The STX Series from Nissei delivers quick mold changes, flexible clamping, superior efficiency, advanced safety, and economical options, making it indispensable for maximizing injection molding productivity.

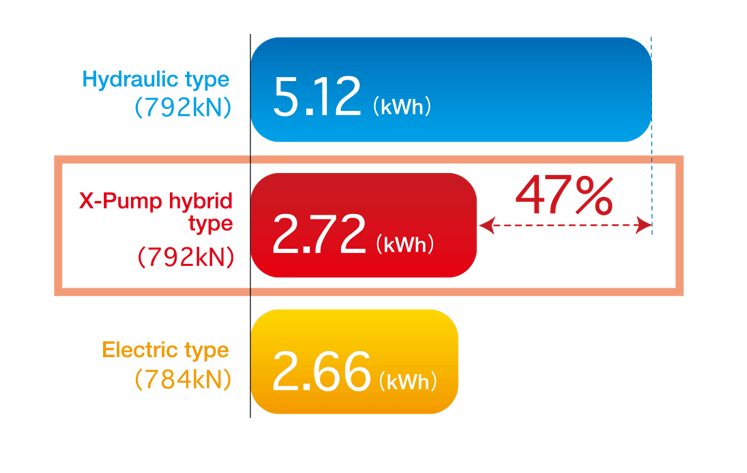

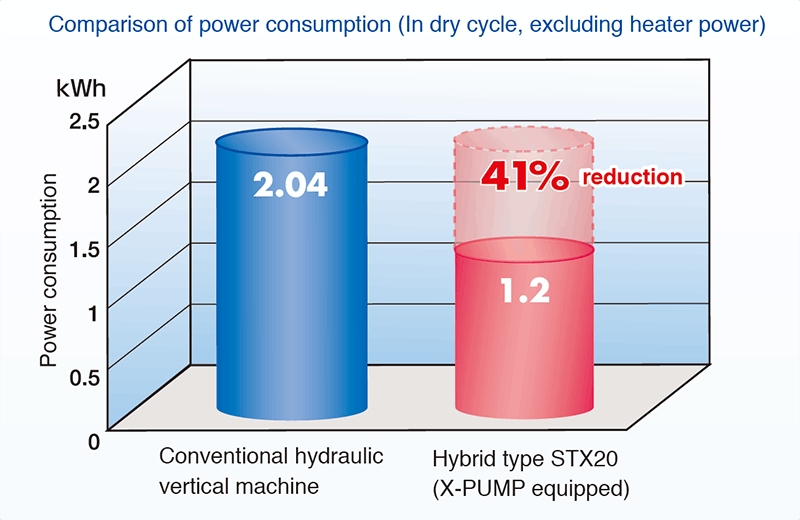

The Nissei STX Series is a compact vertical hybrid injection molding machine designed for precision and efficiency. Evolving from the ST Series, it incorporates the advanced X-Pump® System, combining hydraulic control with servomotor drive technologies. This fusion enhances injection performance and energy efficiency, making the STX Series ideal for molding high-precision automotive and electronics parts.

Key features of the STX Series include a high-response injection system with approximately half the response time of conventional machines and an injection speed 1.3 times faster. It offers stable control in ultra-low speed ranges and achieves about 40% less power consumption. The space-saving design, with floor dimensions of 860mm x 850mm for the STX10 and 900mm x 1000mm for the STX20, provides excellent layout flexibility and automation adaptability.

Choosing the STX Series ensures quick injection response, wide-ranging injection speeds, and stable control in ultra-low velocity ranges. The high-rigidity straight-hydraulic clamping unit offers excellent workability, while the affordable, low-maintenance design ensures long-lasting precision and low running costs.

Click the dropdowns below to view detailed specifications for each model in the STX Series.

| Item | Unit | 2V |

|---|---|---|

| Screw diameter | inch (mm) | 0.63 (16) 0.75 (19) 0.87 (22) |

| Injection capacity | inch³ (cm³) (oz) | 0.8 (13) (0.4) 1.1 (18) (0.6) 1.5 (25) (0.8) |

| Max. injection pressure | psi (MPa) (kgf/cm²) | 38162 (263) (2684) 26989 (186) (1898) 20169 (139) (1418) |

| Clamping force | USton (kN) (tf) | 11 (94) 10 |

| Clamping stroke | inch (mm) | 6.7 (170) |

| Min. mold thickness | inch (mm) | 5.1 (130) |

| Max. daylight opening | inch (mm) | 11.8 (300) |

| Die plate dimensions (H×V) | inch (mm) | 15.7 × 7.9 (400 × 200) |

| Ejector stroke | inch (mm) | STX10 (Single-stage): 2.4 (60) STX10S (Sliding): 1.6 (40) STX10R (Turntable): 1.6 (40) |

| Item | Unit | 2V | 5V |

|---|---|---|---|

| Screw diameter | inch (mm) | 0.63 (16), 0.75 (19), 0.87 (22) | 0.87 (22), 1.02 (26), 1.18 (30) |

| Injection capacity | inch³ (cm³) (oz) | 0.8 (13) (0.4), 1.1 (18) (0.6), 1.5 (25) (0.8) | 2.1 (35) (1.2), 3.0 (49) (1.6), 4.0 (65) (2.2) |

| Max. injection pressure | psi (MPa) (kgf/cm²) | 38162 (263) (2684), 26989 (186) (1898), 20169 (139) (1418) | 37146 (256) (2612), 26554 (183) (1867), 20024 (138) (1408) |

| Clamping force | USton (kN) (tf) | 22 (193), 20 | 22 (193), 20 |

| Clamping stroke | inch (mm) | 7.9 (200) | 7.9 (200) |

| Min. mold thickness | inch (mm) | 5.9 (150) | 5.9 (150) |

| Max. daylight opening | inch (mm) | 13.8 (350) | 13.8 (350) |

| Die plate dimensions (H×V) | inch (mm) | 17.7 × 9.8 (450 × 250) | 17.7 × 9.8 (450 × 250) |

| Ejector stroke | inch (mm) | STX10 (Single-stage): 2.6 (65), STX10S (Sliding): 1.8 (45), STX10R (Turntable): 1.8 (45) | STX10 (Single-stage): 2.6 (65), STX10S (Sliding): 1.8 (45), STX10R (Turntable): 1.8 (45) |

A: The STX Series offers clamping forces ranging from 10 to 20 tons (11 to 22 U.S. tons), suitable for various molding applications.

A:The X-Pump® System combines hydraulic control with servomotor drive technologies, operating the servomotor only when necessary, resulting in significant energy savings.

A: The STX10 model has floor dimensions of 860mm x 850mm, and the STX20 measures 900mm x 1000mm, offering a compact footprint for flexible installation.

A: Yes, the STX Series is designed with excellent layout flexibility and automation adaptability, making it suitable for various automated production setups.

A: The STX Series features an affordable design with low maintenance costs and long-lasting precision, ensuring reliable operation and reduced downtime.