Quick mold change systems deliver fast mold changes, versatile clamping, enhanced efficiency, improved safety, and cost-effective solutions, making them essential for optimizing productivity in manufacturing.

Kosmek’s Quick Mold Change Systems (QMCS) are engineered to significantly reduce mold change times in injection molding processes, enhancing operational efficiency across various manufacturing sectors. By integrating advanced clamping technologies, QMCS facilitate rapid and secure mold transitions, minimizing downtime and boosting productivity. These systems are essential for manufacturers aiming to optimize production cycles and maintain high-quality output.

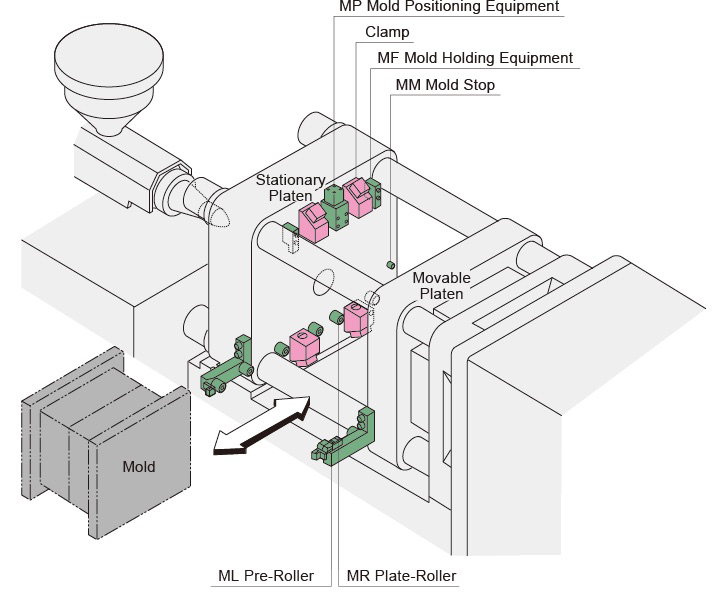

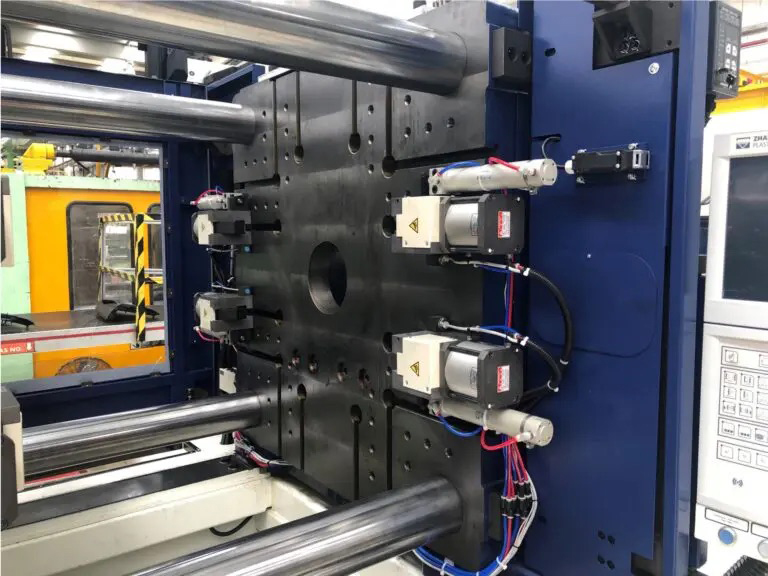

Key features of Kosmek’s QMCS include versatile clamping options such as hydraulic, pneumatic, and magnetic clamps, accommodating diverse mold specifications. The systems support both vertical and horizontal mold loading, providing flexibility to suit different operational setups. Additionally, QMCS offer automated processes for mold positioning and clamping, reducing manual intervention and enhancing safety during mold changes.

Choosing Kosmek’s QMCS enables manufacturers to achieve faster mold changes, leading to increased production efficiency and reduced labor costs. The systems’ adaptability to various mold sizes and types ensures seamless integration into existing operations. Enhanced safety features further contribute to a secure working environment, making QMCS a valuable investment for companies seeking to improve their manufacturing processes.

Click the dropdowns below to view detailed information for each model in the Quick Mold Change Systems Series.

Overview:

Magnetic clamping systems that dramatically reduce mold changing time. These clamps ensure safety and eliminate the need for standardized mold sizes, making operations efficient and flexible.

Overview:

A T-slot manual-slide lever clamp designed for non-standardized mold widths. This single-action clamp allows easy manual sliding for secure mold clamping, providing versatility in operations.

Overview:

An air cylinder-powered T-slot automatic-slide clamp that enables remote-controlled mold locking. The GBE clamp combines automation with efficiency, ideal for high-volume applications.

Overview:

Featuring a longer stroke for accommodating variations in mold clamping thickness, this T-slot automatic-slide clamp uses an air cylinder for effortless remote-controlled operation.

Overview:

A T-slot automatic-slide clamp that combines mechanical lock, air pressure, and spring force for secure mold clamping. It features automated sliding and locking via remote control for maximum convenience.

Overview:

A fixed-type pneumatic clamp that matches hydraulic clamping force. Its mechanical lock function ensures safety by maintaining pressure even when air supply drops to zero, making it highly reliable.

Overview:

A compact control unit and palm-sized operation panel designed for use with Magnetic Clamps. It enables easy monitoring and control of clamping force, enhancing safety and usability.

Overview:

An air cylinder-powered block-fixed clamp that eliminates the need for T-slots. It automatically slides and locks into position, making it ideal for non-standardized mold widths and flexible operations.

A: Kosmek offers hydraulic, pneumatic, and magnetic clamping systems to accommodate various mold specifications and operational requirements.

A:Yes, QMCS support both vertical and horizontal mold loading, providing flexibility for different mold sizes and manufacturing setups.

A: he systems incorporate automated processes for mold positioning and clamping, reducing manual intervention and minimizing the risk of accidents during mold changes.

A: Industries involved in injection molding processes, such as automotive, electronics, and consumer goods manufacturing, can significantly benefit from the efficiency and safety enhancements provided by QMCS.

A:By reducing mold change times and labor requirements, QMCS help lower operational costs and increase overall production efficiency.