tools

Meister is a leader in the technological development of porous dressing tools. The focus is on highly porous free-cutting structures, combined with a corresponding wear resistance, which significantly improves the workpiece quality and process stability. Depending on the requirements, the bonding systems can be ceramic (vDD) or preferably hybrid technology (hDD).

For more information visit: Meister Abrasives Website

Or contact us directly.

Brochures: | Product Range Flyer | Hybrid Rotary Dressing Tools | Hybrid Stationary Dressing Tools |

![]() | Dressing Video |

| Dressing Video |

Photos © Meister Abrasives, used by permission.

- Laser

- Scribe

- Impact

- Rolling

- Presses

- Hot

- Dot Peen

- Electrolytic

Automator is a world wide leader in industrial marking equipment and solutions. Technologies include laser, dot peen, impact, scribe, rolling, presses, hot and electrolytic. This comprehensive range of marking systems caters to a wide range of industries and materials.

For more information visit: Automator Marking Website

Or contact us directly.

Customer references | USA Customers |

Products | General Brochure | Laser |

Photos © Automator, used by permission.

World-Class Compressed Air and Nitrogen Systems

PSB Piston-Style Air Compressors 5-30 HP

PSB Piston compressors are incredibly reliable units that range from 5-30 HP. They are built to last in manufacturing environments that require smaller amounts of HP at a constant load.

RK Variable Speed Drive Compressors – 5-10 HP

The RK VSD 5-10 series air compressors are rotary screw type with a horsepower range of 5, 7.5, and 10. These units are designed for energy efficiency and longevity. Available in tank mounted and integrated dryer configurations.

RK Variable Speed Drive Compressors 15-75 HP

The RK VSD 15-75 series air compressors are rotary screw type units in the mid-horsepower range. They are designed for energy efficiency and longevity.

RKHD Variable Speed Rotary Screw Compressors 50-420 HP

The RKHD is a series of oil-flooded, rotary screw air compressors particularly designed for generating industrial use compressed air.

In case of non-continuous needs and several daily fluctuations of air demand, the RKHD–VSD is the most suitable solution. Low rotational ensures a long life and high efficiency of the compressor. The variable speed version is equipped with a Inverter Duty Motor.

RDA Non-Cycling Dryers 13-550 CFM

RDA Non-Cycling dryers are an excellent way to keep moisture out of your compressed air system with a relatively low initial investment.

RDA Variable Speed Dryers 800-6000 CFM

The PneuTech RDA Variable Speed Dryer features a vertical heat exchanger that handles super-high temperatures, has a large condenser that maximizes performance, and an energy-efficient refrigeration compressor. The VSD on the compressor allows the unit to react to demands. KW consumption syncs with your compressed air dew point demand. The large touch-screen display monitors the pressure and operating temperature, calculates the heat load and adjusts the rotation speed of the compressor and fans. Also capable of remote control with the RS485 interface that comes standard. Combined with the variable speed fan drive, the RDA Variable Speed Dryers offer significant energy savings.

Nitrogen Gas Generators

On-site nitrogen generation can help you reduce costs, control purity and ensure a consistent supply of nitrogen gas (N2) when and where you need it. PneuTech offers top-quality nitrogen generators for reliable on-site gas generation, including membrane and Pressure Swing Adsorption (PSA) units. PneuTech nitrogen generators are designed to provide low operating costs, easy maintenance and long service life. With PneuTech you are guaranteed a consistent supply of nitrogen at your precise purity specifications.

For more information visit: Pneutech Website

Or contact us directly.

Photos © Pneutech, used by permission.

Tecnomagnete has been developing magnetic work holding systems for 35 years. Products include permanent-electro magnetic systems to clamp workpieces on milling, grinding, turning machines and special equipment for rail machining. Magnetic QMC systems to clamp molds for plastic injection molding machines and metal presses, and manual lifters for loads up to 2000kg.

For more information about Tecnomagnete please visit their website.

Or contact us directly.

Photos © Tecnomagnete, used by permission.

- Cabinets

- Workstation

- Shelves with drawers

- Workbenches

For over 75 years Rousseau Metals has been designing and manufacturing customizable durable and heavy-duty industrial storage and workstations in North America.

Products include:

Tool Boxes, Heavy Duty Cabinets, Workstations, Workbenches, Modular Shelving and CNC Storage Solutions.

All products are customizable and available in 20 standard colors.

Rousseau catalog: Product Line Brochure

For more information visit: Rousseau Metals Website

To build your customized Rousseau product: MyModel-r Configurator

Product Flyers: | Modular Drawer System | Toolbox System | R Cabinet | R-Go Motorized Tool Box | L Cabinet | L50 Electronic Lock system | CNC Storage Solutions | Workstation System | MULTITEK Cart | TEKZONE Workstation Hutch | Spider ® Shelving System | Freestanding Station |

Videos: | Why Rousseau? | The R cabinet | R2V Vertical Storage | R-Go Motorized Platform | R-Go Motorized toolbox | The L cabinet | The L50 Electronic Lock | Before and After: JF Kustoms Garage |

Photos © Rousseau Metals, used by permission.