The FNX-III Series from Nissei offers fast mold changes, versatile clamping, enhanced efficiency, improved safety, and cost-effective solutions, making it essential for optimizing productivity in injection molding.

The Nissei FNX-III Series hybrid injection molding machines combine hydraulic durability with electric efficiency, offering clamping forces from 81 to 455 tons. Equipped with Nissei’s innovative X-Pump® system, these machines deliver precise, energy-efficient performance suitable for a wide range of applications, from precision thin-wall to thick-wall molding.

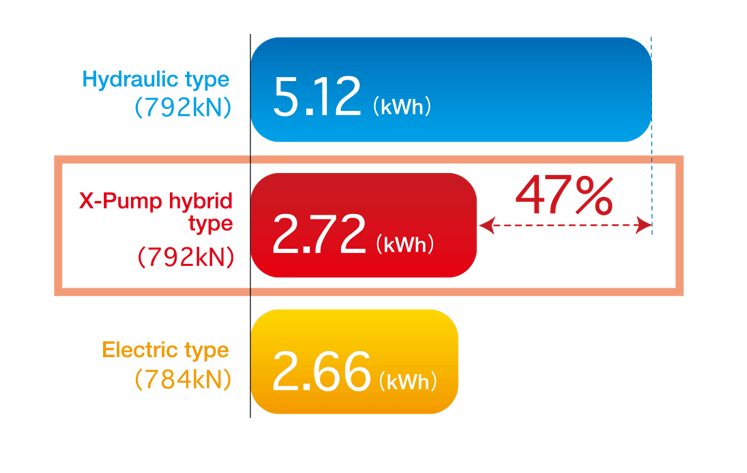

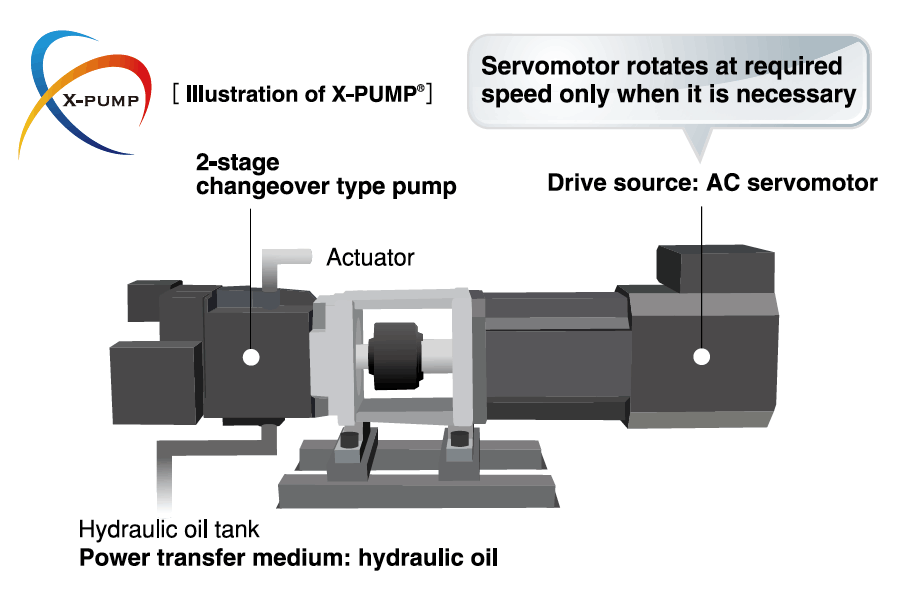

Key features of the FNX-III Series include a high-rigidity straight-hydraulic clamping unit, quick injection response, and stable control at ultra-low velocities. The X-Pump® system intelligently combines hydraulic control with servomotor drive technologies, achieving significant energy savings by operating the servomotor only as needed. The TACT® Ⅳ controller enhances operability with a 15-inch vertical LCD and user-friendly software.

Choosing the FNX-III Series provides manufacturers with a versatile solution that balances performance and cost-effectiveness. The hybrid design ensures high repeatability and low noise, while the energy-efficient X-Pump® system reduces operational costs. The advanced control interface simplifies operation, making it ideal for diverse molding requirements.

