Piovan UnaDyn’s Dosing & Blending systems deliver precise material dosing and uniform blending, ensuring consistent quality, reduced waste, and enhanced efficiency in plastic manufacturing processes.

Dosing and blending are critical processes in the plastics industry, ensuring precise measurement and homogeneous mixing of materials for consistent product quality. Piovan UnaDyn offers a comprehensive range of volumetric and gravimetric dosing units and blenders, including the Quantum series, designed to handle various materials and production requirements. These solutions enhance efficiency and accuracy in plastic manufacturing operations.

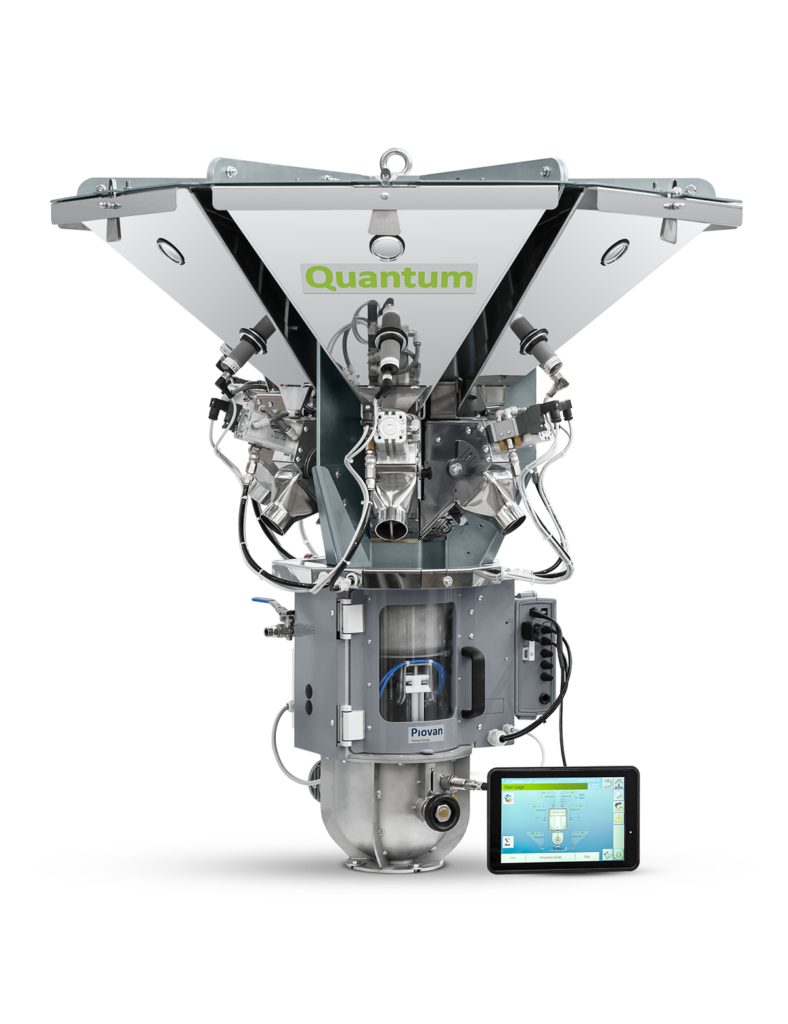

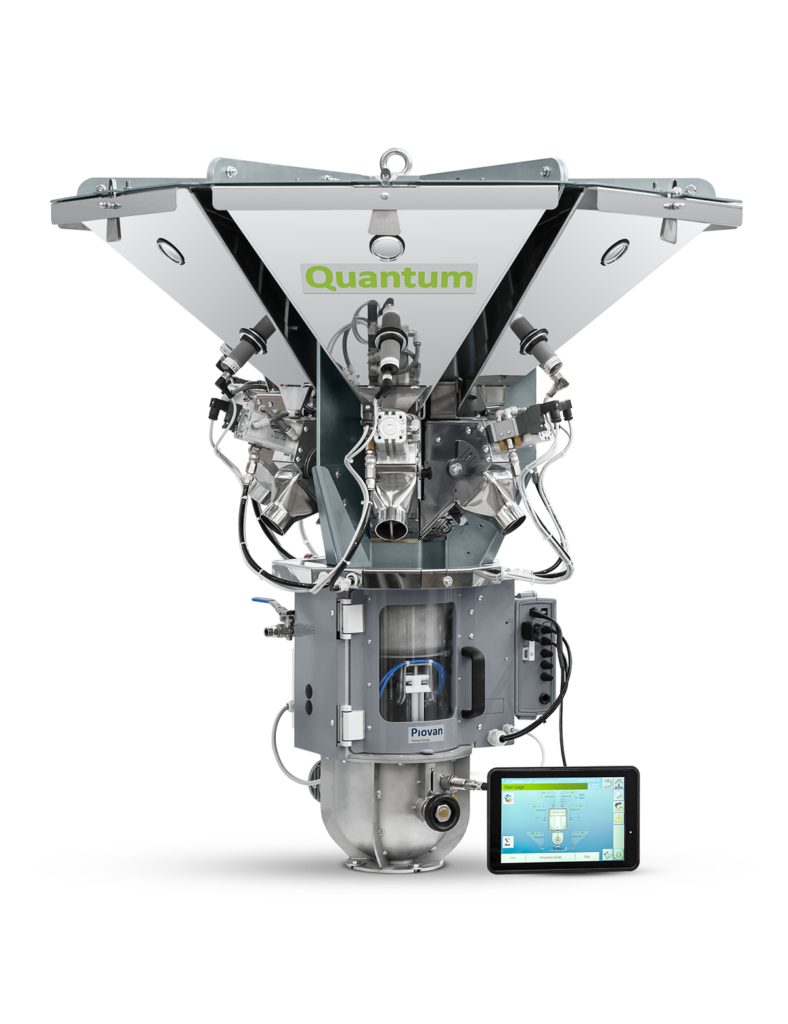

Piovan UnaDyn’s dosing and blending systems, such as the Quantum series, feature high dosing precision and accuracy, quick material change capabilities, and simplified cleaning operations. The redesigned mixing shafts ensure better homogenization of batches, while the semi-spherical shape prevents material stagnation. These systems are suitable for various materials, including granules, additives, and powders, and can handle throughputs up to 3,968 lbs/hr, accommodating diverse production needs.

