The NOVA sT Series (180-500 tonnes) from Negri Bossi combines precision molding, advanced servo-pump technology, energy efficiency, and user-friendly control, ideal for versatile manufacturing.

The NOVA sT Series by Negri Bossi comprises servo-powered toggle injection molding machines with clamping forces ranging from 180 to 500 tonnes. Designed for sectors such as automotive, electrical, construction, and technical molding, these machines offer enhanced energy efficiency and versatility. Equipped with advanced servo-pump technology, they ensure precise and efficient molding operations, meeting diverse industry requirements.

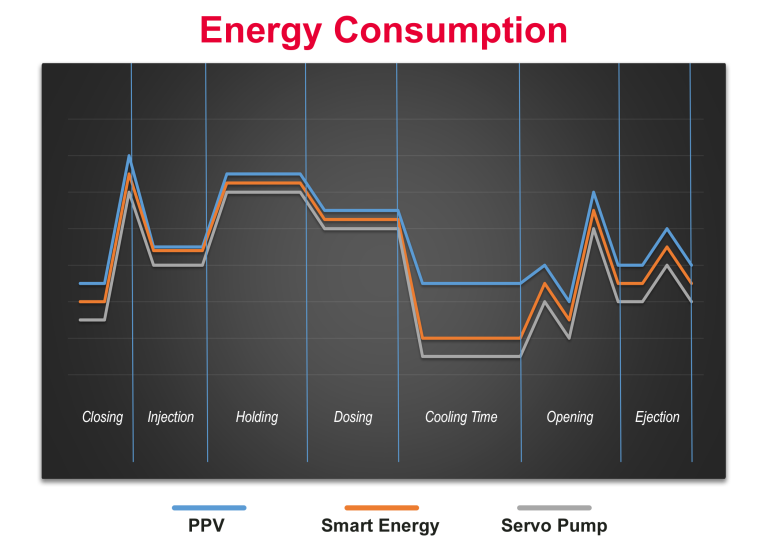

The NOVA sT Series features a 5-point double toggle clamp system and the MOTUS multi-touch controller for intuitive operation. With models available in 180, 250, 330, 400, and 500 tonnes, they incorporate twin servo pumps (single on model ST180) for simultaneous function operations, enhancing productivity. The moving platen rides on linear bearings, ensuring excellent parallelism and reduced energy consumption. Additionally, the robust in-line swinging injection unit with a quick-release barrel facilitates easy maintenance.

Selecting the NOVA sT Series means investing in machines that prioritize energy efficiency, operational versatility, and user-friendly interfaces. The advanced servo-pump technology reduces energy consumption, lowering operational costs. The generous tie bar spacing accommodates larger molds, expanding production capabilities. Furthermore, the MOTUS controller simplifies machine operation, enhancing overall productivity.

Click the dropdowns below to view detailed specifications for the NOVA sT (180-500 tonnes).

MAIN CHARACTERISTICS

The NOVA sT Series from Negri Bossi integrates cutting-edge technology to deliver unmatched precision, efficiency, and reliability in injection molding. These features make it a standout solution for various applications.

The innovative flat clamp mechanism ensures optimal contact pressure, reducing toggle bush loading and minimizing wear on molds. This design prolongs mold life, reduces the clamp force required, and improves overall production efficiency.

The advanced toggle system offers faster open/close speeds, high-sensitivity mold protection, and automatic force adjustments. This ensures the safety of your molds while enhancing productivity.

Equipped with prismatic linear platen guides, the NOVA sT guarantees precise platen guidance, energy-efficient operations, and a clean production environment.

Designed for cleanroom environments, the NOVA sT features reduced particle emissions, centralized grease lubrication, and complies with Cleanroom Class 10,000 standards.

The TACT V system combines user-friendly touch control with connectivity features, providing intuitive operation and seamless integration with production environments.

This feature stabilizes check valve response, ensures consistent volume and melt density, and adapts to batch inconsistencies or regrind material, ensuring reliable performance.

The EG Injection Units deliver reduced heat-up time, shorter plasticizing cycles, and improved molding stability, ensuring superior molding precision.

The NOVA sT Series boasts a 15% smaller footprint than its predecessor, allowing for more machines in the same area and maximizing factory output.

These advanced features make the NOVA sT (180-500 tonnes) the ideal choice for manufacturers seeking energy-efficient, precise, and reliable injection molding solutions.

A: The series offers models with clamping forces of 180, 250, 330, 400, and 500 tonnes.

A:Twin servo pumps allow simultaneous operations, such as ejector and core actions during clamp movement, enhancing efficiency.

A: They are ideal for automotive, electrical, construction, and technical molding sectors.

A: MOTUS is a multi-touch controller that provides an intuitive interface for machine operation, improving user experience.

A: The moving platen rides on linear bearings, ensuring excellent parallelism and reduced energy consumption during operations.