Click the dropdowns below to view detailed specifications for each model in the FNX-III Series.

| Item | Unit | 9A (std) | 12A |

|---|---|---|---|

| Screw diameter | inch (mm) | AA: 1.02 (26), A: 1.10 (28), B: 1.26 (32), C: 1.42 (36) | AA: 1.10 (28), A: 1.26 (32), B: 1.42 (36), C: 1.57 (40) |

| Injection capacity | inch³ (cm³) (oz) | 3.6 (59) (2.0), 4.2 (69) (2.3), 5.5 (90) (3.0), 7.0 (114) (3.8) | 4.7 (77) (2.6), 6.2 (101) (3.4), 7.7 (127) (4.3), 9.6 (157) (5.3) |

| Max. injection pressure | psi (MPa) (kgf/cm²) | 38470 (265) (2705), 35410 (244) (2490), 27160 (187) (1910), 21330 (147) (1500) | 38470 (265) (2705), 32850 (226) (2310), 26020 (179) (1830), 21050 (145) (1480) |

| Clamping force | USton (kN) (tf) | 89 (792) (81) | |

| Clamping stroke | inch (mm) | 18.5 (470) | |

| Min. mold thickness | inch (mm) | 7.9 (200) | |

| Max. daylight opening | inch (mm) | 26.4 (670) | |

| Tie bar clearance (H×V) | inch (mm) | 16.5×16.5 (420×420) | |

| Die plate dimensions (H×V) | inch (mm) | 22.8×22.8 (580×580) | |

| Ejector stroke | inch (mm) | 3.0 (75) |

| Item | Unit | 12A (std) | 18A |

|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.10 (28) A: 1.26 (32) B: 1.42 (36) C: 1.57 (40) |

AA: 1.26 (32) A: 1.42 (36) B: 1.57 (40) C: 1.77 (45) |

| Injection Capacity | inch³ (cm³) (oz) | 4.7 (77) (2.6) 6.2 (101) (3.4) 7.7 (127) (4.3) 9.6 (157) (5.3) |

7.1 (117) (3.9) 9.0 (147) (4.9) 11.1 (182) (6.1) 14.1 (231) (7.7) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 38400 (265) (2700) 32850 (226) (2310) 26020 (179) (1830) 21050 (145) (1480) |

38470 (265) (2705) 32280 (222) (2270) 26170 (180) (1840) 20620 (142) (1450) |

| Clamping Force | USton (kN) (tf) | 123 (1100) (112) | |

| Clamping Stroke | inch (mm) | 20.5 (520) | |

| Min. Mold Thickness | inch (mm) | 7.9 (200) | |

| Max. Daylight Opening | inch (mm) | 28.3 (720) | |

| Tie Bar Clearance (H×V) | inch (mm) | 18.1 x 18.1 (460 x 460) | |

| Die Plate Dimensions (H×V) | inch (mm) | 25.5 x 25.5 (647 x 647) | |

| Ejector Stroke | inch (mm) | 3.3 (85) |

| Item | Unit | 25A (std) | 36A |

|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.42 (36) A: 1.57 (40) B: 1.77 (45) C: 1.97 (50) |

A: 1.77 (45) B: 1.97 (50) C: 2.20 (56) |

| Injection Capacity | inch³ (cm³) (oz) | 9.9 (163) (5.5) 12.3 (201) (6.7) 15.5 (254) (8.5) 19.2 (314) (10.5) |

17.5 (286) (9.6) 21.5 (353) (11.8) 27.0 (443) (14.8) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36970 (255) (2600) 31780 (219) (2235) 25170 (173) (1770) 20340 (140) (1430) |

