The TH-EⅢ Series from Nissei offers high-cycle thin hoop molding, energy-efficient operation, precise control, and user-friendly features, making it ideal for advanced injection molding applications.

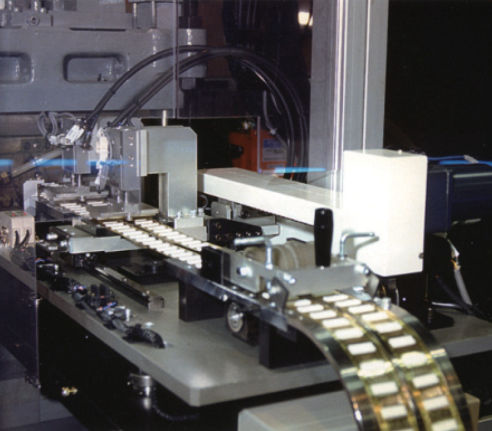

The TH-EⅢ Series from Nissei comprises all-electric vertical injection molding machines with clamping forces ranging from 20 to 80 tons (22 to 88 U.S. tons). These machines are engineered for high-cycle thin hoop molding applications, offering superior energy efficiency and precision. Equipped with the advanced TACT® Ⅳ Controller, they enhance user convenience and operational efficiency.

Key features of the TH-EⅢ Series include a high-speed, high-response injection unit that expands moldable ranges, addressing diverse customer needs. The machines are designed with safety and operability in mind, incorporating functions that enable high-cycle molding to boost productivity. Users can select between air-driven ejectors for rapid cycles and hydraulic-driven ejectors for greater force, depending on molding requirements.

Choosing the TH-EⅢ Series offers significant benefits, such as reduced energy consumption due to its all-electric design, leading to lower operational costs. The machines provide clean and precise operation, making them ideal for environments requiring minimal contamination. The user-friendly TACT® Ⅳ Controller simplifies setup and operation, enhancing overall productivity and product quality.

Click the dropdowns below to view detailed specifications for each model in the TH-EⅢ Series.

| Item | Unit | 2VE |

|---|---|---|

| Screw Diameter | inch (mm) | 0.63 (16), 0.75 (19) |

| Injection Capacity | inch³ (cm³) (oz) | 0.8 (13) (0.4), 1.1 (18) (0.6) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36,970 (255) (2600), 28,440 (196) (2000) |

| Clamping Force | USton (kN) (tf) | 22 (196) (20) |

| Clamping Stroke | inch (mm) | 7.9 (200) |

| Mold Thickness (min-max) | inch (mm) | 6.7 |

| Max. Daylight Opening | inch (mm) | 18.5 (470) |

| Tie Bar Clearance (H×V) | inch (mm) | 12.2 x 12.2 (310 x 310) |

| Die Plate Dimensions (H×V) | inch (mm) | 18.1 x 18.1 (460 x 460) |

| Ejector Stroke | inch (mm) | 1.6 (40) |

| Item | Unit | 5VE |

|---|---|---|

| Screw Diameter | inch (mm) | 0.75 (19), 0.87 (22), 1.02 (26) |

| Injection Capacity | inch³ (cm³) (oz) | 1.4 (23) (0.8), 2.1 (35) (1.2), 3.0 (49) (1.6) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 38,400 (265) (2700), 36,970 (255) (2600), 28,440 (196) (2000) |

| Clamping Force | USton (kN) (tf) | 44 (392) (40) |

| Clamping Stroke | inch (mm) | 9.4 (240) |

| Mold Thickness (min-max) | inch (mm) | 9.5 |

| Max. Daylight Opening | inch (mm) | 20.9 (530) |

| Tie Bar Clearance (H×V) | inch (mm) | 14.2 x 14.2 (360 x 360) |

| Die Plate Dimensions (H×V) | inch (mm) | 20.5 x 20.5 (520 x 520) |

| Ejector Stroke | inch (mm) | 1.6 (40) |

| Item | Unit | 5VE | 9VE |

|---|---|---|---|

| Screw Diameter | inch (mm) | 0.75 (19), 0.87 (22), 1.02 (26) | 1.10 (28), 1.26 (32) |

| Injection Capacity | inch³ (cm³) (oz) | 1.4 (23) (0.8), 2.1 (35) (1.2), 3.0 (49) (1.6) | 4.2 (69) (2.3), 5.5 (90) (3.0) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 38,400 (265) (2700), 36,970 (255) (2600), 28,440 (196) (2000) | 35,270 (243) (2480), 27,020 (186) (1900) |

| Clamping Force | USton (kN) (tf) | 77 *(88) (686) *(784) (70) *(80) | Same as 5VE |

| Clamping Stroke | inch (mm) | 9.8 (250) | Same as 5VE |

| Mold Thickness (min-max) | inch (mm) | 9.1 | Same as 5VE |

| Max. Daylight Opening | inch (mm) | 23.6 (600) | Same as 5VE |

| Tie Bar Clearance (H×V) | inch (mm) | 16.5 x 16.5 (420 x 420) | Same as 5VE |

| Die Plate Dimensions (H×V) | inch (mm) | 23.9 x 23.9 (607 x 607) | Same as 5VE |

| Ejector Stroke | inch (mm) | 2.4 (60) | Same as 5VE |

A: The series offers clamping forces ranging from 20 to 80 tons (22 to 88 U.S. tons), accommodating various molding requirements.

A: The TACT® Ⅳ Controller features a 15-inch vertical LCD that can display two windows simultaneously, enhancing visibility and user-friendliness. It automates and simplifies molding condition settings, reducing defect rates and preparation time.

A: All-electric machines offer energy savings, clean operation, high-precision control, and suitability for high-cycle molding, making them ideal for various applications.

A: Yes, the series is designed for easy interfacing and integration with insert robots, facilitating automation and rationalization of production processes.

A: Users can choose between air-driven ejectors for high-cycle molding and hydraulic-driven ejectors for applications requiring stronger force, depending on their specific molding needs.