Spinner CNC’s 3-Axis Vertical Machining Centers are designed for precision, accessibility, and a compact footprint, offering flexible solutions for diverse machining needs.

3-Axis Vertical Machining Centers are essential in modern manufacturing, enabling precise milling operations on various materials. Their vertical orientation allows for efficient chip removal and easy access to the workpiece, enhancing productivity. These machines are vital in industries requiring accurate and repeatable machining processes, contributing significantly to operational efficiency and product quality.

Spinner CNC’s 3-Axis Vertical Machining Centers offer a compact design with a footprint nearly 30% smaller than similar capacity machines. They feature modern controls from Fanuc, Siemens, or Heidenhain, and provide easy access with work tables closer to the front doors. Additional features include large weight capacity options, patented single wiper guideway covers to keep chips clear, and plug-in-play automation readiness for enhanced productivity.

Choosing 3-Axis Vertical Machining Centers enhances manufacturing efficiency through precise and repeatable operations. Their compact design optimizes floor space, while modern controls ensure user-friendly operation. Easy access to the work table facilitates quicker setups and adjustments, reducing downtime. These features collectively lead to increased productivity and profitability in machining operations.

Click the dropdowns below to view detailed specifications for the 3-Axis Vertical Machining Centers.

| VC750 Compact Specifications | |

|---|---|

| X-Axis Travel | 760 mm |

| Y-Axis Travel | 460 mm |

| Z-Axis Travel | 460 mm |