30010 (207) (2110) 24390 (168) (1715) 19480 (134) (1370) |

| Clamping Force | USton (kN) (tf) | 154 (1370) (140) | Same as 25A |

| Clamping Stroke | inch (mm) | 23.6 (600) | Same as 25A |

| Min. Mold Thickness | inch (mm) | 9.8 (250) | Same as 25A |

| Max. Daylight Opening | inch (mm) | 33.5 (850) | Same as 25A |

| Tie Bar Clearance (H×V) | inch (mm) | 20.1 × 20.1 (510 × 510) | Same as 25A |

| Die Plate Dimensions (H×V) | inch (mm) | 28.7 × 28.7 (730 × 730) | Same as 25A |

| Ejector Stroke | inch (mm) | 3.5 (90) | Same as 25A |

| Item | Unit | 25A | 36A (std) |

|---|---|---|---|

| Screw Diameter | inch (mm) | AA: 1.42 (36) A: 1.57 (40) B: 1.77 (45) C: 1.97 (50) |

A: 1.77 (45) B: 1.97 (50) C: 2.20 (56) |

| Injection Capacity | inch³ (cm³) (oz) | 9.9 (163) (5.5) 12.3 (201) (6.7) 15.5 (254) (8.5) 19.2 (314) (10.5) |

17.5 (286) (9.6) 21.5 (353) (11.8) 27.0 (443) (14.8) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 36970 (255) (2600) 31780 (219) (2235) 25170 (173) (1770) 20340 (140) (1430) |

30010 (207) (2110) 24390 (168) (1715) 19480 (134) (1370) |

| Clamping Force | USton (kN) (tf) | 197 (1750) (179) | Same as 25A |

| Clamping Stroke | inch (mm) | 27.6 (700) | Same as 25A |

| Min. Mold Thickness | inch (mm) | 9.8 (250) | Same as 25A |

| Max. Daylight Opening | inch (mm) | 37.4 (950) | Same as 25A |

| Tie Bar Clearance (H×V) | inch (mm) | 22.0 × 22.0 (560 × 560) | Same as 25A |

| Die Plate Dimensions (H×V) | inch (mm) | 31.5 × 31.5 (800 × 800) | Same as 25A |

| Ejector Stroke | inch (mm) | 4.3 (110) | Same as 25A |

| Item | Unit | 50A (std) | 71A |

|---|---|---|---|

| Screw Diameter | inch (mm) | A: 1.97 (50) B: 2.20 (56) C: 2.48 (63) | A: 2.20 (56) B: 2.48 (63) C: 2.80 (71) |

| Injection Capacity | inch³ (cm³) (oz) | 24.5 (402) (13.5) 30.8 (505) (16.9) 39.0 (639) (21.4) | 33.8 (554) (18.6) 42.8 (701) (23.5) 54.4 (891) (29.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 28730 (198) (2020) 22900 (158) (1610) 18200 (125) (1280) | 28440 (196) (2000) 22470 (155) (1580) 17710 (122) (1245) |

| Clamping Force | USton (kN) (tf) | 237 (2110) (215) | |

| Clamping Stroke | inch (mm) | 29.9 (760) | |

| Min. Mold Thickness | inch (mm) | 11.4 (290) | |

| Max. Daylight Opening | inch (mm) | 41.3 (1050) | |

| Tie Bar Clearance (H×V) | inch (mm) | 24.0 x 24.0 (610 x 610) | |

| Die Plate Dimensions (H×V) | inch (mm) | 34.3 x 34.3 (870 x 870) | |

| Ejector Stroke | inch (mm) | 4.7 (120) |

| Item | Unit | 71A (std) | 100A |

|---|---|---|---|

| Screw Diameter | inch (mm) | A: 2.20 (56) B: 2.48 (63) C: 2.80 (71) |

A: 2.48 (63) B: 2.80 (71) C: 3.15 (80) |

| Injection Capacity | inch³ (cm³) (oz) | A: 33.8 (554) (18.6) B: 42.8 (701) (23.5) C: 54.4 (891) (29.9) |

A: 48.5 (795) (26.6) B: 61.6 (1010) (33.8) C: 78.1 (1280) (42.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | A: 28440 (196) (2000) B: 22470 (155) (1580) C: 17710 (122) (1245) |

