The NEX-Ⅳ Series from Nissei delivers high-speed injection, energy-efficient operation, advanced control, and precision molding, making it ideal for versatile, high-performance manufacturing.

The NEX-Ⅳ Series by Nissei represents the latest advancement in all-electric injection molding machines, offering clamping forces from 30 to 360 tons (33 to 397 U.S. tons). Designed to enhance precision and efficiency, these machines cater to diverse manufacturing sectors, including automotive, medical devices, and consumer goods. The NEX-Ⅳ Series builds upon its predecessors’ success, incorporating innovative features to meet evolving industry demands.

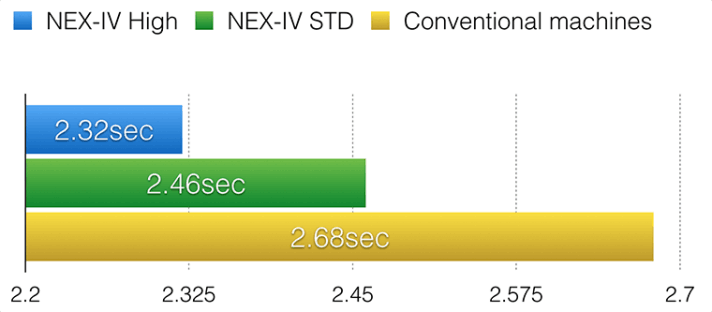

Key features of the NEX-Ⅳ Series include a newly designed toggle mechanism that reduces mold open/close cycle times by 5–20%, and an ejector speed up to 19% faster than previous models, significantly boosting productivity. The enhanced “Flat Clamp Mechanism” ensures uniform contact pressure, extending the lifespan of both the mold and clamping unit. Standard linear guides for clamping slides improve rectilinearity, preventing molding defects and ensuring high-precision operations.

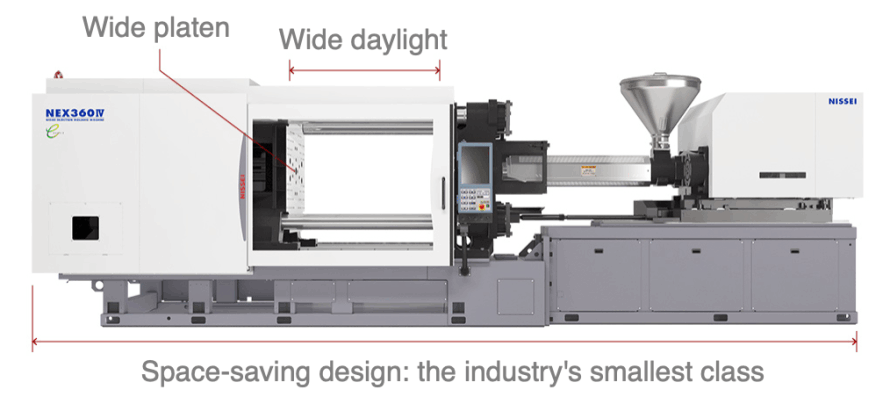

Choosing the NEX-Ⅳ Series offers substantial benefits, such as accommodating larger molds within a compact machine footprint, thanks to increased daylight and mold thickness ranges. This flexibility supports various mold types, including hot runner and long-length molds. The advanced “TACT® Ⅳ” controller, featuring a large 15-inch screen and user-friendly interface, enhances operability and facilitates efficient condition management, streamlining the molding process.

Click the dropdowns below to view detailed specifications for each model in the NEX-Ⅳ Series.

| Item | Unit | 2EG | 3EG |

|---|---|---|---|

| Screw Diameter | inch (mm) | A: 0.63 (16), B: 0.75 (19) | A: 0.75 (19), B: 0.87 (22) |

| Injection Capacity | inch³ (cm³) (oz) | 0.8 (13) (0.4), 1.1 (18) (0.6) | 1.4 (23) (0.8), 2.1 (35) (1.2) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 38,450 (265) (2704), 28,440 (196) (2000) | 38,450 (265) (2704), 30,470 (210) (2143) |

| Clamping Force | USton (kN) (tf) | 33 (294) (30) | Same as 2EG |

| Clamping Stroke | inch (mm) | 9.06 (230) | Same as 2EG |

| Mold Thickness (min-max) | inch (mm) | 5.91 | Same as 2EG |

| Max. Daylight Opening | inch (mm) | 23.8 (605) | Same as 2EG |

| Tie Bar Clearance (H×V) | inch (mm) | 12.2 x 12.2 (310 x 310) | Same as 2EG |

| Die Plate Dimensions (H×V) | inch (mm) | 17.7 x 17.7 (450 x 450) | Same as 2EG |