Selecting Piovan UnaDyn’s dosing and blending solutions ensures precise material dosing and uniform blending, leading to consistent product quality and reduced material waste. The advanced design facilitates quick material changes and easy cleaning, minimizing downtime and enhancing operational efficiency. These systems are adaptable to various production scales and materials, providing flexibility and scalability for manufacturers.

Click the dropdowns below to view detailed information for each model in the Dosing & Blending Series.

Ensures high dosing precision and quick material changes with simplified cleaning. Designed for throughputs up to 3,968 lbs/hr for consistent and accurate blending.

Suitable for granules, additives, and powders with precise control over extrusion lines. Operates efficiently in both overfeed and underfeed modes.

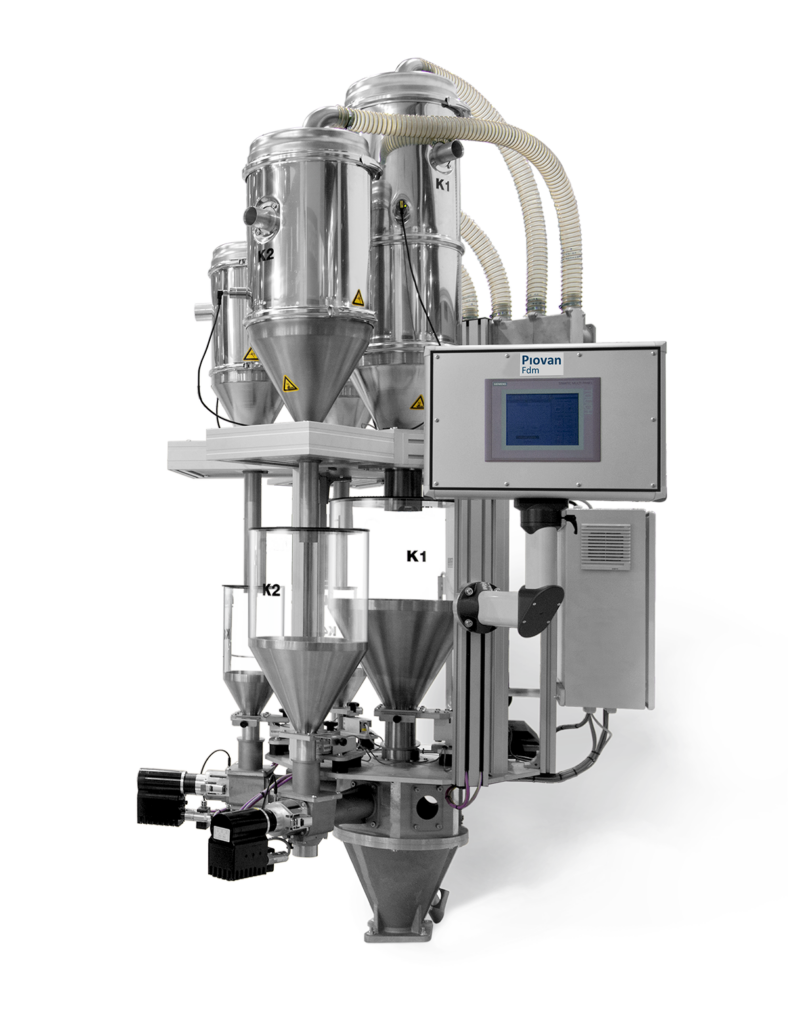

Handles throughputs up to 3,000 kg/h, offering quick material changes, simplified cleaning, and compatibility with flakes and high-temperature materials.

Delivers accurate dosing from 5 g/h to 150 kg/h with sloping screw geometry and a central block design for smooth flow and easy cleaning.

Provides highly accurate dosing from 0.21 to 190 kg/h. Features user-friendly controls, touch-screen interface, and compatibility with low-melting additives.

Designed for granules, flakes, and powders, ensuring precise dosing and complete control of extrusion lines for efficient material blending.

Optimized for continuous extrusion control with single or co-extrusion lines, ensuring maximum accuracy and easy maintenance with quick hopper access.

Offers high accuracy at low dosing rates with modular flexibility, accommodating 2 to 6 components for uniform mixing and seamless control.

A: They are designed to process a wide range of materials, including granules, additives, powders, and regrind, accommodating diverse production requirements.

A:The systems utilize advanced technologies, such as gravimetric and volumetric dosing mechanisms, to achieve high precision and repeatability in material dosing.

A: Yes, they are designed for quick material changes and simplified cleaning operations, reducing downtime and maintenance efforts.

A: Piovan UnaDyn’s dosing and blending solutions are designed for easy integration into various production setups, enhancing flexibility and scalability.

A: The systems can handle a wide range of throughput capacities, with certain models, like the Quantum series, accommodating up to 3,968 lbs/hr, suitable for different production scales.