The VECTOR sT Series from Negri Bossi offers advanced servo-hydraulic technology, high injection speeds, and energy-efficient performance, making it ideal for large-scale and versatile injection molding applications.

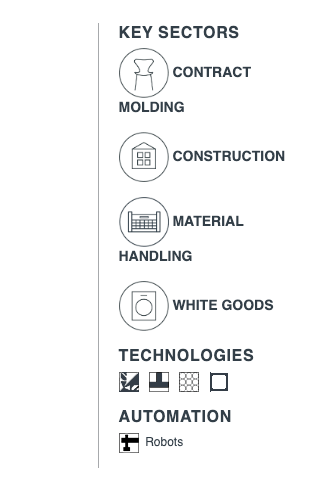

The VECTOR sT Series from Negri Bossi comprises 5-point double toggle clamp, hybrid injection molding machines available in 650-, 800-, 1100-, and 1300-tonne models. Designed with energy efficiency in mind, these machines incorporate advanced servo-pump technology tailored for injection molding applications, ensuring high performance and reliability across various industrial sectors.

The VECTOR sT machines are equipped with the MOTUS Multi-Touch Controller, featuring an innovative gesture navigation system with swipe, scroll, and zoom functions. The Smart Flex clamping unit offers generous tie bar spacing to accommodate larger molds, complemented by long ejector strokes and a robust in-line injection unit. Notably, material pressure has been increased by over 15%, and injection speed enhanced by over 25% through regeneration.

Selecting the VECTOR sT Series ensures enhanced productivity through faster injection speeds and improved material pressure. The energy-efficient servo-pump technology reduces operational costs, while the MOTUS Multi-Touch Controller provides intuitive operation. Its versatile design accommodates larger molds, making it suitable for a wide range of injection molding applications, delivering both efficiency and flexibility.

Click the dropdowns below to view detailed specifications for the VECTOR sT (650–1300 tonnes).

MAIN CHARACTERISTICS

The VECTOR sT Series (650-1300 tonnes) from Negri Bossi integrates advanced servo-hydraulic technology and cutting-edge innovations to deliver precision, energy efficiency, and exceptional reliability. Perfect for large-scale injection molding, it supports demanding manufacturing applications.

X-DESIGN TOGGLE SYSTEM

The X-Design toggle mechanism ensures stability and compactness, providing optimal force transmission and minimizing mold wear. This system enhances mold longevity while maintaining high-speed, dynamic performance for heavy-duty operations.

ADVANCED SERVO-PUMP TECHNOLOGY

Equipped with state-of-the-art servo-pump technology, the VECTOR sT offers outstanding energy efficiency, quiet operation, and precise control. This makes it ideal for high-demand manufacturing environments requiring reliable performance.

HIGH-DYNAMIC PLATEN MOVEMENT

The VECTOR sT features advanced platen dynamics with sensitive mold protection and automatic clamping adjustments. These features enhance mold safety, reduce production downtime, and improve overall efficiency.

PRISMATIC LINEAR GUIDES

With prismatic linear guides, the VECTOR sT ensures accurate platen alignment, smooth movement, and a clean operating environment. This design promotes precise mold positioning and consistently high-quality output.

MOTUS CONTROLLER

The advanced Motus multi-touch controller delivers intuitive gesture-based navigation, customizable user interfaces, and real-time monitoring, providing operators with an efficient and user-friendly experience.

COMPACT FOOTPRINT

The VECTOR sT Series boasts a space-saving design, reducing its footprint by up to 15% compared to similar models. This allows for optimized factory layouts and enhanced production capacity.

ENERGY EFFICIENCY

The energy-optimized design of the VECTOR sT reduces power consumption without compromising performance. This feature helps manufacturers cut costs while meeting sustainability objectives.

ROBUST CLAMPING SYSTEM

The VECTOR sT’s robust clamping system is engineered to handle large molds and heavy-duty applications, ensuring reliable and consistent production cycles.

These features make the VECTOR sT (650-1300 tonnes) a premier choice for manufacturers prioritizing precision, efficiency, and versatility in large-scale injection molding operations.

A: The VECTOR sT Series offers models with clamping forces of 650, 800, 1100, and 1300 tonnes.

A: The MOTUS Controller features an innovative gesture navigation system, including swipe, scroll, and zoom functions, providing intuitive and efficient machine control.

A: The VECTOR sT Series achieves over a 15% increase in material pressure and a 25% increase in injection speed through regeneration, enhancing overall productivity.

A: Yes, the VECTOR sT incorporates advanced servo-pump technology designed specifically for injection molding, ensuring high energy efficiency.

A: Absolutely, the Smart Flex clamping unit provides generous tie bar spacing, making it suitable for larger molds used in various industrial applications.