| Ejector Stroke | inch (mm) | 1.97 (50) | Same as 2EG |

| Item | Unit | 3EG | 5EG |

|---|---|---|---|

| Screw Diameter | inch (mm) | A: 0.75 (19), B: 0.87 (22) | A: 0.87 (22), B: 1.02 (26), BB: 1.10 (28) |

| Injection Capacity | inch³ (cm³) (oz) | 1.4 (23) (0.8), 2.1 (35) (1.2) | 2.1 (35) (1.2), 3.0 (49) (1.6), 3.5 (57) (1.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 38,450 (265) (2704), 30,470 (210) (2143) | 40,630 (280) (2857), 28,440 (196) (2000), 24,520 (169) (1725) |

| Clamping Force | USton (kN) (tf) | 55 (490) (50) | Same as 3EG |

| Clamping Stroke | inch (mm) | 9.84 (250) | Same as 3EG |

| Mold Thickness (min.-max.) | inch (mm) | 5.91 | Same as 3EG |

| Max. Daylight Opening | inch (mm) | 28.0 (710) | Same as 3EG |

| Tie Bar Clearance (H×V) | inch (mm) | 14.2 x 14.2 (360 x 360) | Same as 3EG |

| Die Plate Dimensions (H×V) | inch (mm) | 19.9 x 19.9 (505 x 505) | Same as 3EG |

| Ejector Stroke | inch (mm) | 2.95 (75) | Same as 3EG |

| Item | Unit | 5EG | 9EG | 12EG |

|---|---|---|---|---|

| Screw Diameter | inch (mm) | A: 0.87 (22), B: 1.02 (26), BB: 1.10 (28) | AA: 1.02 (26), A: 1.10 (28), B: 1.26 (32) | AA: 1.10 (28), A: 1.26 (32), B: 1.42 (36) |

| Injection Capacity | inch³ (cm³) (oz) | 2.1 (35) (1.2), 3.0 (49) (1.6), 3.5 (57) (1.9) | 3.3 (54) (1.8), 4.2 (69) (2.3), 5.5 (90) (3.0) | 4.2 (69) (2.3), 6.2 (101) (3.4), 7.7 (127) (4.3) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40,630 (280) (2857), 28,440 (196) (2000), 24,520 (169) (1725) | 40,630 (280) (2857), 35,260 (243) (2480), 26,990 (186) (1898) | 40,630 (280) (2857), 32,360 (223) (2276), 25,680 (177) (1806) |

| Clamping Force | USton (kN) (tf) | 88 (784) (80) | Same as 5EG | Same as 5EG |

| Clamping Stroke | inch (mm) | 11.8 (300) | Same as 5EG | Same as 5EG |

| Mold Thickness (min.-max.) | inch (mm) | 5.91 | Same as 5EG | Same as 5EG |

| Max. Daylight Opening | inch (mm) | 30.9 (785) | Same as 5EG | Same as 5EG |

| Tie Bar Clearance (H×V) | inch (mm) | 16.5 x 16.5 (420 x 420) | Same as 5EG | Same as 5EG |

| Die Plate Dimensions (H×V) | inch (mm) | 22.8 x 22.8 (580 x 580) | Same as 5EG | Same as 5EG |

| Ejector Stroke | inch (mm) | 2.95 (75) | Same as 5EG | Same as 5EG |

| Item | Unit | 9EG | 12EG | 18E |

|---|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.02 (26), A: 1.10 (28), B: 1.26 (32) | AA: 1.10 (28), A: 1.26 (32), B: 1.42 (36) | AA: 1.26 (32), A: 1.42 (36), B: 1.57 (40) |

| Injection Capacity | inch³ (cm³) (oz) | 3.3 (54) (1.8), 4.2 (69) (2.3), 5.5 (90) (3.0) | 4.2 (69) (2.3), 6.2 (101) (3.4), 7.8 (127) (4.3) | 7.1 (117) (3.9), 9.0 (148) (5.0), 11.1 (182) (6.1) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40,630 (280) (2857), 35,260 (243) (2480), 26,990 (186) (1898) | 40,630 (280) (2857), 32,360 (223) (2276), 25,680 (177) (1806) | 40,050 (276) (2816), 31,630 (218) (2225), 25,680 (177) (1806) |

