The NEX-V Series from Nissei offers enhanced injection speed, energy-saving performance, advanced control systems, and precision molding, making it perfect for efficient, high-quality production.

The NEX-V Series by Nissei represents the latest advancement in all-electric injection molding technology, offering clamping forces ranging from 30 to 360 tons (33 to 397 U.S. tons). Designed to enhance precision and efficiency, these machines cater to diverse manufacturing sectors, including automotive, medical devices, and consumer goods. The NEX-V Series builds upon its predecessors’ success, incorporating innovative features to meet evolving industry demands.

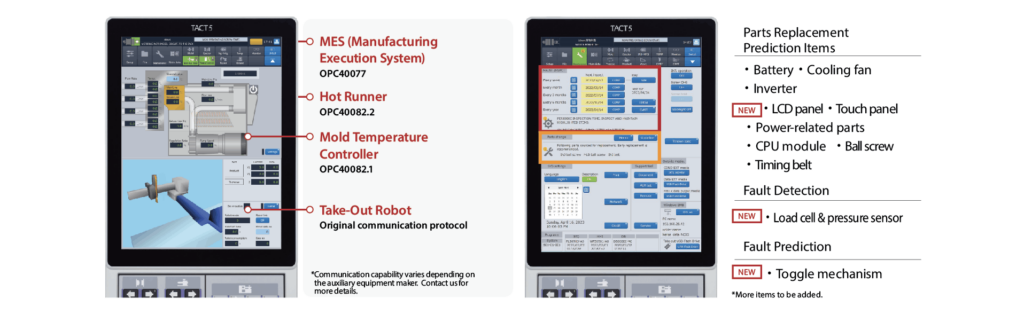

Key features of the NEX-V Series include the new IoT-enabled “TACT5” controller, which facilitates real-time data collection, remote monitoring, and maintenance, aligning with Industry 4.0 standards. The series complies with the universal safety standard ISO20430, ensuring enhanced operational safety. Additionally, a newly designed standard screw improves plasticization, leading to better molten resin quality and overall product integrity.

Choosing the NEX-V Series offers substantial benefits, such as improved mold open/close precision and repeatability, which enhance production efficiency. The machines provide uniform clamping force transmission, reducing wear and extending mold life. Energy-efficient operation and excellent maintainability contribute to lower operational costs and minimal downtime, making the NEX-V Series a cost-effective solution for manufacturers seeking high performance and reliability.

Click the dropdowns below to view detailed specifications for each model in the NEX-V Series.

| Item | Unit | 2E | 3E |

|---|---|---|---|

| Screw Diameter | inch (mm) | A: 0.63 (16), B: 0.75 (19) | A: 0.75 (19), B: 0.87 (22) |

| Injection Capacity | inch³ (cm³) (oz) | 0.8 (13) (0.4), 1.1 (18) (0.6) | 1.4 (23) (0.8), 2.1 (35) (1.2) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 38,450 (265) (2704), 28,440 (196) (2000) | 38,450 (265) (2704), 30,470 (210) (2143) |

| Clamping Force | USton (kN) (tf) | 33 (294) (30) | Same as 2E |

| Clamping Stroke | inch (mm) | 9.06 (230) | Same as 2E |

| Mold Thickness (min-max) | inch (mm) | 5.91 | Same as 2E |

| Max. Daylight Opening | inch (mm) | 23.8 (605) | Same as 2E |

| Tie Bar Clearance (H×V) | inch (mm) | 12.2 x 12.2 (310 x 310) | Same as 2E |

| Die Plate Dimensions (H×V) | inch (mm) | 17.7 x 17.7 (450 x 450) | Same as 2E |

| Ejector Stroke | inch (mm) | 1.97 (50) | Same as 2E |

| Item | Unit | 3E | 5E |

|---|---|---|---|

| Screw Diameter | inch (mm) | A: 0.75 (19), B: 0.87 (22) | A: 0.87 (22), B: 1.02 (26), BB: 1.10 (28) |

| Injection Capacity | inch³ (cm³) (oz) | 1.4 (23) (0.8), 2.1 (35) (1.2) | 2.1 (35) (1.2), 3.0 (49) (1.6), 3.5 (57) (1.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 38,450 (265) (2704), 30,470 (210) (2143) | 40,630 (280) (2857), 28,440 (196) (2000), 24,520 (169) (1725) |

