Spinner CNC’s 5-Axis CNC Milling Machines are engineered to complete complex parts in a single setup, enhancing efficiency and precision in your machining operations.

5-axis CNC milling machines represent a significant advancement in the machining industry, enabling the creation of intricate components with high precision. By allowing simultaneous movement along five axes, these machines reduce the need for multiple setups, thereby increasing efficiency and accuracy. This technology is particularly relevant in industries requiring complex geometries and tight tolerances, such as aerospace, automotive, and medical device manufacturing.

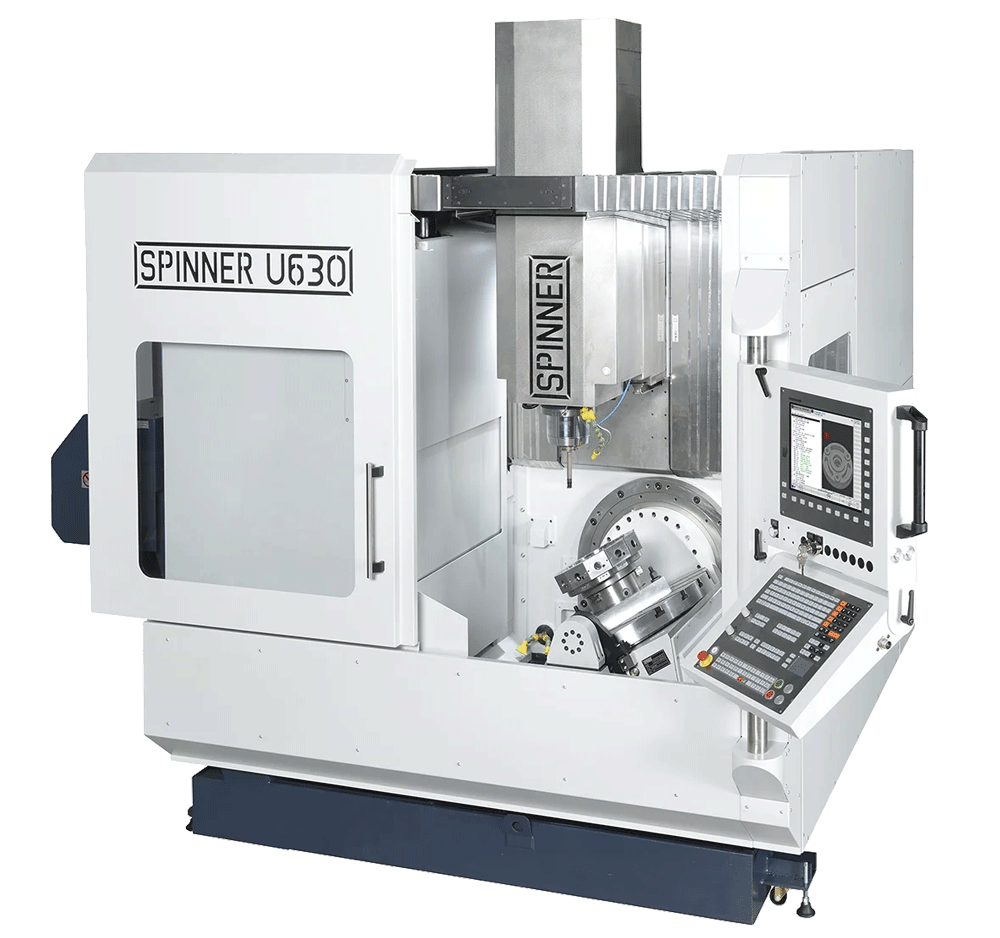

Spinner CNC’s 5-axis machines are designed with a compact footprint, occupying nearly 30% less space compared to similar capacity machines. They are equipped with Heidenhain full 5-axis controls, ensuring smooth and continuous motion. The machines offer expanded tool capacity, accommodating the demands of complex parts. Additionally, they feature a rotary head design that maintains weight over the table, patented guideway covers to keep chips clear, and plug-and-play automation capabilities for enhanced productivity.

