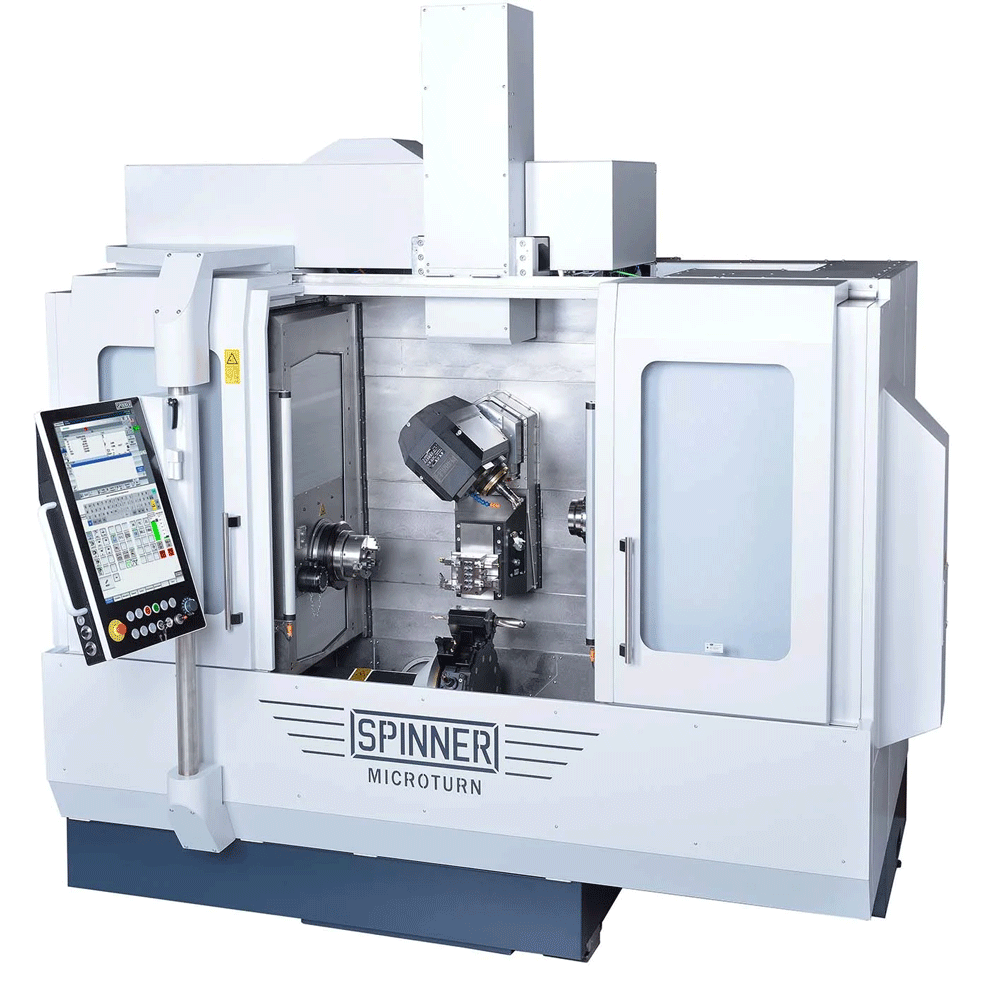

Spinner CNC’s Mill Turn Series offers compact vertical machines that combine submicron precision turning with full 5-axis machining capabilities. Designed for flexibility and rigidity, these machines excel in various part applications while maintaining a small footprint.

Mill turn machines integrate milling and turning operations into a single setup, enhancing efficiency and precision in manufacturing. This combination allows for complex geometries to be machined without multiple setups, reducing production time and potential errors. In industries where precision and efficiency are paramount, such as aerospace and medical device manufacturing, mill turn machines have become indispensable. Their ability to perform multiple operations streamlines workflows and improves overall productivity.

The Mill Turn Series by Spinner CNC boasts a compact vertical design that enhances chip management and saves valuable floor space. These machines are capable of hard turning materials up to 60 HRC, ensuring versatility in material handling. Equipped with gang tooling, they achieve submicron part tolerances, meeting stringent precision requirements. The series also offers plug-and-play automation, facilitating seamless integration into automated production lines for lights-out manufacturing.

Choosing the Mill Turn Series means investing in machines that deliver precision and efficiency. Their compact design optimizes workspace, while the integration of multiple machining capabilities reduces setup times and potential errors. This leads to faster production cycles and cost savings. The ability to handle hard materials and maintain tight tolerances ensures that manufacturers can meet diverse and demanding production requirements with confidence.

Click the dropdowns below to view detailed specifications for the Mill Turn Series.

| MicroTurn LTBS Mill Turn Specifications | |

|---|---|

| Machine Type | Compact Vertical Mill Turn |

| Turning Diameter | Up to 100 mm |

| Turning Length | Up to 200 mm |

| Spindle Speed | Up to 6,000 rpm |

| Spindle Motor Power | 5.5 kW |

| Tool Turret | 8-station turret with driven tools |

| Y-Axis Travel | ±40 mm |

| Sub-Spindle | Optional |

| Control System | Siemens 840D sl |

| Machine Weight | Approximately 2,500 kg |

| Footprint (L x W x H) | 1,800 mm x 1,500 mm x 2,000 mm |

| MicroTurn Grind Mill Turn Specifications | |

|---|---|

| Machine Type | Compact Vertical Mill Turn with Grinding Capability |

| Turning Diameter | Up to 120 mm |

| Turning Length | Up to 250 mm |

| Spindle Speed | Up to 8,000 rpm |

| Spindle Motor Power | 7.5 kW |

| Tool Turret | 12-station turret with driven tools |

| Y-Axis Travel | ±50 mm |

| Grinding Spindle Speed | Up to 10,000 rpm |

| Grinding Wheel Diameter | Up to 150 mm |

| Control System | Siemens 840D sl |

| Machine Weight | Approximately 3,000 kg |

| Footprint (L x W x H) | 2,000 mm x 1,600 mm x 2,100 mm |

A: The Mill Turn Series is capable of machining a wide range of materials, including hardened materials up to 60 HRC, making it suitable for various industrial applications.

A: The compact vertical design enhances chip management and saves floor space, allowing for a more organized and efficient workspace.

A: Yes, the series offers plug-and-play automation features, facilitating seamless integration into automated production lines for increased productivity.

A: Equipped with gang tooling, the Mill Turn Series achieves submicron part tolerances, ensuring high precision in machining operations.

A: Industries requiring high precision and efficiency, such as aerospace, medical device manufacturing, and automotive sectors, benefit significantly from the capabilities of the Mill Turn Series.