| Clamping Force | USton (kN) (tf) | 55 (490) (50) | Same as 3E |

| Clamping Stroke | inch (mm) | 9.84 (250) | Same as 3E |

| Mold Thickness (min.-max.) | inch (mm) | 5.91 | Same as 3E |

| Max. Daylight Opening | inch (mm) | 28.0 (710) | Same as 3E |

| Tie Bar Clearance (H×V) | inch (mm) | 14.2 x 14.2 (360 x 360) | Same as 3E |

| Die Plate Dimensions (H×V) | inch (mm) | 19.9 x 19.9 (505 x 505) | Same as 3E |

| Ejector Stroke | inch (mm) | 2.95 (75) | Same as 3E |

| Item | Unit | 5E | 9E | 12E |

|---|---|---|---|---|

| Screw Diameter | inch (mm) | A: 0.87 (22), B: 1.02 (26), BB: 1.10 (28) | AA: 1.02 (26), A: 1.10 (28), B: 1.26 (32) | AA: 1.10 (28), A: 1.26 (32), B: 1.42 (36) |

| Injection Capacity | inch³ (cm³) (oz) | 2.1 (35) (1.2), 3.0 (49) (1.6), 3.5 (57) (1.9) | 3.6 (59) (2.0), 4.2 (69) (2.3), 5.5 (90) (3.0) | 4.7 (77) (2.6), 6.2 (101) (3.4), 7.7 (127) (4.3) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40,630 (280) (2857), 28,440 (196) (2000), 24,520 (169) (1725) | 40,630 (280) (2857), 35,260 (243) (2480), 26,990 (186) (1898) | 40,630 (280) (2857), 32,360 (223) (2276), 25,680 (177) (1806) |

| Clamping Force | USton (kN) (tf) | 88 (784) (80) | Same as 5E | Same as 5E |

| Clamping Stroke | inch (mm) | 11.8 (300) | Same as 5E | Same as 5E |

| Mold Thickness (min.-max.) | inch (mm) | 5.91 | Same as 5E | Same as 5E |

| Max. Daylight Opening | inch (mm) | 30.9 (785) | Same as 5E | Same as 5E |

| Tie Bar Clearance (H×V) | inch (mm) | 16.5 x 16.5 (420 x 420) | Same as 5E | Same as 5E |

| Die Plate Dimensions (H×V) | inch (mm) | 22.8 x 22.8 (580 x 580) | Same as 5E | Same as 5E |

| Ejector Stroke | inch (mm) | 2.95 (75) | Same as 5E | Same as 5E |

| Item | Unit | 9E | 12E | 18E |

|---|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.02 (26), A: 1.10 (28), B: 1.26 (32) | AA: 1.10 (28), A: 1.26 (32), B: 1.42 (36) | AA: 1.26 (32), A: 1.42 (36), B: 1.57 (40) |

| Injection Capacity | inch³ (cm³) (oz) | 3.6 (59) (2.0), 4.2 (69) (2.3), 5.5 (90) (3.0) | 4.7 (77) (2.6), 6.2 (101) (3.4), 7.8 (127) (4.3) | 7.1 (117) (3.9), 9.0 (148) (5.0), 11.1 (182) (6.1) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40,630 (280) (2857), 35,260 (243) (2480), 26,990 (186) (1898) | 40,630 (280) (2857), 32,360 (223) (2276), 25,680 (177) (1806) | 40,050 (276) (2816), 31,630 (218) (2225), 25,680 (177) (1806) |

| Clamping Force | USton (kN) (tf) | 121 (1080) (110) | Same as 9E | Same as 9E |

| Clamping Stroke | inch (mm) | 13.8 (350) | Same as 9E | Same as 9E |

| Mold Thickness (min.-max.) | inch (mm) | 7.09 ~ 20.1 (180 ~ 510) | Same as 9E | Same as 9E |

| Max. Daylight Opening | inch (mm) | 33.9 (860) | Same as 9E | Same as 9E |

| Tie Bar Clearance (H×V) | inch (mm) | 18.1 x 18.1 (460 x 460) | Same as 9E | Same as 9E |