Opting for Spinner CNC’s 5-axis machines allows manufacturers to complete complex parts in a single setup, significantly reducing production time and improving precision. The compact design maximizes shop floor space, while the advanced control systems enhance machining accuracy. These features collectively contribute to increased profitability and competitiveness in the market.

Click the dropdowns below to view detailed specifications for the 5-Axis CNC Milling Machines.

| U5-630 Trunnion Specifications | |

|---|---|

| X-axis Travel | 630 mm |

| Y-axis Travel | 530 mm |

| Z-axis Travel | 465 mm |

| Rotary Table Diameter (5th Axis) | 650 mm |

| Spindle Speed | 12,000 – 20,000 rpm |

| Tool Magazine Capacity | 32 – 122 tools |

| Tool Holders | BBT40, HSK63, SK40, BT40 |

| Automation Options | Robobox, Robobox Xtreme |

| Pallet Changer | Available |

| Special Projects | Supported |

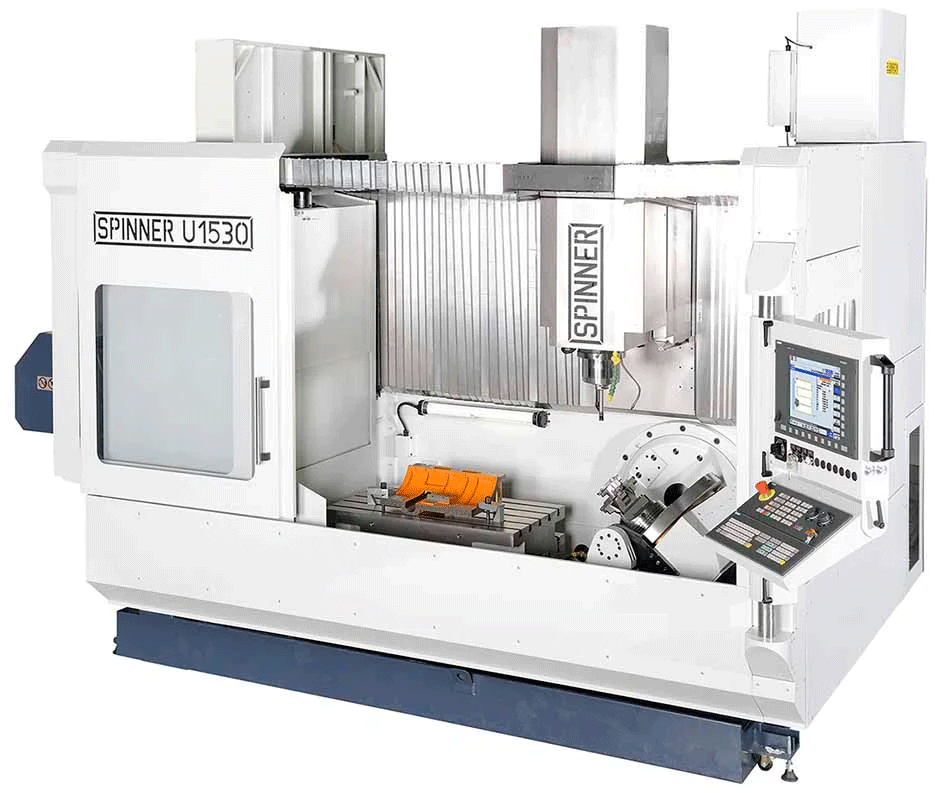

| U5-1530 Trunnion/Fixed Specifications | |

|---|---|

| X-axis Travel | 1,530 mm |

| Y-axis Travel | 530 mm |

| Z-axis Travel | 465 mm |

| Rotary Table Diameter (5th Axis) | 650 mm |

| Additional Fixed Table Size | 920 x 540 mm |

| Spindle Speed | 12,000 – 20,000 rpm |

| Tool Magazine Capacity | 32 – 122 tools |

| Tool Holders | BBT40, HSK63, SK40, BT40 |

| Automation Options | Robobox, Robobox Xtreme |

| Pallet Changer | Available |

| Special Projects | Supported |

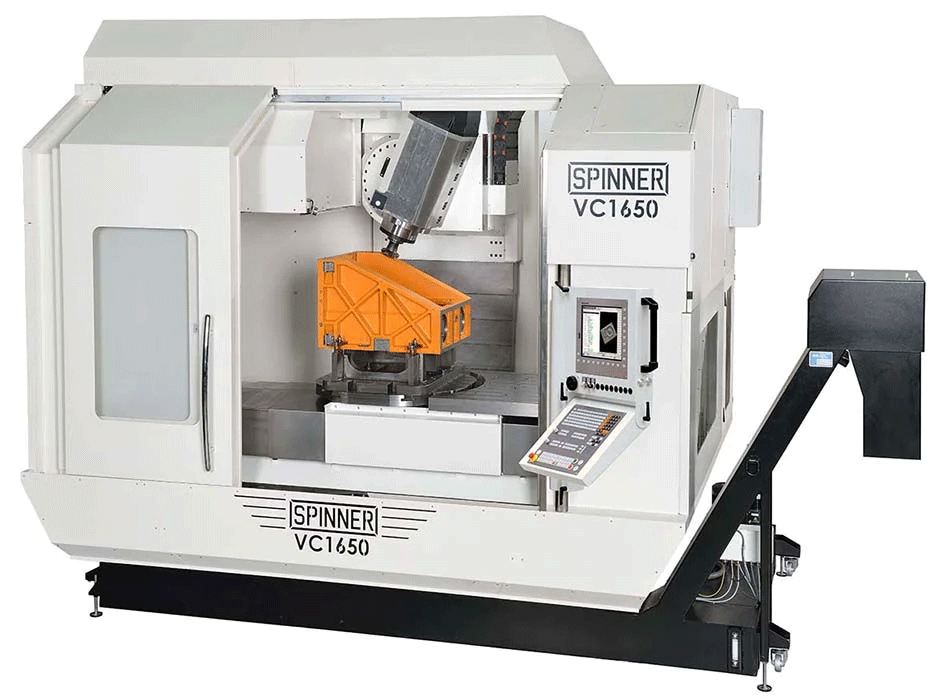

| VC1650-5A Swivel Head Specifications | |

|---|---|