| Spindle Speed | 12,000 rpm |

| Tool Magazine Capacity | 24 – 32 tools |

| Automation Options | Robobox |

| Tool Holders | SK40, BT40 |

| Machine Footprint (W x D x H) | 1,850 x 1,800 x 2,420 mm |

| Machine Weight | 4,500 kg |

| Control Systems | Siemens, Fanuc, Heidenhain |

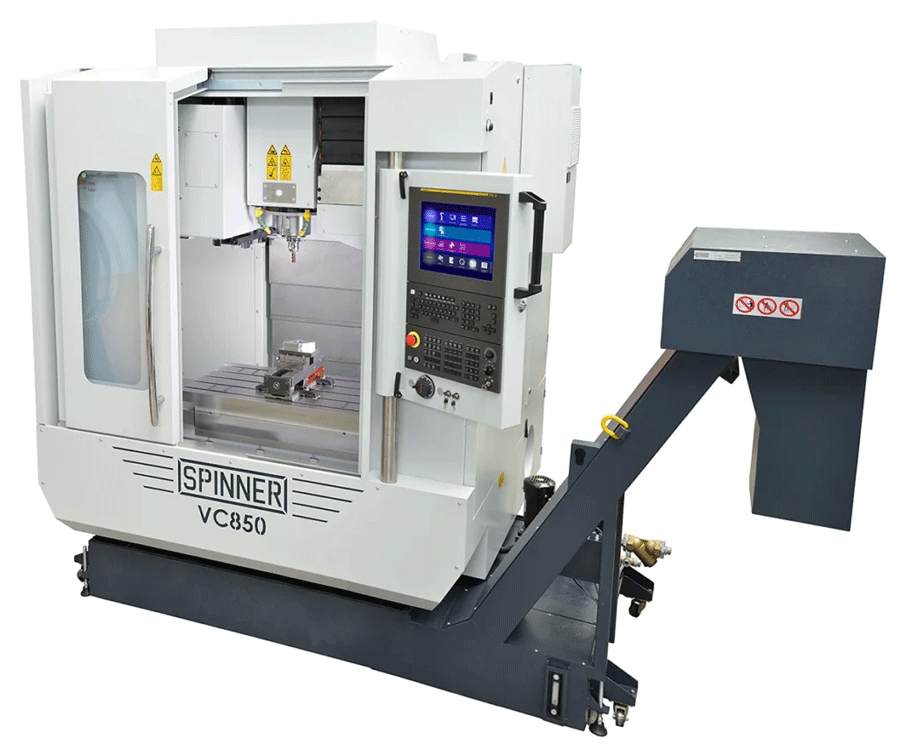

| VC850 Mid Specifications | |

|---|---|

| X-Axis Travel | 850 mm |

| Y-Axis Travel | 510 mm |

| Z-Axis Travel | 510 mm |

| Spindle Speed | 12,000 – 18,000 rpm |

| Tool Magazine Capacity | 32 – 48 tools |

| Automation Options | Robobox, Robobox Xtreme |

| Special Projects Capability | Yes |

| Machine Footprint (W x D x H) | 1,850 x 1,800 x 2,420 mm |

| Machine Weight | 4,500 kg |

| Control Systems | Siemens, Fanuc, Heidenhain |

| VC1150 Mid Specifications | |

|---|---|

| X-Axis Travel | 1,150 mm |

| Y-Axis Travel | 620 mm |

| Z-Axis Travel | 600 mm |

| Spindle Speed | 5,000 – 18,000 rpm |

| Tool Magazine Capacity | 32 – 60 tools |

| Automation Options | Robobox, Robobox Xtreme |

| Special Projects Capability | Yes |

| Tool Holders | HSK63, SK40, BT40, BBT40 |

| Machine Footprint (W x D x H) | 2,750 x 2,530 x 2,810 mm |

| Machine Weight | 10,500 kg |

| Control Systems | Siemens, Fanuc, Heidenhain |

| VC1650 Large Specifications | |

|---|---|

| X-Axis Travel | 1,650 mm |

| Y-Axis Travel | 820 mm |

| Z-Axis Travel | 820 mm |

| Spindle Speed | 9,000 – 18,000 rpm |

| Tool Magazine Capacity | 96 – 138 tools |

| Automation Options | Robobox XL |

| Pallet Changer | Available |

| Tool Holders | HSK100, SK50, BT50, SK40, BT40, HSK63 |

| Machine Footprint (L x W x H) | 3,550 x 2,750 x 3,200 mm |