| Die Plate Dimensions (H×V) | inch (mm) | 25.5 x 25.5 (647 x 647) | Same as 9E | Same as 9E |

| Ejector Stroke | inch (mm) | 3.94 (100) | Same as 9E | Same as 9E |

| Item | Unit | 12E | 18E | 25E |

|---|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.10 (28), A: 1.26 (32), B: 1.42 (36) | AA: 1.26 (32), A: 1.42 (36), B: 1.57 (40) | AA: 1.42 (36), A: 1.57 (40), B: 1.70 (45) |

| Injection Capacity | inch³ (cm³) (oz) | 4.7 (77) (2.6), 6.2 (101) (3.4), 7.7 (127) (4.3) | 7.1 (117) (3.9), 9.0 (148) (5.0), 11.1 (182) (6.1) | 9.9 (163) (5.5), 12.3 (201) (6.7), 15.5 (254) (8.5) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40,630 (280) (2857), 32,360 (223) (2276), 25,680 (177) (1806) | 40,050 (276) (2816), 31,630 (218) (2225), 25,680 (177) (1806) | 37,870 (261) (2663), 30,620 (211) (2153), 24,230 (167) (1704) |

| Clamping Force | USton (kN) (tf) | 154 (1373) (140) | Same as 12E | Same as 12E |

| Clamping Stroke | inch (mm) | 15.7 (400) | Same as 12E | Same as 12E |

| Mold Thickness (min.-max.) | inch (mm) | 7.09 | Same as 12E | Same as 12E |

| Max. Daylight Opening | inch (mm) | 37.4 (950) | Same as 12E | Same as 12E |

| Tie Bar Clearance (H×V) | inch (mm) | 20.1 x 20.1 (510 x 510) | Same as 12E | Same as 12E |

| Die Plate Dimensions (H×V) | inch (mm) | 28.3 x 28.3 (720 x 720) | Same as 12E | Same as 12E |

| Ejector Stroke | inch (mm) | 4.72 (120) | Same as 12E | Same as 12E |

| Item | Unit | 18E | 25E | 36E |

|---|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.26 (32), A: 1.42 (36), B: 1.57 (40) | AA: 1.42 (36), A: 1.57 (40), B: 1.77 (45) | AA: 1.57 (40), A: 1.77 (45), B: 1.97 (50) |

| Injection Capacity | inch³ (cm³) (oz) | 7.1 (117) (3.9), 9.0 (148) (5.0), 11.1 (182) (6.1) | 9.95 (163) (5.5), 12.3 (201) (6.7), 15.5 (254) (8.5) | 13.8 (226) (7.6), 17.5 (286) (9.6), 21.5 (353) (11.8) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 40,050 (276) (2816), 31,620 (218) (2224), 25,680 (177) (1806) | 37,870 (261) (2663), 30,620 (211) (2153), 24,230 (167) (1704) | 37,730 (260) (2653), 29,890 (206) (2102), 24,230 (167) (1704) |

| Clamping Force | USton (kN) (tf) | 198 (1765) (180) | Same as 18E | Same as 18E |

| Clamping Stroke | inch (mm) | 17.7 (450) | Same as 18E | Same as 18E |

| Mold Thickness (min.-max.) | inch (mm) | 6.89 | Same as 18E | Same as 18E |

| Max. Daylight Opening | inch (mm) | 40.7 (1035) | Same as 18E | Same as 18E |

| Tie Bar Clearance (H×V) | inch (mm) | 22.0 x 22.0 (560 x 560) | Same as 18E | Same as 18E |

| Die Plate Dimensions (H×V) | inch (mm) | 31.5 x 31.5 (800 x 800) | Same as 18E | Same as 18E |

| Ejector Stroke | inch (mm) | 5.91 (150) | Same as 18E | Same as 18E |

| Item | Unit | 50E | 71E |

|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.77 (45), A: 1.97 (50), B: 2.20 (56) | AA: 1.97 (50), A: 2.20 (56), B: 2.48 (63) |

