Spinner CNC’s Turning Centers offer precision-engineered solutions for diverse machining needs, from large big bore lathes to compact submicron precision turning machines, backed by over 75 years of turning technology expertise.

CNC turning centers are advanced machine tools that automate the turning process, enhancing precision and efficiency in manufacturing. They are essential in producing cylindrical parts across various industries, including automotive, aerospace, and medical devices. The integration of computer numerical control allows for complex geometries and high repeatability, making these machines vital for modern production environments.

Spinner CNC’s turning centers are designed with optimized castings and sliding guides, ensuring maximum rigidity and damping. They feature a true 30° inclined bed for effective chip management and high-precision motor spindles with active temperature control. With capabilities like up to 4.3″ bore and 62.2″ turning length, live tool turrets for rapid tool changes, and plug-and-play automation readiness, these machines are engineered for high performance.

Choosing Spinner CNC’s turning centers means investing in machines that enhance productivity and profitability. Their robust design ensures durability, while advanced features like live tool turrets and automation compatibility reduce cycle times and labor costs. This combination leads to higher precision in parts production, meeting the stringent demands of today’s manufacturing sectors.

Click the dropdowns below to view detailed specifications for the CNC Turning Centers.

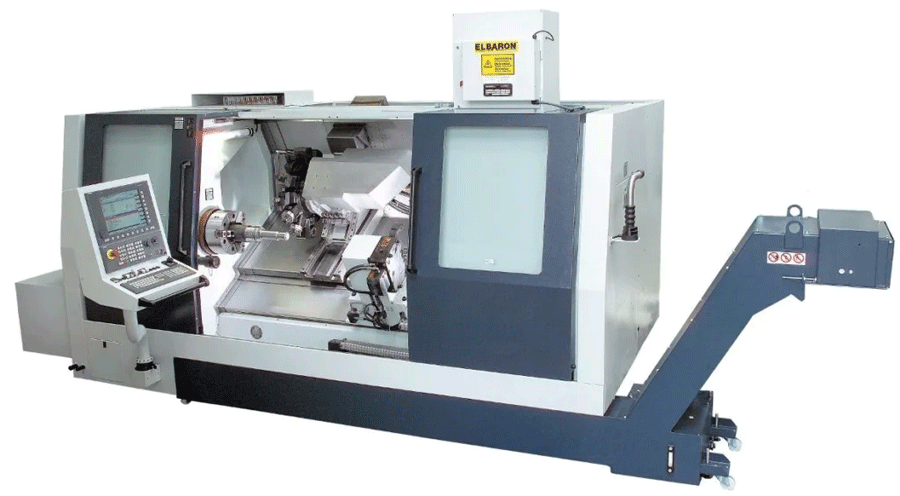

| Big Bore Long (TC800L) | |