| Clamping Force | USton (kN) (tf) | 121 (1080) (110) | Same as 9EG | Same as 9EG |

| Clamping Stroke | inch (mm) | 13.8 (350) | Same as 9EG | Same as 9EG |

| Mold Thickness (min.-max.) | inch (mm) | 7.09 | Same as 9EG | Same as 9EG |

| Max. Daylight Opening | inch (mm) | 33.9 (860) | Same as 9EG | Same as 9EG |

| Tie Bar Clearance (H×V) | inch (mm) | 18.1 x 18.1 (460 x 460) | Same as 9EG | Same as 9EG |

| Die Plate Dimensions (H×V) | inch (mm) | 25.5 x 25.5 (647 x 647) | Same as 9EG | Same as 9EG |

| Ejector Stroke | inch (mm) | 3.94 (100) | Same as 9EG | Same as 9EG |

| Item | Unit | 12EG | 18E | 25E |

|---|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.10 (28), A: 1.26 (32), B: 1.42 (36) | AA: 1.26 (32), A: 1.42 (36), B: 1.57 (40) | AA: 1.42 (36), A: 1.57 (40), B: 1.70 (45) |

| Injection Capacity | inch³ (cm³) (oz) | 4.2 (69) (2.3), 6.2 (101) (3.4), 7.7 (127) (4.3) | 7.1 (117) (3.9), 9.0 (148) (5.0), 11.1 (182) (6.1) | 9.9 (163) (5.5), 12.3 (201) (6.7), 15.5 (254) (8.5) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40,630 (280) (2857), 32,360 (223) (2276), 25,680 (177) (1806) | 40,050 (276) (2816), 31,630 (218) (2225), 25,680 (177) (1806) | 37,870 (261) (2663), 30,620 (211) (2153), 24,230 (167) (1704) |

| Clamping Force | USton (kN) (tf) | 154 (1373) (140) | Same as 12EG | Same as 12EG |

| Clamping Stroke | inch (mm) | 15.7 (400) | Same as 12EG | Same as 12EG |

| Mold Thickness (min.-max.) | inch (mm) | 7.09 | Same as 12EG | Same as 12EG |

| Max. Daylight Opening | inch (mm) | 37.4 (950) | Same as 12EG | Same as 12EG |

| Tie Bar Clearance (H×V) | inch (mm) | 20.1 x 20.1 (510 x 510) | Same as 12EG | Same as 12EG |

| Die Plate Dimensions (H×V) | inch (mm) | 28.3 x 28.3 (720 x 720) | Same as 12EG | Same as 12EG |

| Ejector Stroke | inch (mm) | 4.72 (120) | Same as 12EG | Same as 12EG |

| Item | Unit | 18E | 25E | 36E |

|---|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.26 (32), A: 1.42 (36), B: 1.57 (40) | AA: 1.42 (36), A: 1.57 (40), B: 1.77 (45) | AA: 1.57 (40), A: 1.77 (45), B: 1.97 (50) |

| Injection Capacity | inch³ (cm³) (oz) | 7.1 (117) (3.9), 9.0 (148) (5.0), 11.1 (182) (6.1) | 9.95 (163) (5.5), 12.3 (201) (6.7), 15.5 (254) (8.5) | 13.8 (226) (7.6), 17.5 (286) (9.6), 21.5 (353) (11.8) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40,050 (276) (2816), 31,620 (218) (2224), 25,680 (177) (1806) | 37,870 (261) (2663), 30,620 (211) (2153), 24,230 (167) (1704) | 37,730 (260) (2653), 29,890 (206) (2102), 24,230 (167) (1704) |

| Clamping Force | USton (kN) (tf) | 198 (1765) (180) | Same as 18E | Same as 18E |

| Clamping Stroke | inch (mm) | 17.7 (450) | Same as 18E | Same as 18E |

| Mold Thickness (min.-max.) | inch (mm) | 6.89 | Same as 18E | Same as 18E |

| Max. Daylight Opening | inch (mm) | 40.7 (1035) | Same as 18E | Same as 18E |

| Tie Bar Clearance (H×V) | inch (mm) | 22.0 x 22.0 (560 x 560) | Same as 18E | Same as 18E |

| Die Plate Dimensions (H×V) | inch (mm) | 31.5 x 31.5 (800 x 800) | Same as 18E | Same as 18E |

