The X-Caliber from VECTOR INJECTION delivers rapid mold changes, flexible clamping, superior efficiency, advanced safety, and cost-saving solutions, ensuring peak productivity in injection molding.

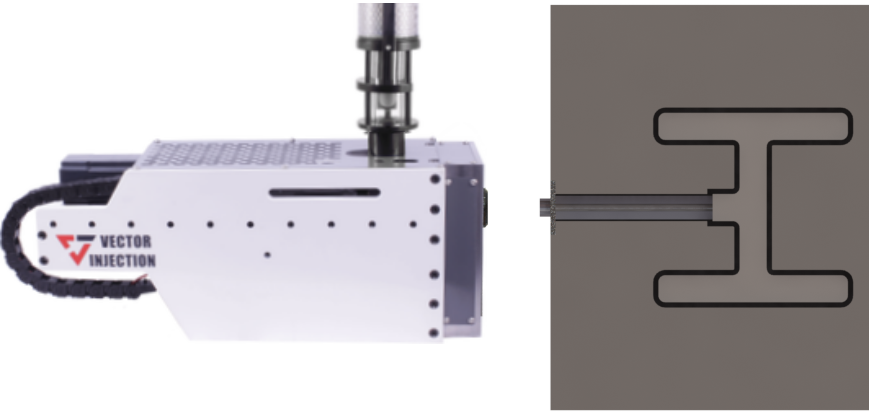

The X-Caliber from VECTOR INJECTION is a compact, mold-mounted injection unit featuring a single-stage, reciprocating screw design that upholds the first-in, first-out (FIFO) principle. Its robust, simplified melt path minimizes maintenance requirements. Measuring less than 6 inches in width, the X-Caliber-SS is the most compact injection unit available, requiring only 3 inches of mold height when mounted parallel to the injection molding machine platen.

Key features of the X-Caliber include a patent-pending split barrel with the exit permanently fixed to the mold’s hot runner manifold, typically near the centerline. This design reduces flow length, pressure drop, shear, and material residence time within the hot runner system. The screw fully retracts into the injection unit housing, facilitating easy assembly to the mold and efficient mechanical screw cleaning, which is advantageous for quick color changes.

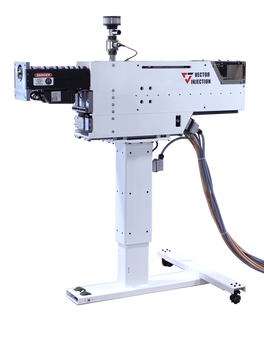

Choosing the X-Caliber offers manufacturers a compact, self-supported injection unit that doesn’t require additional support structures, thereby conserving valuable floor space. Its innovative design ensures efficient material flow and simplifies maintenance, leading to increased productivity and reduced downtime. The unit’s ease of integration and operation makes it a versatile solution for various injection molding applications.

Click the dropdowns below to view detailed specifications for the X-Caliber.

| Parameter | 14 mm | 16 mm | 18 mm (#1) | 18 mm (#2) | 20 mm | 22 mm | 24 mm (#1) | 24 mm (#2) | 26 mm | 30 mm |

|---|---|---|---|---|---|---|---|---|---|---|

| Injection Volume (cc) | 12 | 16 | 23 | 23 | 31 | 42 | 57 | 57 | 77 | 102 |

| Injection Volume (in³) | 0.8 | 1.0 | 1.4 | 1.4 | 1.9 | 2.6 | 3.5 | 3.5 | 4.7 | 6.3 |

| Max Injection Pressure (bar) | 1600 | 1200 | 1000 | 2000 | 1600 | 1300 | 1100 | 2000 | 1700 | 1250 |

| Max Injection Pressure (psi) | 23500 | 18000 | 14000 | 28500 | 23000 | 19000 | 16000 | 29000 | 24500 | 18500 |

| Screw Stroke (mm) | 80 | 80 | 90 | 90 | 100 | 110 | 125 | 125 | 145 | 145 |

| Screw Stroke (in) | 3.15 | 3.15 | 3.54 | 3.54 | 3.94 | 4.33 | 4.92 | 4.92 | 5.71 | 5.71 |

| Injection Speed (cc/s) | 23.1 | 30.2 | 38.2 | 42.0 | 51.8 | 62.7 | 74.6 | 90.5 | 106.2 | 141.4 |

| Injection Speed (in³/s) | 1.4 | 1.8 | 2.3 | 2.6 | 3.2 | 3.8 | 4.6 | 5.5 | 6.5 | 8.6 |

| Plast Screw RPM | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Screw Torque (Nm) | 37.9 | 37.9 | 52.1 | 52.1 | 69.3 | 69.3 | 69.3 | 69.3 | 69.3 | 69.3 |

| Screw Torque (ft-lb) | 28.0 | 28.0 | 38.4 | 38.4 | 51.1 | 51.1 | 51.1 | 51.1 | 51.1 | 51.1 |

| L/D Ratio | 15.7 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.2 | 15.2 | 15.6 | 14.8 |

A: The single-stage, reciprocating screw design maintains the first-in, first-out (FIFO) principle, ensuring consistent material quality and reducing degradation.

A:Measuring less than 6 inches in width and requiring only 3 inches of mold height when mounted parallel to the platen, the X-Caliber-SS facilitates easy integration without significant modifications.

A: The split barrel, fixed to the mold’s hot runner manifold, reduces flow length, pressure drop, shear, and material residence time, enhancing overall molding efficiency.

A: The fully retractable screw design allows for straightforward mechanical cleaning, enabling efficient color changes and reducing downtime.

A: No, the X-Caliber is self-supported when fixed to the mold, eliminating the need for extra supports and conserving valuable floor space.