Automator’s Dot Peen Marking machines deliver precision and durability for permanent marking needs. Ideal for metal and plastic, they ensure consistent, high-quality engravings for industrial applications.

Dot Peen Marking is a versatile and cost-effective method for creating permanent, legible marks on various materials. Widely used in industries like automotive, aerospace, and manufacturing, it delivers precision and consistency. The technique uses a stylus to indent surfaces with controlled impact, ideal for tracking and traceability in industrial settings.

Automator’s Dot Peen Marking systems stand out with their precision, speed, and adaptability. They feature adjustable marking depths, robust styluses for longevity, and advanced software for seamless integration. Capable of marking metals, plastics, and uneven surfaces, these machines ensure clear, durable marks essential for compliance and traceability.

Dot Peen Marking offers unmatched efficiency, reducing marking time while delivering permanent results. Its non-invasive nature preserves material integrity, ensuring durability in industrial environments. With Automator’s advanced systems, users gain reliability, ease of use, and compliance with industry standards, boosting productivity.

Click the dropdowns below to view detailed information for each model in the Dot Peen Marking.

| ADP120160 Portable Dot Peen Marker | |

|---|---|

| Marking Area | 120 x 160 mm |

| Dimensions (W x D x H) | 365 x 271 x 125 mm |

| Weight | 8.5 kg |

| Drive Mechanism | Pneumatic, spring-return, and electric solenoid tip |

| Marking Modes | Controlled-point for deep and fast marking; vibratory for high-quality marking |

| Compatible Materials | Metals, alloys, plastics, wood, ceramics, and more |

| Controller Options | AC500 (7″ color touch screen); AC250 (basic version) |

| Connectivity | Ethernet, RS232-485, USB, I/O |

| Software Features | Management of serial numbers, texts, geometric figures, date codes, TTF fonts, Datamatrix, QR codes, and more |

| ADP5090 Benchtop Dot Peen Marker | |

|---|---|

| Marking Area | 50 x 90 mm |

| Dimensions (W x D x H) | 180 x 150 x 121 mm |

| Weight | 5 kg |

| Drive Mechanism | Pneumatic, spring-return, and electric solenoid tip |

| Marking Modes | Controlled-point for deep and fast marking; vibratory for high-quality marking |

| Compatible Materials | Metals, alloys, plastics, wood, ceramics, and more |

| Controller Options | AC500 (7″ color touch screen); AC250 (basic version) |

| Connectivity | Ethernet, RS232-485, USB, I/O |

| Software Features | Management of serial numbers, texts, geometric figures, date codes, TTF fonts, Datamatrix, QR codes, and more |

| ADP2560BA Battery-Powered Portable Dot Peen Marker | |

|---|---|

| Marking Area | 25 x 60 mm |

| Dimensions (W x D x H) | 136 x 266 x 304 mm |

| Weight | 3 kg |

| Power Supply | 18V Battery-Powered |

| Drive Mechanism | Electric solenoid tip |

| Marking Modes | Controlled-point for deep and fast marking; vibratory for high-quality marking |

| Compatible Materials | Metals, alloys, plastics, wood, ceramics, and more |

| Controller | Integrated with graphical touch screen display |

| Software Features | Management of serial numbers, texts, geometric figures, date codes, TTF fonts, Datamatrix, QR codes, and more |

| ADP25120 Benchtop Dot Peen Marker | |

|---|---|

| Marking Area | 25 x 120 mm |

| Dimensions (W x D x H) | 409 x 618 x 315 mm |

| Weight | 4 kg |

| Drive Mechanism | Pneumatic, spring-return, and electric solenoid tip |

| Marking Modes | Controlled-point for deep and fast marking; vibratory for high-quality marking |

| Compatible Materials | Metals, alloys, plastics, wood, ceramics, and more |

| Controller Options | AC500 (7″ color touch screen); AC250 (basic version) |

| Connectivity | Ethernet, RS232-485, USB, I/O |

| Software Features | Management of serial numbers, texts, geometric figures, date codes, TTF fonts, Datamatrix, QR codes, and more |

| ADP2560 Dot Peen Marker | |

|---|---|

| Marking Area | 25 x 60 mm |

| Dimensions (W x D x H) | 126 x 174.5 x 80 mm |

| Weight | 3 kg |

| Drive Mechanism | Pneumatic, spring-return, and electric solenoid tip |

| Marking Modes | Controlled-point for deep and fast marking; vibratory for high-quality marking |

| Compatible Materials | Metals, alloys, plastics, wood, ceramics, and more |

| Controller Options | AC500+ (7″ color touch screen); AC250 (basic version) |

| Connectivity | Ethernet, RS232-485, USB, I/O |

| Software Features | Management of serial numbers, texts, geometric figures, date codes, TTF fonts, Datamatrix, QR codes, and more |

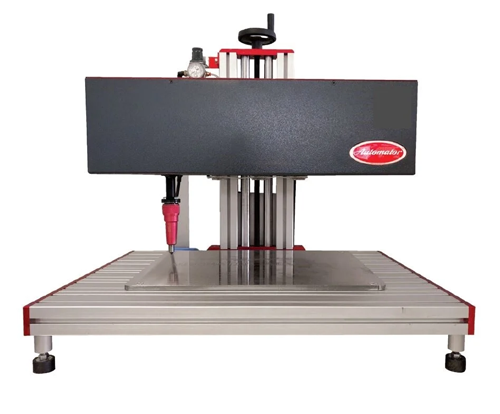

| ADP120160 Benchtop Dot Peen Marker | |

|---|---|

| Marking Area | 120 x 160 mm |

| Dimensions (W x D x H) | 409 x 618 x 315 mm |

| Weight | 8.5 kg |

| Drive Mechanism | Pneumatic, spring-return, and electric solenoid tip |

| Marking Modes | Controlled-point for deep and fast marking; vibratory for high-quality marking |

| Compatible Materials | Metals, alloys, plastics, wood, ceramics, and more |

| Controller Options | AC500 (7″ color touch screen); AC250 (basic version) |

| Connectivity | Ethernet, RS232-485, USB, I/O |

| Software Features | Management of serial numbers, texts, geometric figures, date codes, TTF fonts, Datamatrix, QR codes, and more |

| ADP300400 Benchtop Dot Peen Marker | |

|---|---|

| Marking Area | 300 x 400 mm |

| Dimensions (W x D x H) | Customizable based on configuration |

| Weight | Varies with configuration |

| Drive Mechanism | Pneumatic, spring-return, and electric solenoid tip |

| Marking Modes | Controlled-point for deep and fast marking; vibratory for high-quality marking |

| Compatible Materials | Metals, alloys, plastics, wood, ceramics, and more |

| Controller Options | AC500 (7″ color touch screen); AC250 (basic version) |

| Connectivity | Ethernet, RS232-485, USB, I/O |

| Software Features | Management of serial numbers, texts, geometric figures, date codes, TTF fonts, Datamatrix, QR codes, and more |

A: They can mark metals, plastics, and even uneven or rough surfaces effectively.

A: Yes, they are designed for high-speed, continuous use, ideal for high-volume production lines.

A: The machines deliver highly accurate marks, suitable for serial numbers, barcodes, and logos.

A: Automator’s Dot Peen systems feature advanced software, allowing seamless integration with industrial setups.

A:Minimal maintenance is needed due to their robust design, ensuring longevity and consistent performance.