Quick Die Change System from Kosmek streamlines die-changing operations in manufacturing, boosting efficiency and minimizing downtime. Designed for precision and reliability, it enhances productivity across industries.

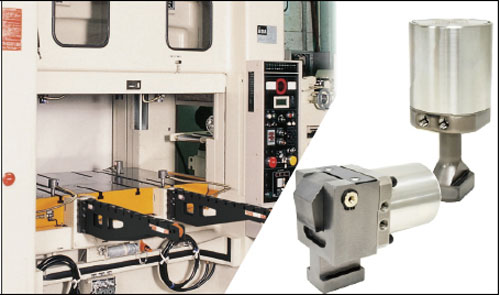

Kosmek’s Quick Die Change System (QDCS) redefines efficiency in die change operations. Used extensively in manufacturing industries, it minimizes downtime and improves production flow. Its state-of-the-art design ensures seamless compatibility with various equipment, offering a robust solution for rapid die switching. With a focus on safety and performance, QDCS exemplifies Kosmek’s commitment to innovative manufacturing technologies.

Kosmek’s Quick Die Change System delivers unmatched speed and accuracy. Featuring advanced clamping units, precision alignment mechanisms, and compact designs, it suits diverse press systems. Automated controls further optimize operations, reducing manual intervention. This efficient design increases throughput, minimizes errors, and ensures operator safety.

Kosmek’s QDCS reduces setup times, boosts production rates, and enhances operational safety. Its streamlined design ensures precise die positioning, decreasing error rates. These systems also lower labor costs, enabling manufacturers to optimize resources effectively while maintaining high-quality standards.

Click the dropdowns below to view detailed information for each model in the Quick Die Change System

Series.

| GA Clamp T-Slot Manual Slide Model GA | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Varies by model |

| Features | Slides in the T-slot and locks in the U-cut of the die; compact single-action cylinder; space-efficient mounting; variety of options available |

| GD Clamp T-Slot Automatic Slide Model GD | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Varies by model |

| Features | GA clamp with an air cylinder; suitable for inaccessible areas or non-operation side; fully automated clamp movement |

| GBB Clamp T-Slot Manual-Slide (Single Action) Model GBB | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Varies by model |

| Features | Lever clamp that slides in the T-slot by hand; suitable for non-standardized die widths |

| GBC Clamp T-Slot Manual-Slide/Longer Stroke (Single Action) Model GBC | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Longer stroke to accommodate variations in die clamping thicknesses |

| Features | Lever clamp that slides in the T-slot by hand; suitable for non-standardized die widths; longer stroke allows for variation in die clamping thicknesses |

| GBE Clamp T-slot Automatic-Slide (Single Action) Model GBE | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Varies by model |

| Features | GBB clamp with an air cylinder; slides in the T-slot and locks the die automatically by remote control |

| GBF Clamp Longer Stroke/T-Slot Automatic-Slide (Single Action) Model GBF | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Longer stroke to accommodate variations in die clamping thicknesses |

| Features | GBC clamp with an air cylinder; slides in the T-slot and locks the die automatically by remote control; longer stroke allows for variation in die clamping thicknesses |

| GBP Clamp Block-Fixed (Single Action) Model GBP | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Compact stroke suitable for fixed positions |

| Features | Compact block-fixed design; suitable for standardized die widths; lever operation for simple manual clamping |

| GPC Clamp Block-Fixed (Automatic Single Action) Model GPC | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Compact stroke with automatic operation |

| Features | Fixed position block clamp with air cylinder for automated clamping; suitable for standardized die widths |

| GBQ Clamp Block-Fixed (Single Action/Longer Stroke) Model GBQ | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Extended stroke for variable die clamping thicknesses |

| Features | Longer stroke fixed block clamp; lever operation for manual clamping; suitable for wider die variations |

| GPE Clamp Block-Fixed (Automatic/Longer Stroke) Model GPE | |

|---|---|

| Clamping Force | Varies by model |

| Applicable Die Thickness | Varies by model |

| Stroke | Extended stroke with automatic operation |

| Features | Automatic block-fixed clamp with air cylinder; accommodates a wide range of die thicknesses; efficient for high-volume applications |

A: It significantly reduces die change time, boosting productivity and efficiency in manufacturing.

A: Yes, Kosmek’s QDCS is designed for compatibility with a wide range of press machines and equipment.

A: The system features secure clamping mechanisms and automated operations, reducing manual intervention and enhancing operator safety.

A: Absolutely. Kosmek’s QDCS is engineered for durability and efficiency, making it ideal for high-volume manufacturing operations.

A: Industries like automotive, appliance manufacturing, and metalworking extensively use Kosmek’s Quick Die Change System to enhance production efficiency.