| Ejector Stroke | inch (mm) | 5.91 (150) | Same as 18E | Same as 18E |

| Item | Unit | 50E | 71E |

|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.77 (45), A: 1.97 (50), B: 2.20 (56) | AA: 1.97 (50), A: 2.20 (56), B: 2.48 (63) |

| Injection Capacity | inch³ (cm³) (oz) | 19.9 (326) (10.9), 24.6 (403) (13.5), 30.8 (505) (16.9) | 27.0 (442) (14.8), 33.8 (554) (18.6), 42.8 (701) (23.5) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36,280 (250) (2551), 29,310 (202) (2061), 23,360 (161) (1643) | 36,130 (249) (2541), 28,880 (199) (2031), 22,780 (157) (1602) |

| Clamping Force | USton (kN) (tf) | 243 (2160) (220) | Same as 50E |

| Clamping Stroke | inch (mm) | 21.7 (550) | Same as 50E |

| Mold Thickness (min.-max.) | inch (mm) | 10.8 | Same as 50E |

| Max. Daylight Opening | inch (mm) | 48.4 (1230) | Same as 50E |

| Tie Bar Clearance (H×V) | inch (mm) | 26.0 x 24.0 (660 x 610) | Same as 50E |

| Die Plate Dimensions (H×V) | inch (mm) | 36.2 x 34.3 (920 x 870) | Same as 50E |

| Ejector Stroke | inch (mm) | 5.91 (150) | Same as 50E |

| Item | Unit | 71E | 100LE |

|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.97 (50), A: 2.20 (56), B: 2.48 (63) | AA: 1.97 (50), A: 2.20 (56), B: 2.48 (63) |

| Injection Capacity | inch³ (cm³) (oz) | 27.0 (442) (14.8), 33.8 (554) (18.6), 42.8 (701) (23.5) | 33.6 (550) (18.4), 47.4 (776) (26.0), 59.9 (982) (32.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36,130 (249) (2541), 28,880 (199) (2031), 22,780 (157) (1602) | 36,130 (249) (2541), 28,880 (199) (2031), 22,780 (157) (1602) |

| Clamping Force | USton (kN) (tf) | 308 (2740) (280) | Same as 71E |

| Clamping Stroke | inch (mm) | 23.6 (600) | Same as 71E |

| Mold Thickness (min.-max.) | inch (mm) | 11.8 | Same as 71E |

| Max. Daylight Opening | inch (mm) | 53.1 (1350) | Same as 71E |

| Tie Bar Clearance (H×V) | inch (mm) | 29.9 x 26.0 (760 x 660) | Same as 71E |

| Die Plate Dimensions (H×V) | inch (mm) | 41.5 x 37.6 (1055 x 955) | Same as 71E |

| Ejector Stroke | inch (mm) | 5.91 (150) | Same as 71E |

| Item | Unit | 100LE |

|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.97 (50), A: 2.20 (56), B: 2.48 (63) |

| Injection Capacity | inch³ (cm³) (oz) | 33.6 (550) (18.4), 47.4 (776) (26.0), 59.9 (982) (32.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36,130 (249) (2541), 28,880 (199) (2031), 22,780 (157) (1602) |

| Clamping Force | USton (kN) (tf) | 397 (3530) (360) |

| Clamping Stroke | inch (mm) | 25.6 (650) |

| Mold Thickness (min.-max.) | inch (mm) | 11.8 x 31.1 (300~790) |

| Max. Daylight Opening | inch (mm) | 56.7 (1440) |

| Tie Bar Clearance (H×V) | inch (mm) | 31.9 x 29.9 (810 x 760) |

| Die Plate Dimensions (H×V) | inch (mm) | 44.5 x 42.5 (1130 x 1080) |

| Ejector Stroke | inch (mm) | 7.87 (200) |

A: The NEX-Ⅳ Series offers clamping forces ranging from 30 to 360 tons (33 to 397 U.S. tons), suitable for various manufacturing requirements.

A: The redesigned toggle mechanism reduces mold open/close cycle times by 5–20%, and the ejector operates up to 19% faster, enhancing overall production efficiency.

A: The improved “Flat Clamp Mechanism” ensures even contact pressure, prolonging the service life of the mold and clamping unit, and improving product quality.

A: Yes, the series offers one of the widest daylights in the industry, with increased mold thickness ranges, allowing it to flexibly accommodate larger and more complex molds.

A: The “TACT® Ⅳ” controller features a large 15-inch screen and a user-friendly interface, enhancing operability and facilitating efficient management of molding conditions and processes.