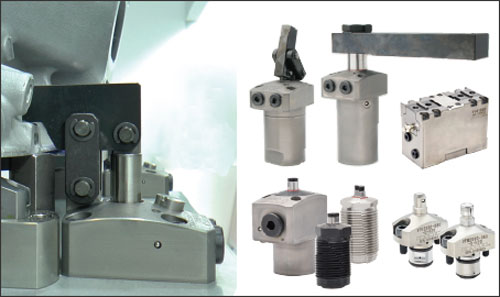

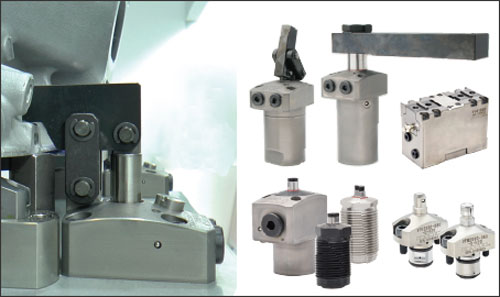

Kosmek’s Machine Tools offer unmatched precision and reliability, making them indispensable in modern manufacturing. These advanced tools optimize machining processes with innovative designs and superior performance.

Kosmek’s Machine Tools are at the forefront of industrial innovation, streamlining machining processes for enhanced productivity. Essential in industries like automotive and aerospace, they provide precise cutting, shaping, and forming solutions. Their robust design ensures longevity and consistent performance, making them a vital asset for manufacturers aiming for precision and efficiency.

Kosmek Machine Tools are renowned for their precision engineering, efficient automation integration, and ergonomic designs. These tools reduce setup times while delivering high reliability and exceptional accuracy. Featuring advanced clamping systems and durable materials, they excel in demanding industrial applications, ensuring seamless operation and reduced downtime.

Kosmek Machine Tools enhance production efficiency, reduce operational costs, and ensure precise manufacturing. Their innovative designs simplify complex tasks, offering unparalleled reliability. Choosing Kosmek tools means investing in long-term performance and productivity, empowering businesses to meet modern manufacturing challenges.

Click the dropdowns below to view detailed information for each model in the Machine Tools Series.

| Hole Clamps | |

|---|---|

| Clamping Diameter Range | Varies per model; consult specifications |

| Clamping Force | High clamping force suitable for various materials |

| Operating Pressure | Consult model-specific data |

| Features | Secure internal clamping, suitable for automated systems, enhances machining accuracy |

| Swing Clamps | |

|---|---|

| Clamping Stroke | Varies per model; consult specifications |

| Swing Angle | Standard 90°; other angles available |

| Operating Pressure | Consult model-specific data |

| Features | Quick clamping action, lever swings away for easy access, adaptable to various setups |

| Link Clamps | |

|---|---|

| Clamping Force | High force suitable for heavy-duty applications |

| Operating Pressure | Consult model-specific data |

| Features | Compact design, high rigidity, suitable for confined spaces |

| Side Clamps | |

|---|---|

| Clamping Stroke | Varies per model; consult specifications |

| Clamping Force | Suitable for various workpiece sizes |

| Operating Pressure | Consult model-specific data |

| Features | Side access clamping, keeps top surface clear, ideal for multi-face machining |

| Work Supports | |

|---|---|

| Support Stroke | Varies per model; consult specifications |

| Load Capacity | Suitable for various workpiece weights |

| Operating Pressure | Consult model-specific data |

| Features | Reduces vibration, enhances machining accuracy, adaptable to various setups |

| Link Clamp – Retracting Model | |

|---|---|

| Clamping Force | High force with retractable lever |

| Retracting Stroke | Varies per model; consult specifications |

| Operating Pressure | Consult model-specific data |

| Features | Retractable lever design, prevents interference, suitable for complex machining tasks |

| Centering Vises | |

|---|---|

| Jaw Opening Range | 50-150 mm |

| Clamping Force | 10-30 kN |

| Base Dimensions | 120 x 150 mm to 200 x 300 mm |

| Features | High centering precision, adjustable jaws for various workpiece sizes, built-in guides for stability |

| Hydraulic Cylinders | |

|---|---|

| Stroke Length | 10-100 mm |

| Operating Pressure | 5-20 MPa |

| Body Dimensions | 50 x 80 mm to 120 x 200 mm |

| Features | Precision control, durable construction, suitable for heavy-duty machining setups |

| Workholding Fixtures | |

|---|---|

| Clamping Surface Dimensions | 200 x 300 mm to 500 x 700 mm |

| Weight Capacity | Up to 500 kg |

| Material | Hardened steel or aluminum alloy |

| Features | Customizable designs, anti-vibration properties, high precision clamping |

| Pneumatic Clamps | |

|---|---|

| Clamping Force | 5-15 kN |

| Operating Pressure | 0.5-1 MPa |

| Stroke Length | 20-60 mm |

| Features | Quick actuation, compatible with automation systems, low maintenance design |

A: Kosmek Machine Tools are ideal for automotive, aerospace, and precision manufacturing industries.

A: Advanced clamping systems, automation compatibility, and ergonomic designs set them apart.

A: Yes, regular maintenance and proper usage ensure optimal performance and longevity.

A: Absolutely, they are designed for seamless automation integration.

A: Please contact one of our expert consultants to find exactly what you’re looking for.