| X-axis Travel | 1,650 mm |

| Y-axis Travel | 820 mm |

| Z-axis Travel | 820 mm |

| Rotary Table Diameter (5th Axis) | 900 mm |

| Spindle Speed | 9,000 – 18,000 rpm |

| Tool Magazine Capacity | 96 – 138 tools |

| Automation Options | Robobox XL |

| Pallet Changer | Available |

| Special Projects | Supported |

| VC850-5A Trunnion Specifications | |

|---|---|

| X-axis Travel | 815 mm |

| Y-axis Travel | 510 mm |

| Z-axis Travel | 510 mm |

| Rotary Table Diameter (5th Axis) | 350 mm |

| Spindle Speed | 12,000 – 18,000 rpm |

| Tool Magazine Capacity | 32 – 48 tools |

| Automation Options | Robobox, Robobox Xtreme |

| Pallet Changer | Available |

| Special Projects | Supported |

A: Spinner CNC offers trunnion, rotary head, and hybrid styles in their 5-axis machining centers, providing flexibility to meet various application needs.

A: The compact design occupies nearly 30% less space than similar capacity machines, optimizing your shop floor layout and allowing for additional equipment or workspace.

A: Spinner CNC’s 5-axis machines are equipped with Heidenhain full 5-axis controls, ensuring smooth and continuous motion for precise machining operations.

A: Yes, the machines are designed with plug-and-play automation capabilities, facilitating seamless integration into automated production lines.

A: Industries requiring complex geometries and tight tolerances, such as aerospace, automotive, and medical device manufacturing, benefit significantly from Spinner CNC’s 5-axis machines.