Multi-Turret Lathes from Spinner CNC provide high-performance machining solutions, enhancing productivity with simultaneous multi-tool operation. Designed for precision, efficiency, and reliability.

Multi-turret lathes are essential in modern manufacturing, enabling simultaneous machining processes to reduce cycle times and enhance efficiency. Spinner CNC’s advanced multi-turret lathes integrate cutting-edge technology to meet industry demands for high precision and reliability. These machines optimize workflows by allowing multiple tools to operate simultaneously, improving output and reducing costs in automotive, aerospace, and medical industries.

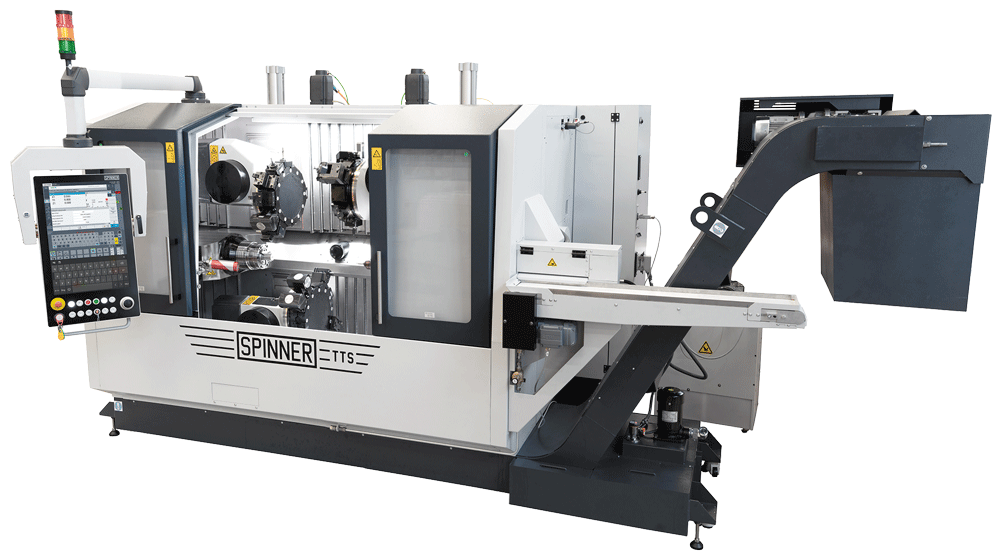

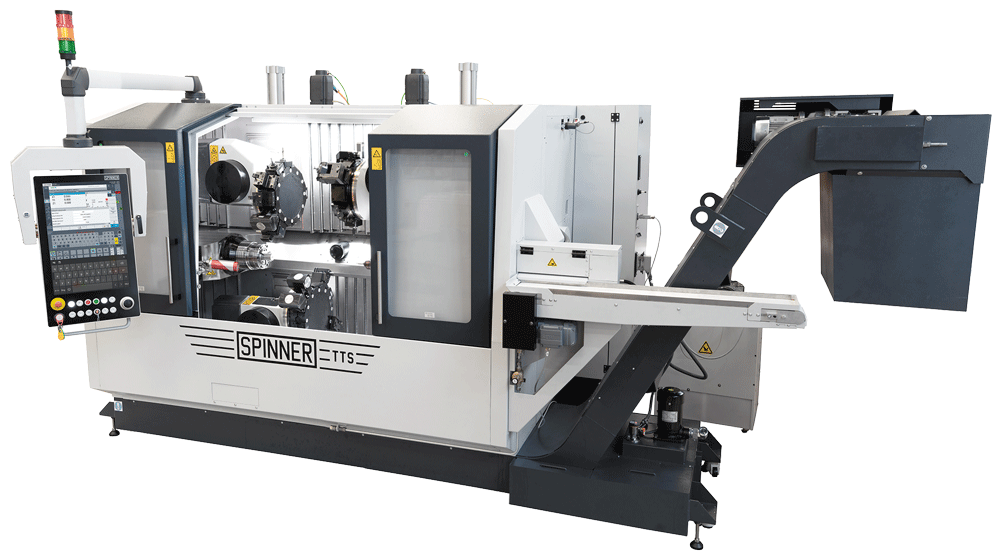

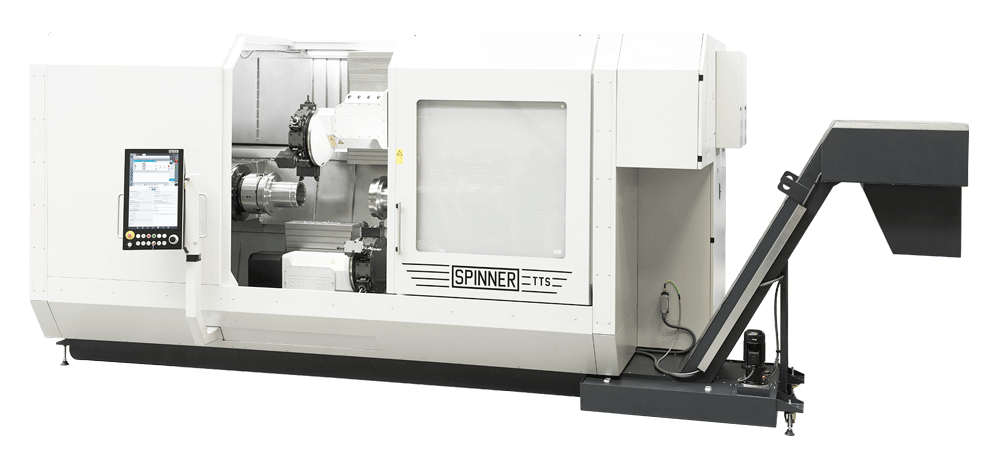

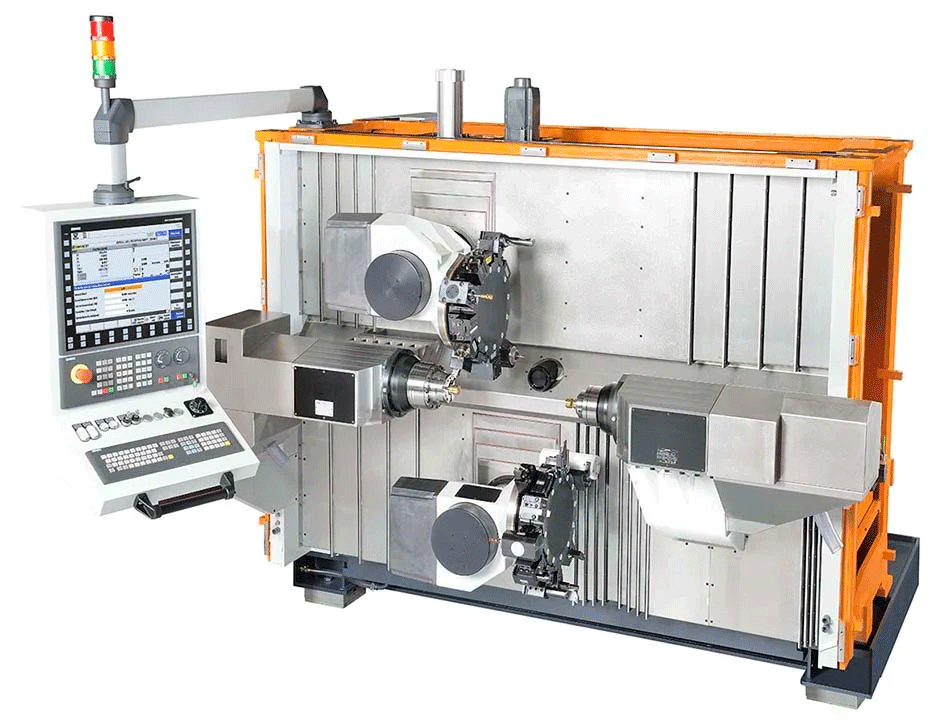

Spinner CNC’s multi-turret lathes offer unparalleled precision, rigidity, and automation. Featuring synchronized turrets, high-speed spindles, and advanced CNC controls, these machines enable complex part production with minimal downtime. The ability to perform simultaneous operations reduces cycle times while maintaining exceptional accuracy. Designed for versatility, they accommodate various materials and production scales, making them ideal for high-volume and precision manufacturing needs.

Multi-turret lathes significantly boost productivity by performing multiple machining tasks at once, minimizing idle time and increasing throughput. Their robust construction ensures precision and longevity, reducing maintenance costs. These machines are ideal for industries requiring complex geometries, delivering high-quality results while optimizing operational efficiency. With enhanced automation, manufacturers achieve faster turnaround times and improved overall profitability.

Click the dropdowns below to view detailed specifications for the Multi Turret Lathes.

| TTS65 Duplex / Triplex Specifications | |

|---|---|

| Machine Type | Multi-Turret CNC Lathe |

| Turret Configuration | Duplex (Two Turrets) / Triplex (Three Turrets) |

