The TWX-RIII Series from Nissei offers advanced mold clamping, exceptional precision, energy efficiency, enhanced safety, and cost-effective options, perfect for maximizing injection molding performance.

The TWX-RⅢ Series by Nissei represents a line of vertical hybrid injection molding machines with clamping forces ranging from 220 to 300 tons. Developed from the successful TNX Series, these machines feature a new compound clamping mechanism and a super low-profile structure, enhancing safety and usability. They are ideal for insert molding applications across various industries, offering improved operational efficiency and reduced costs.

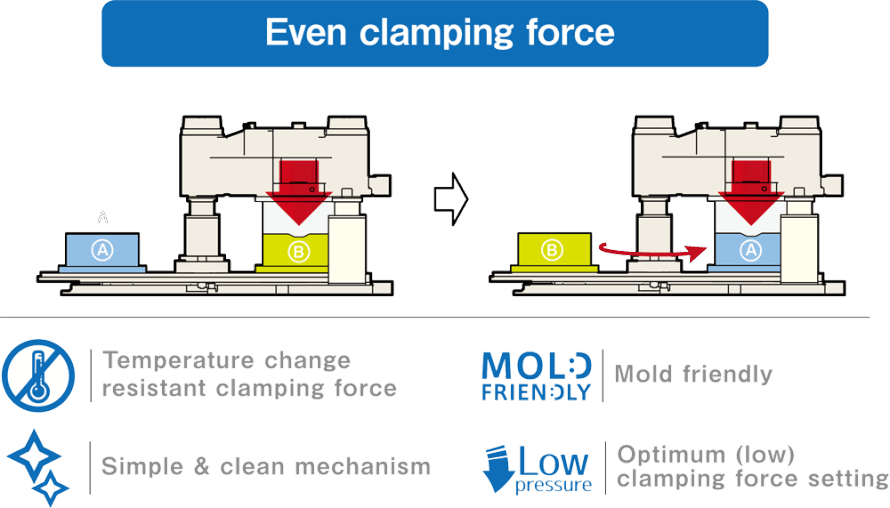

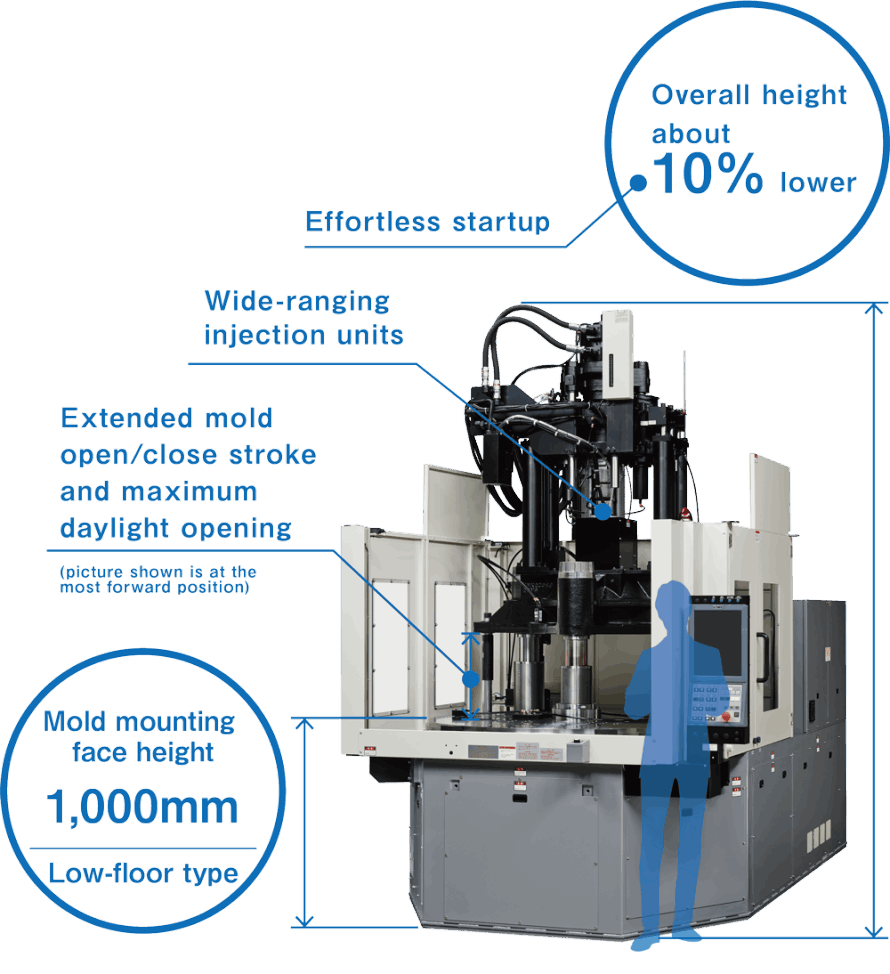

Key features of the TWX-RⅢ Series include a direct-pressure clamping mechanism that evenly transmits clamping force to the mold, ensuring consistent performance regardless of temperature changes. The machines boast a low-profile design with mold mounting faces at 1,000mm, facilitating easier mold installation and product removal. An optimized bed structure allows flexible robot integration, and the series accommodates larger, more complex molds with wider open/close strokes and maximum daylight openings.

Choosing the TWX-RⅢ Series provides manufacturers with enhanced usability, leading to increased productivity and reduced ancillary equipment costs. The direct-pressure clamping mechanism maintains long-term machine precision, while the low-profile design improves safety and ergonomics. These features make the TWX-RⅢ Series a valuable asset for efficient and reliable insert molding operations.

Click the dropdowns below to view detailed specifications for each model in the TWX-RIII Series.

| Item | Unit | 25V (Turntable) |

|---|---|---|

| Screw Diameter | inch (mm) | 1.57 (40), 1.77 (45), 1.97 (50) |