|---|---|

| Max Turning Diameter | Not specified |

| Max Turning Length | Up to 62.2 inches (1580 mm) |

| Spindle Bore Diameter | Up to 4.3 inches (110 mm) |

| Bed Design | True 30° inclined bed |

| Guide Type | Box way design with sliding guides |

| Spindle Type | High-precision motor spindle with active temperature control |

| Automation Compatibility | Plug-and-play automation ready |

| Big Bore (TC800) | |

|---|---|

| Max Turning Diameter | Not specified |

| Max Turning Length | Not specified |

| Spindle Bore Diameter | Up to 4.3 inches (110 mm) |

| Bed Design | True 30° inclined bed |

| Guide Type | Box way design with sliding guides |

| Spindle Type | High-precision motor spindle with active temperature control |

| Automation Compatibility | Plug-and-play automation ready |

| Large Long (TC610L) | |

|---|---|

| Max Turning Diameter | Not specified |

| Max Turning Length | Not specified |

| Spindle Bore Diameter | Not specified |

| Bed Design | True 30° inclined bed |

| Guide Type | Box way design with sliding guides |

| Spindle Type | High-precision motor spindle with active temperature control |

| Automation Compatibility | Plug-and-play automation ready |

| Mid-Sized Flexibility (TC600) | |

|---|---|

| Max Turning Diameter | Not specified |

| Max Turning Length | Not specified |

| Spindle Bore Diameter | Not specified |

| Y-Axis Capability | Yes |

| Live Tooling | Yes |

| Bed Design | True 30° inclined bed |

| Guide Type | Box way design with sliding guides |

| Spindle Type | High-precision motor spindle with active temperature control |

| Automation Compatibility | Plug-and-play automation ready |