| Bar Capacity | 65 mm |

| Turning Length | 600 mm |

| Turning Diameter | 250 mm |

| X-Axis Travel | 180 mm |

| Y-Axis Travel | ±45 mm |

| Z-Axis Travel | 704 mm |

| Spindle Speed | Up to 5,000 rpm |

| Spindle Bore | 65 mm |

| Spindle Motor Power | 24 kW |

| Sub-Spindle | Optional |

| Number of Turrets | 2 or 3 |

| Turret Positions | 12 per turret |

| Live Tooling Speed | Up to 8,000 rpm |

| Tool Holder Type | BMT45 or VDI25 |

| Machine Dimensions (L×W×H) | 2,500 mm × 2,300 mm × 2,300 mm |

| Machine Weight | Approximately 7,500 kg |

| Control System | FANUC Series 31i-Model A |

| Automation | Compatible with Robobox |

| TTS85 Duplex / Triplex / Quadrex Specifications | |

|---|---|

| Machine Type | Multi-Turret CNC Lathe |

| Turret Configuration | Duplex (Two Turrets) / Triplex (Three Turrets) / Quadrex (Four Turrets) |

| Bar Capacity | 85 mm |

| Turning Length | 1,250 mm |

| Turning Diameter | 585 mm |

| X-Axis Travel | 310 mm |

| Y-Axis Travel | 200 mm |

| Z-Axis Travel | 1,250 mm |

| Spindle Speed | Up to 4,000 rpm |

| Spindle Bore | 85 mm |

| Sub-Spindle | Optional |

| Number of Turrets | 2, 3, or 4 |

| Turret Positions | 12 per turret |

| Live Tooling | Available |

| Tool Holder Type | BMT45 or VDI25 |

| Machine Dimensions (L×W×H) | 4,000 mm × 2,200 mm × 2,300 mm |

| Machine Weight | Approximately 7,200 kg |

| Control System | FANUC or Siemens |

| Automation | Compatible with Robobox XL |

A: Industries such as automotive, aerospace, medical, and general manufacturing benefit from their high-speed, precision, and efficiency.

A: They enable simultaneous machining operations, reducing cycle times and increasing output without compromising accuracy.

A: Yes, these lathes are designed to handle intricate geometries with high precision, making them ideal for demanding applications.

A: They accommodate a wide range of materials, including aluminum, steel, titanium, and high-performance alloys.

A: Yes, they offer various configurations and automation options to meet specific production requirements.