| Machine Weight | Approximately 16,000 kg |

| Control Systems | Siemens 840D SolutionLine, Heidenhain TNC640 |

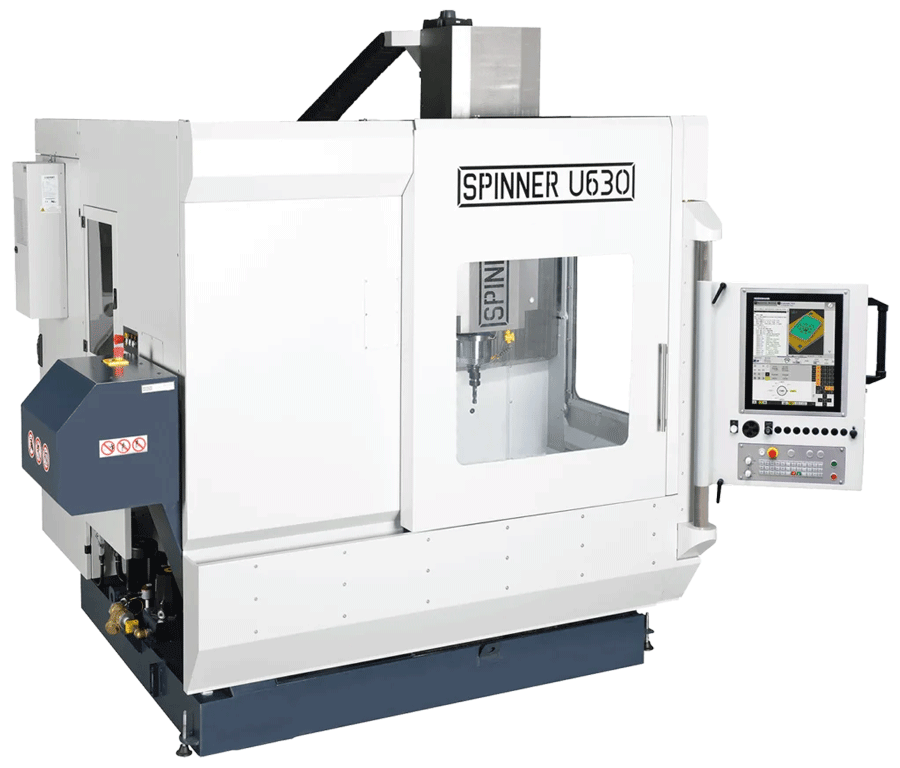

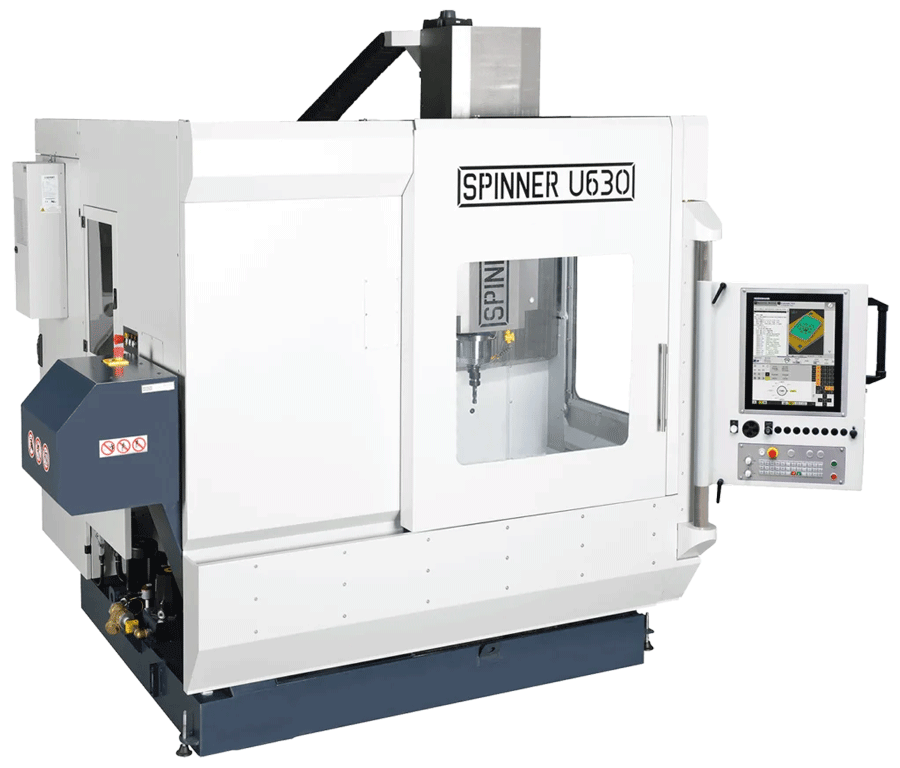

| U3-630 Traveling Column Specifications | |

|---|---|

| X-Axis Travel | 630 mm |

| Y-Axis Travel | 530 mm |

| Z-Axis Travel | 465 mm |

| Table Dimensions (L x W) | 920 x 540 mm |

| Max. Table Load | 750 kg |

| Spindle Speed | 12,000 – 20,000 rpm |

| Tool Magazine Capacity | 24 – 54 tools |

| Feed/Rapid Traverse | 30 m/min |

| Tool Holders | SK40, HSK63 |

| Machine Dimensions (L x W x H) | 2,750 x 2,530 x 2,810 mm |

| Machine Weight | Approximately 8,000 kg |

| Control Systems | Siemens 840D SolutionLine |

| U3-1530 Traveling Column Specifications | |

|---|---|

| X-Axis Travel | 1,530 mm |

| Y-Axis Travel | 530 mm |

| Z-Axis Travel | 465 mm |

| Table Dimensions (L x W) | 1,800 x 540 mm |

| Max. Table Load | 1,500 kg |

| Spindle Speed | 12,000 – 20,000 rpm |

| Tool Magazine Capacity | 32 – 122 tools |

| Feed/Rapid Traverse | 30 m/min |

| Tool Holders | SK40, HSK63 |

| Machine Dimensions (L x W x H) | 4,150 x 2,530 x 2,810 mm |

| Machine Weight | Approximately 12,000 kg |

| Control Systems | Siemens 840D SolutionLine |

A: They offer modern controls from Fanuc, Siemens, or Heidenhain.

A: The compact design occupies nearly 30% less space than similar machines, optimizing your workspace.

A: Yes, they are designed with plug-in-play automation readiness for enhanced productivity.

A: They offer large weight capacity options, suitable for various part sizes.

A: The single wiper design keeps chips clear, ensuring smoother operation and reduced maintenance.