The BIPOWER Series (1300-7000 tonnes) from Negri Bossi delivers hybrid-powered precision, energy efficiency, and robust performance, ideal for large-scale injection molding across diverse industries.

The BIPOWER Series from Negri Bossi comprises hybrid-powered, two-platen injection molding machines ranging from 1300 to 7000 tonnes. Designed for sectors like automotive, environmental, construction, and material handling, these machines offer high modularity and accessibility, making them ideal for large-scale manufacturing applications.

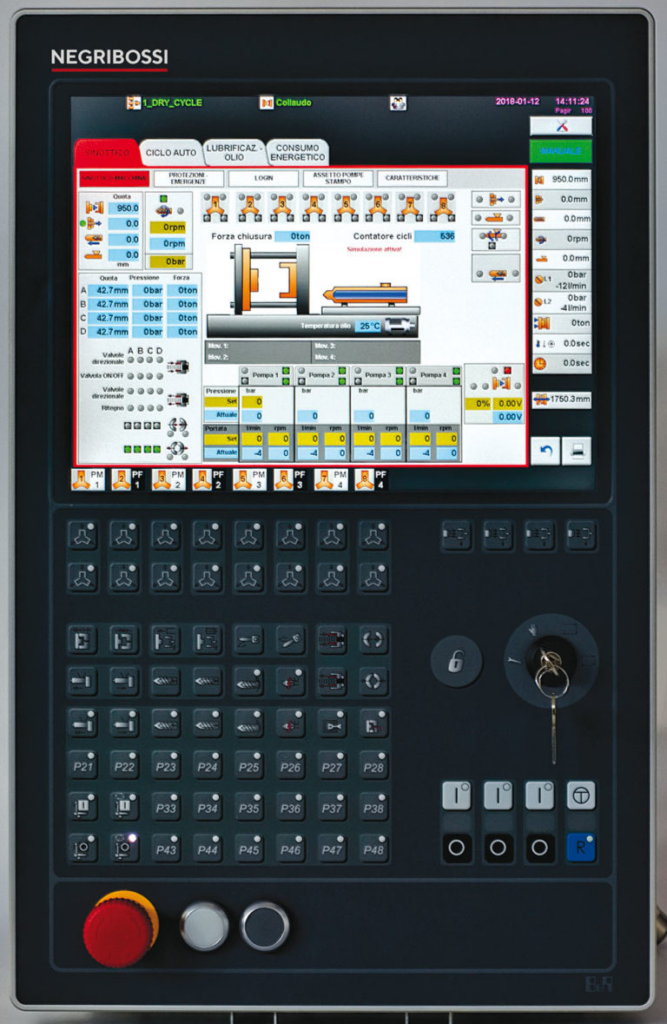

BIPOWER machines feature a robust two-platen clamping unit with generous tie bar spacing and clamping pistons on the moving platen, ensuring high rigidity and minimal deflection. The injection unit includes a reciprocating screw with electric screw rotation, providing precise control and energy savings. Additionally, the user-friendly C-TOUCH interface offers comprehensive control parameters for efficient operation.

Selecting the BIPOWER Series ensures reliable performance due to its robust design and advanced hybrid technology. The compact two-platen configuration saves floor space, enhancing facility layout flexibility. Energy-efficient components reduce operational costs, while the machine’s versatility makes it suitable for various industrial applications, delivering both efficiency and adaptability.

Click the dropdowns below to view detailed specifications for the BIPOWER (1300-7000 tonnes).

MAIN CHARACTERISTICS

The BIPOWER Series (1300-7000 tonnes) from Negri Bossi combines hybrid-powered precision and innovative engineering to deliver unmatched reliability, energy efficiency, and superior performance. Ideal for large-scale injection molding, it meets the demands of diverse industrial applications.

TWO-PLATEN CLAMPING SYSTEM

The BIPOWER Series features a robust two-platen clamping mechanism, ensuring optimal force distribution and minimal deflection. This design enhances mold longevity and ensures consistent, high-quality results for heavy-duty operations.

HYBRID POWER TECHNOLOGY

Equipped with advanced hybrid technology, the BIPOWER Series combines hydraulic and electric systems to achieve exceptional energy savings, precise control, and quiet operation. This makes it an ideal choice for high-demand environments requiring reliable performance.

HIGH-DYNAMIC PLATEN MOVEMENT

With advanced platen dynamics, the BIPOWER Series offers sensitive mold protection and automatic clamping adjustments. These features reduce mold wear, enhance safety, and improve production efficiency for large-scale manufacturing.

PRISMATIC LINEAR GUIDES

The inclusion of prismatic linear guides ensures precise platen alignment and smooth operation. This guarantees accurate mold positioning, a clean working environment, and consistently high-quality output.

C-TOUCH CONTROLLER

The user-friendly C-TOUCH controller provides an intuitive interface, real-time monitoring, and customizable settings. Operators benefit from seamless control and efficiency in managing complex production processes.

SPACE-SAVING DESIGN

The compact two-platen configuration of the BIPOWER Series minimizes its footprint, optimizing factory layouts and increasing overall production capacity, making it suitable for facilities with space constraints.

ENERGY EFFICIENCY

The hybrid design reduces power consumption without sacrificing performance, helping manufacturers lower operational costs while meeting sustainability goals in large-scale production.

ROBUST CLAMPING SYSTEM

Designed for heavy-duty applications, the BIPOWER Series accommodates large molds with ease, delivering stable and reliable production cycles for demanding industries like automotive and construction.

These advanced features make the BIPOWER Series (1300-7000 tonnes) a leading solution for manufacturers seeking efficiency, versatility, and reliability in large-scale injection molding operations.

A: BIPOWER machines are ideal for automotive, environmental, construction, and material handling sectors.

A: The BIPOWER Series offers clamping forces ranging from 1300 to 7000 tonnes.

A: The hybrid system combines electric and hydraulic technologies, enhancing energy efficiency and performance.

A: The two-platen design provides a compact footprint, high rigidity, and minimal deflection, improving molding precision.

A: Yes, BIPOWER machines come equipped with AMICO wireless remote service access for efficient troubleshooting.