| Injection Capacity | inch³ (cm³) (oz) | 12.3 (201) (6.7), 15.5 (254) (8.5), 19.2 (314) (10.5) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 32,210 (222) (2270), 25,390 (175) (1790), 20,610 (142) (1450) |

| Clamping Force | USton (kN) (tf) | 242 (2156) (220) |

| Clamping Stroke | inch (mm) | 12.6 |

| Min. Mold Thickness | inch (mm) | 13.8 |

| Max. Daylight Opening | inch (mm) | 32.3 (820) |

| Die Plate Dimensions (H×V) | inch (mm) | 35.4 x 26.4 (900 x 670) |

| Ejector Stroke | inch (mm) | 3.1 (80) |

| Item | Unit | 36V (Turntable) |

|---|---|---|

| Screw Diameter | inch (mm) | 1.77 (45), 1.97 (50), 2.20 (56) |

| Injection Capacity | inch³ (cm³) (oz) | 17.5 (286) (9.6), 21.5 (353) (11.8), 27.0 (443) (14.8) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 32,360 (223) (2280), 26,270 (181) (1850), 20,900 (144) (1470) |

| Clamping Force | USton (kN) (tf) | 330 (2942) (300) |

| Clamping Stroke | inch (mm) | 11.8 |

| Min. Mold Thickness | inch (mm) | 17.7 |

| Max. Daylight Opening | inch (mm) | 36.2 (920) |

| Die Plate Dimensions (H×V) | inch (mm) | 40.6 x 30.2 (1030 x 768) |

| Ejector Stroke | inch (mm) | 4.9 (125) |

A: The series offers clamping forces ranging from 220 to 300 tons, suitable for various molding requirements.

A:It ensures even transmission of clamping force to the mold, providing consistent performance and maintaining machine precision over time.

A: With mold mounting faces at 1,000mm, the design facilitates easier mold installation, setup, and product removal, enhancing overall usability.

A: Yes, the machines feature wider mold open/close strokes and maximum daylight openings, supporting larger and more complex molds.

A: Absolutely, the optimized bed structure permits flexible robot layout, enabling seamless integration of automation systems for improved efficiency.