ANCA SBG Range offers precision stick blade grinding for hypoid bevel gears with advanced automation, intuitive software, and robust design, ideal for automotive and industrial gear production.

The ANCA SBG Range is the ultimate solution for stick blade grinding, catering to the production and reconditioning of blades used in hypoid bevel gears. With robust construction, intuitive software, and full automation, the SBG ensures precision and quality for the automotive industry.

The SBG Range offers a bi-symmetrical gantry structure for stability, advanced blade-specific grinding cycles, and user-friendly Windows-based software. Equipped with RoboMate loaders and linear motor drives, it supports unmanned operations, ensuring consistent accuracy and efficiency.

The SBG Range delivers superior blade precision, reduced manual intervention, and enhanced productivity. Its automation capabilities minimize downtime, making it a reliable choice for manufacturers seeking high-quality stick blade grinding and seamless gear production.

Click the dropdowns below to view detailed specifications for the SBG Range.

| Specification | Unit | Details |

|---|---|---|

| Model | ANCA SBG | |

| Application | Stick Blade Grinding | |

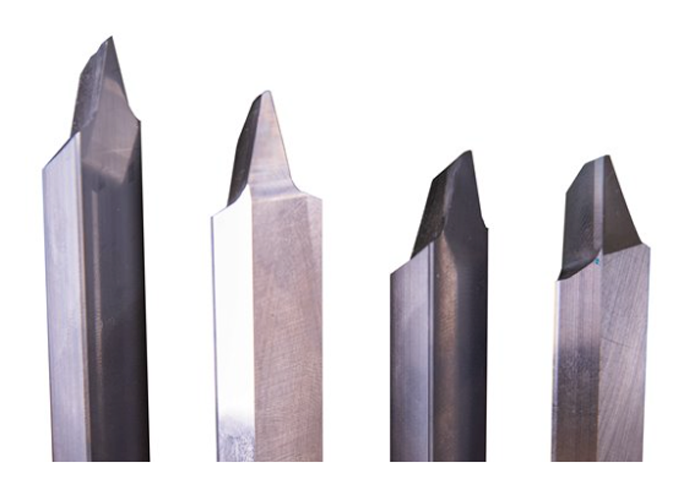

| Blade Types Supported | RSR, TRI-AC, ARCON, SPIRON, Pentac | |

| Max Blade Length | mm | 200 |

| Max Blade Height | mm | 50 |

| Grinding Motor Power | kW | 10 |

| Automation | RoboMate loader for unmanned operations | |

| Software | Windows-based with blade-specific cycles | |

| Construction | Bi-symmetrical gantry structure | |

| Key Features | High precision, efficient blade production |

A: It handles RSR, TRI-AC, ARCON, SPIRON, and Pentac blades.

A: Industry-standard files ensure precise stick blade geometry, with options for profile adjustments.

A: Yes, it supports data-driven geometry adjustments for accurate grinding.

A: RoboMate loaders enable continuous, unmanned blade production.

A: It grinds HSS and carbide stick blades efficiently.