| Injection Capacity | inch³ (cm³) (oz) | 19.9 (326) (10.9), 24.6 (403) (13.5), 30.8 (505) (16.9) | 27.0 (442) (14.8), 33.8 (554) (18.6), 42.8 (701) (23.5) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36,280 (250) (2551), 29,310 (202) (2061), 23,360 (161) (1643) | 36,130 (249) (2541), 28,880 (199) (2031), 22,780 (157) (1602) |

| Clamping Force | USton (kN) (tf) | 243 (2160) (220) | Same as 50E |

| Clamping Stroke | inch (mm) | 21.7 (550) | Same as 50E |

| Mold Thickness (min.-max.) | inch (mm) | 10.8 | Same as 50E |

| Max. Daylight Opening | inch (mm) | 48.4 (1230) | Same as 50E |

| Tie Bar Clearance (H×V) | inch (mm) | 26.0 x 24.0 (660 x 610) | Same as 50E |

| Die Plate Dimensions (H×V) | inch (mm) | 36.2 x 34.3 (920 x 870) | Same as 50E |

| Ejector Stroke | inch (mm) | 5.91 (150) | Same as 50E |

| Item | Unit | 71E | 100LE |

|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.97 (50), A: 2.20 (56), B: 2.48 (63) | AA: 1.97 (50), A: 2.20 (56), B: 2.48 (63) |

| Injection Capacity | inch³ (cm³) (oz) | 27.0 (442) (14.8), 33.8 (554) (18.6), 42.8 (701) (23.5) | 33.6 (550) (18.4), 47.4 (776) (26.0), 59.9 (982) (32.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36,130 (249) (2541), 28,880 (199) (2031), 22,780 (157) (1602) | 36,130 (249) (2541), 28,880 (199) (2031), 22,780 (157) (1602) |

| Clamping Force | USton (kN) (tf) | 308 (2740) (280) | 397 (3530) (360) |

| Clamping Stroke | inch (mm) | 23.6 (600) | 25.6 (650) |

| Mold Thickness (min.-max.) | inch (mm) | 11.8 | 11.8 |

| Max. Daylight Opening | inch (mm) | 53.1 (1350) | 56.7 (1440) |

| Tie Bar Clearance (H×V) | inch (mm) | 29.9 x 26.0 (760 x 660) | 31.9 x 29.9 (810 x 760) |

| Die Plate Dimensions (H×V) | inch (mm) | 41.5 x 37.6 (1055 x 955) | 44.5 x 42.5 (1130 x 1080) |

| Ejector Stroke | inch (mm) | 5.91 (150) | 7.87 (200) |

| Item | Unit | 100LE |

|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.97 (50), A: 2.20 (56), B: 2.48 (63) |

| Injection Capacity | inch³ (cm³) (oz) | 33.6 (550) (18.4), 47.4 (776) (26.0), 59.9 (982) (32.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36,130 (249) (2541), 28,880 (199) (2031), 22,780 (157) (1602) |

| Clamping Force | USton (kN) (tf) | 397 (3530) (360) |

| Clamping Stroke | inch (mm) | 25.6 (650) |

| Mold Thickness (min.-max.) | inch (mm) | 11.8 x 31.1 (300~790) |

| Max. Daylight Opening | inch (mm) | 56.7 (1440) |

| Tie Bar Clearance (H×V) | inch (mm) | 31.9 x 29.9 (810 x 760) |

| Die Plate Dimensions (H×V) | inch (mm) | 44.5 x 42.5 (1130 x 1080) |

| Ejector Stroke | inch (mm) | 7.87 (200) |

A: The NEX-V Series offers clamping forces ranging from 30 to 360 tons (33 to 397 U.S. tons), accommodating various manufacturing requirements.

A:The IoT-enabled “TACT5” controller allows real-time data collection, remote monitoring, and maintenance, facilitating integration with smart factory systems and improving operational efficiency.

A: Yes, the NEX-V Series complies with the universal safety standard ISO20430, ensuring adherence to global safety requirements.

A: The newly designed standard screw enhances plasticization, resulting in improved molten resin quality and better overall product integrity.

A: The NEX-V Series is designed for energy-efficient operation, reducing power consumption and operational costs while maintaining high performance.