A: 29790 (205) (2095) B: 23390 (161) (1645) C: 18490 (127) (1300) |

| Clamping Force | USton (kN) (tf) | 309 (2740) (280) | Same as 71A |

| Clamping Stroke | inch (mm) | 32.7 (830) | Same as 71A |

| Min. Mold Thickness | inch (mm) | 12.6 (320) | Same as 71A |

| Max. Daylight Opening | inch (mm) | 45.3 (1150) | Same as 71A |

| Tie Bar Clearance (H×V) | inch (mm) | 26.0 × 26.0 (660 × 660) | Same as 71A |

| Die Plate Dimensions (H×V) | inch (mm) | 37.6 × 37.6 (955 × 955) | Same as 71A |

| Ejector Stroke | inch (mm) | 5.1 (130) | Same as 71A |

| Item | Unit | 100A (std) | 140A |

|---|---|---|---|

| Screw diameter | inch (mm) | A: 2.48 (63) B: 2.80 (71) C: 3.15 (80) | A: 2.80 (71) B: 3.15 (80) C: 3.54 (90) |

| Injection capacity | inch³ (cm³) (oz) | A: 48.5 (795) (26.6) B: 61.6 (1010) (33.8) C: 78.1 (1280) (42.9) | A: 67.7 (1100) (37.2) B: 86.0 (1410) (47.2) C: 108.6 (1780) (59.6) |

| Max. injection pressure | psi (MPa) (kgf/cm²) | A: 29790 (205) (2095) B: 23390 (161) (1645) C: 18490 (127) (1300) | A: 28390 (195) (1990) B: 22330 (154) (1570) C: 17710 (122) (1245) |

| Clamping force | USton (kN) (tf) | 398 (3540) (361) | 398 (3540) (361) |

| Clamping stroke | inch (mm) | 38.2 (970) | 38.2 (970) |

| Min. mold thickness | inch (mm) | 13.8 (350) | 13.8 (350) |

| Max. daylight opening | inch (mm) | 52.0 (1320) | 52.0 (1320) |

| Tie bar clearance (H×V) | inch (mm) | 28.9 x 28.9 (735 x 735) | 28.9 x 28.9 (735 x 735) |

| Die plate dimensions (H×V) | inch (mm) | 41.5 x 41.5 (1055 x 1055) | 41.5 x 41.5 (1055 x 1055) |

| Ejector stroke | inch (mm) | 5.9 (150) | 5.9 (150) |

| Item | Unit | 160A (std) |

|---|---|---|

| Screw diameter | inch (mm) | A: 2.80 (71) B: 3.15 (80) C: 3.54 (90) |

| Injection capacity | inch³ (cm³) (oz) | A: 77.5 (1270) (42.6) B: 98.2 (1610) (54.0) C: 123.9 (2030) (68.0) |

| Max. injection pressure | psi (MPa) (kgf/cm²) | A: 28390 (195) (1990) B: 22330 (154) (1570) C: 17710 (122) (1245) |

| Clamping force | USton (kN) (tf) | 501 (4460) (455) |

| Clamping stroke | inch (mm) | 40.4 (1025) |

| Min. mold thickness | inch (mm) | 14.8 (375) |

| Max. daylight opening | inch (mm) | 55.1 (1400) |

| Tie bar clearance (H×V) | inch (mm) | 32.3 × 32.3 (820 × 820) |

| Die plate dimensions (H×V) | inch (mm) | 46.9 × 46.9 (1190 × 1190) |

| Ejector stroke | inch (mm) | 6.3 (160) |

A: The series offers clamping forces ranging from 81 to 455 tons, accommodating various molding needs.

A:The X-Pump® system operates the servomotor only when necessary, leading to significant energy savings compared to traditional hydraulic systems.

A: The TACT® Ⅳ controller features a 15-inch vertical LCD and user-friendly software, enhancing visibility and operability for efficient machine control.

A: Yes, the FNX-III Series is designed for a wide variety of molding applications, from precision thin-wall to thick-wall products.

A: The hybrid design combines the low maintenance costs of hydraulic machines with the precision of electric servomotors, resulting in long-lasting precision and reduced upkeep.