Harvard Factory Automation’s Parts Conditioning systems deliver precision in part handling processes like cooling, heating, drying, and cleaning. These solutions streamline manufacturing operations, ensuring quality and reliability for various industries. Engineered with innovation, they enhance productivity.

Parts Conditioning systems are vital in modern manufacturing, providing effective cooling, heating, drying, and cleaning for components. These solutions ensure consistent quality, precision, and reliability in production lines. With advanced technology and seamless integration, they are a cornerstone for efficiency in high-demand industries.

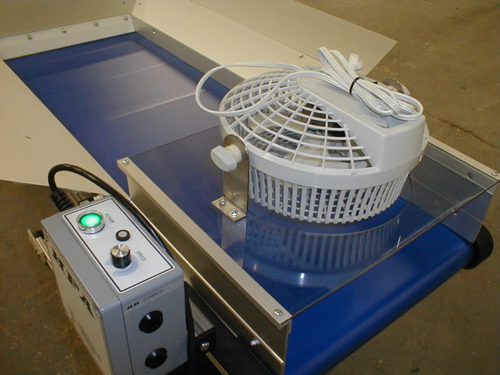

Harvard Factory Automation’s Parts Conditioning systems feature advanced cooling and heating mechanisms, precise airflow control, and customizable options to fit various needs. Their compact design supports easy integration, while energy efficiency minimizes costs. Durable materials ensure long-lasting performance in demanding manufacturing environments.

These systems improve product quality, reduce operational inefficiencies, and enhance consistency in manufacturing processes. Their robust and innovative design minimizes downtime, delivering excellent value for businesses aiming for reliable, top-tier part conditioning solutions.

Click the dropdowns below to view detailed information for each model in the Parts Conditioning Series.

| Water Chiller Unit Specifications | |

|---|---|

| Application | Designed for integration with 2230 conveyor systems and other industrial setups requiring cooling solutions. |

| Cooling Capacity | Up to 10,000 BTU/hour, suitable for various industrial cooling requirements. |

| Temperature Range | Adjustable range from 40°F to 80°F (4°C to 27°C) for precise cooling control. |

| Dimensions | 24″ L x 18″ W x 36″ H (610 mm x 457 mm x 914 mm). |

| Weight | Approximately 150 lbs (68 kg). |

| Housing | Durable blue powder-coated steel housing for long-lasting performance and aesthetic appeal. |

| Portability | Equipped with swivel casters and locking brakes for easy positioning and stability. |

| Pump Type | High-performance centrifugal pump for consistent water flow. |

| Reservoir Capacity | 5-gallon (19-liter) insulated tank for extended operation. |

| Control System | Digital thermostat with an LED display for easy monitoring and adjustments. |

| Power Supply | 120V AC, 60Hz, 15A with a standard NEMA 5-15 plug. |

| Energy Efficiency | Eco-friendly design with optimized energy consumption. |

| Noise Level | Less than 65 dB(A) for quiet operation. |

| Integration | Seamlessly integrates with Harvard Factory Automation’s 2230 conveyor systems and other compatible equipment. |

| Maintenance | Easy-access panels for quick servicing and routine maintenance. |

| Warranty | 1-year limited warranty covering parts and labor. |

A: Parts Conditioning involves cooling, heating, drying, or cleaning parts during manufacturing to enhance quality and efficiency.

A: Their systems offer reliable, customizable, and energy-efficient solutions tailored to diverse manufacturing needs.

A: Industries like automotive, electronics, and medical devices benefit from these solutions for consistent part quality.

A: Yes, Harvard Factory Automation provides tailored solutions to fit specific manufacturing requirements.

A: Regular cleaning and inspections ensure peak performance. Their durable design minimizes the need for extensive maintenance.