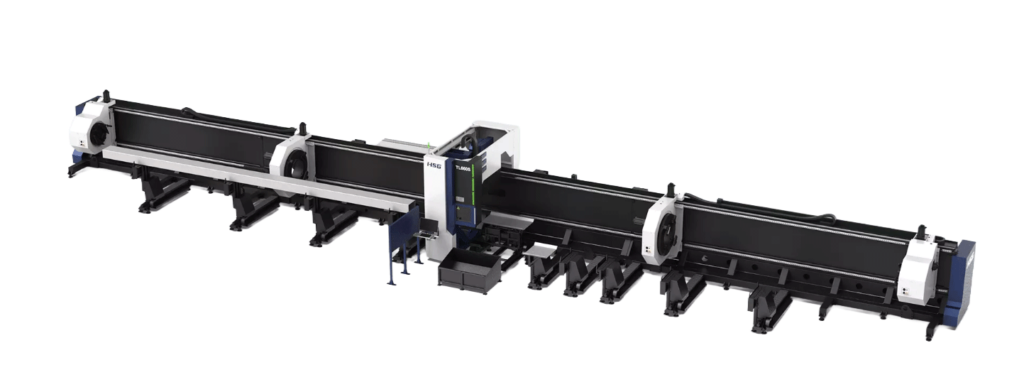

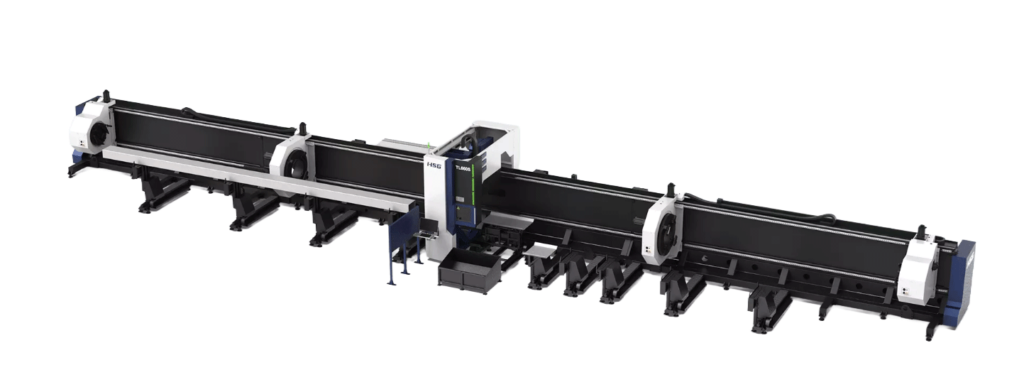

The TL Series by HSG Laser delivers precise tube cutting performance with intelligent automation and powerful configurations for round, square, and special-shaped metal tubes.

Tube laser cutting machines like the TL Series from HSG Laser are essential in modern fabrication, offering precise and efficient processing of metal tubing. This category plays a key role across automotive, furniture, construction, and fitness industries, helping manufacturers meet tight tolerances and improve production throughput.

The TL Series features auto-loading, bevel cutting, high-speed servo motors, and support for complex tube profiles. With multiple model options and intelligent control systems, it ensures clean, fast, and flexible tube processing—ideal for heavy-duty and precision-demanding applications.

Customers benefit from faster production cycles, reduced labor, and consistent high-quality cuts. TL machines are ideal for scaling operations and optimizing fabrication efficiency in tube processing.

Click the dropdowns below to view detailed specifications for the TL Series.

Specification | Metric | Imperial |

Laser Power | 6kW – 20kW | 6000W – 20000W |

Tube Processing Range | TL660 Round tube: 80mm – 660mm Square tube: 80mm x 80mm – 450mm x 450mm Diagonal≤660mm Side Length≥80mm TL730S Round tube: 120mm- 715mm Square tube: 120mm x 120mm – 500mm x 500mm Diagonal≤715mm Side Length: 120mm-500mm | TL660 Round tube: 3.15” – 25.98in Square tube: 3.15in x 3.15in – 17.72in x 17.72in Diagonal≤25.98in Side Length≥3.15in TL730S Round tube: 4.72in – 28.15in Square tube: 4.72in x 4.72in – 19.69in x 19.69in Diagonal≤28.15in Side Length: 4.72in – 19.69in |

Range of Incoming Materials for Tube | 3000mm – 12000mm (TL660) 3000mm – 16000mm (TL730S) | 118.11in – 472.44in (TL660) 118.11in – 629.92in (TL730S) |

Positioning Precision of X/Y Axis | ±0.01mm/m | ±0.00012 in/ft |

Repetitive Positioning Precision of X/Y Axis | ±0.01mm | ±0.00039 in |

Speed of Chuck | 30 RPM | |

Max Linkage Speed | 50m/min (TL660) 45m/min (TL730S) | 164ft/min (TL660) 147.6ft/min (TL730S) |

Max Linkage Acceleration | 0.2 G | |

Max Single Tube Weight | About 3000kg (TL660) About 4000kg (TL730S) | About 6614lb (TL660) About 8818lb (TL730S) |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

Core Attributes | Four-Chuck Tube Laser Cutter for Heavy-Duty Applications: Engineered for ultra-stable processing of long, large-diameter tubes Zero-Tail Cutting Capability: Maximizes material usage by eliminating waste at the tube end Optional Automated Handling: Supports automatic loading and unloading systems designed specifically for heavy tube operations | |

A: The TL Series supports round, square, rectangular, oval, and special-shaped tubes for diverse industrial applications.

A: Yes, TL models include intelligent automatic loading and unloading systems, streamlining operations and reducing manual labor.

A: Cutting speed depends on the model and material but is optimized with servo motors and HSG’s high-precision drive system for fast throughput.

A: Yes, specific TL models like the TLS support bevel cutting for advanced tube assembly requirements.

A: Yes, HSG’s TL Series integrates with CAD/CAM systems and includes user-friendly CNC controls for efficient operation and programming.