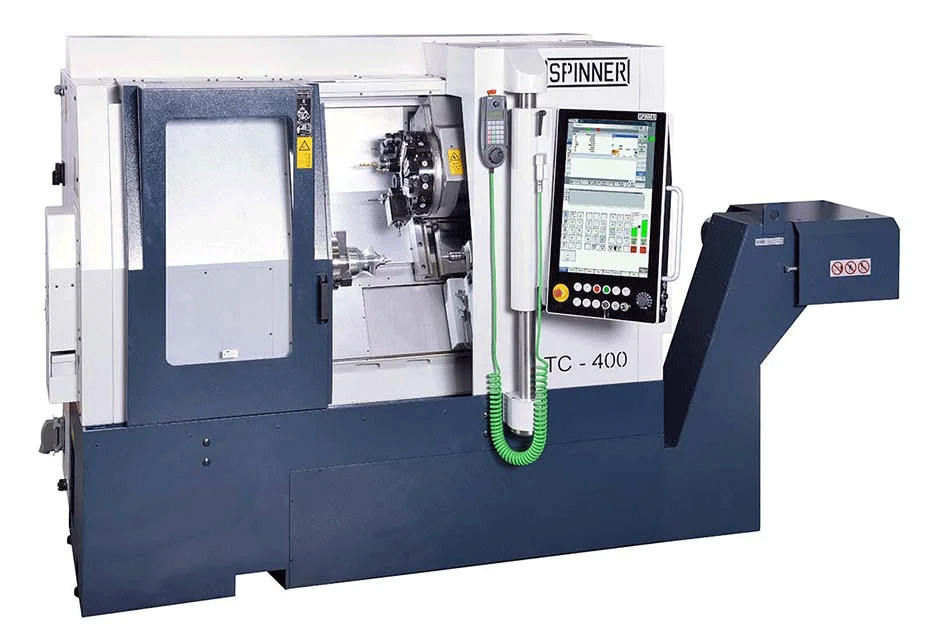

| Compact Workhorse (TC400) | |

|---|---|

| Max Turning Diameter | Not specified |

| Max Turning Length | Not specified |

| Spindle Bore Diameter | Not specified |

| Bed Design | True 30° inclined bed |

| Guide Type | Box way design with sliding guides |

| Spindle Type | High-precision motor spindle with active temperature control |

| Automation Compatibility | Plug-and-play automation ready |

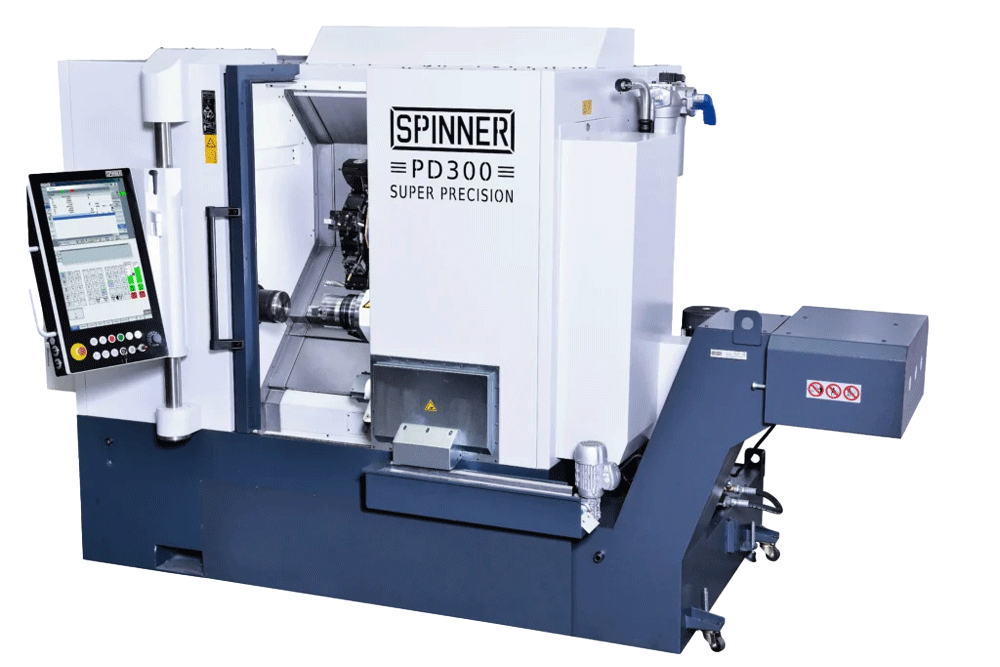

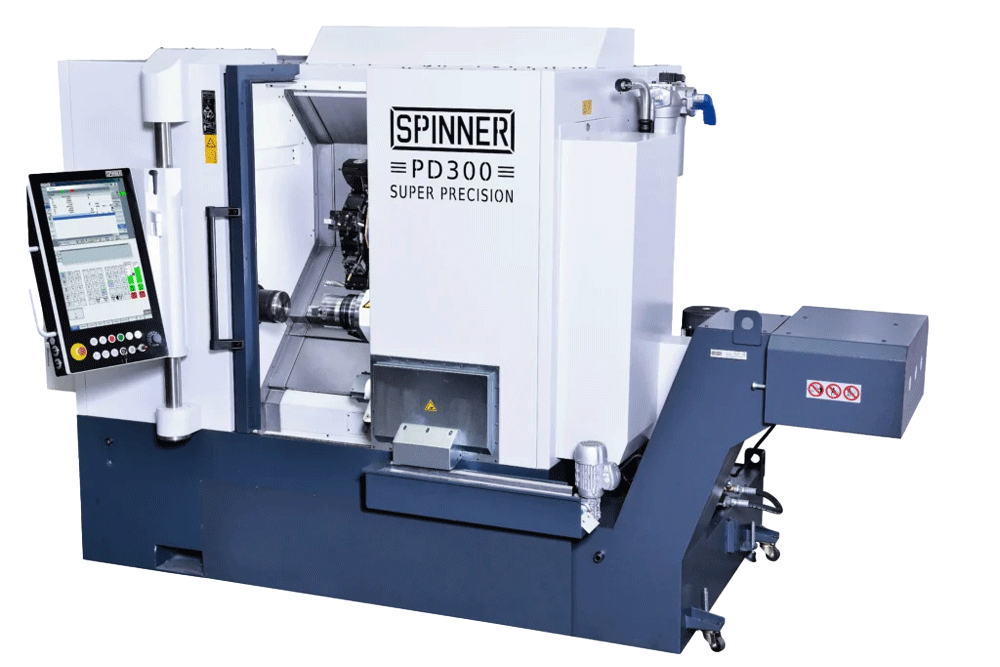

| Micron Machining (PD300) | |

|---|---|

| Max Turning Diameter | Not specified |

| Max Turning Length | Not specified |

| Spindle Bore Diameter | Not specified |

| Bed Design | True 30° inclined bed |

| Guide Type | Box way design with sliding guides |

| Spindle Type | High-precision motor spindle with active temperature control |

| Micron-Level Precision | Designed for submicron precision turning applications |

| Automation Compatibility | Plug-and-play automation ready |

A: Spinner CNC provides a range of turning centers, from large big bore lathes to compact submicron precision machines, catering to various application needs.

A:The true 30° inclined bed ensures effective chip management, enhancing machining efficiency and surface finish quality.

A: Spinner CNC’s machines offer up to 62.2″ turning length, accommodating larger workpieces.

A: Yes, the machines are designed with plug-and-play automation capabilities, facilitating seamless integration into automated production lines.

A: Industries such as automotive, aerospace, and medical devices benefit from the precision and efficiency of Spinner CNC’s turning centers.