HSG Tube Lasers are engineered to cut complex tube shapes with speed, accuracy, and full automation. With advanced chuck technology, intelligent control systems, and smart software, these machines are ideal for industrial tube processing.

HSG Tube Lasers are engineered to cut complex tube shapes with speed, accuracy, and full automation. With advanced chuck technology, intelligent control systems, and smart software, these machines are ideal for industrial tube processing.

HSG tube laser systems deliver precision, efficiency, and consistency in cutting round, square, rectangular, and custom-profile tubing. Designed for diverse industrial applications, these advanced systems handle mild steel, stainless steel, aluminum, and more, making them ideal for OEMs, contract manufacturers, and structural fabricators. Equipped with cutting-edge technology like auto-loading, bevel cutting, and intelligent clamping, they help boost productivity, reduce secondary operations, and ensure reliable results across a wide range of manufacturing demands.

Easy-to-Use CNC System

Intelligent Digital Four Chucks

“3+1” Twin-Chuck Clamping System

Rich Tube Cutting Library

High Precision & Zero Tailing

Intelligent Automation

Built to Last

Click the dropdowns below to view detailed specifications for the Tube Lasers.

Specification | Metric | Imperial |

Laser Power | 1.5kW – 6kW | 1500W – 6000W |

Tube Processing Range | R1 Round tube: 8mm – 120mm Square tube: 8mm x 8mm – 120mm x 120mm Side Length: 8mm – 120mm R2 Round tube: 8mm – 240mm Square tube: 8mm x 8mm – 240mm x 240mm Side Length: 8-240mm R3 Round tube: 20mm – 325mm Square tube: 20mm x 20mm – 230mm x 230mm Diagonal≤325mm | R1 Round tube: 0.31in- 4.72in Square tube: 0.31in x 0.31in – 4.72in x 4.72in Side Length: 0.31in – 4.72in R2 Round tube: 0.31in- 9.45in Square tube: 0.31in x 0.31in – 9.45in x 9.45in Side Length: 0.31in – 9.45in R3 Round tube: 0.79in – 12.80in Square tube: 0.79in x 0.79in – 9.06in x 9.06in Diagonal≤12.80in |

Range of Incoming Materials for Tube | 1000mm – 6500mm | 39.37in – 255.91in |

Positioning Precision of X/Y Axis | ±0.05mm/m | ±0.00059in/ft |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.0012mm |

Speed of Chuck | 150 RPM (R1) 100 RPM (R2) 90 RPM(R3) | |

Max Linkage Speed | 150 m/min (R1) 120 m/min (R2) 90 m/min (R3) | 492ft/min (R1) 393.7ft/min (R2) 295.28ft/min (R3) |

Max Linkage Acceleration | 1.5 G (R1) 1.0 G (R2) 0.8 G (R3) | |

Max Single Tube Weight | About 50 kg (R1) About 300kg (R2) About 200kg (R3) | About 110lb (R1) About 661lb (R2) About 441lb (R3) |

Bevel Option | No | |

Core Attributes | R1 Compact, High-Speed Tube Laser Cutter: Tailored for precision work on small-diameter tubes Real-Time Tube Support: Adaptive follow-up support ensures stable, accurate cutting Smart Bus-Controlled Operation: Delivers responsive performance and intuitive system management R2 Versatile Dual-Chuck Tube Laser Cutter: Engineered for a wide range of pipe and profile shapes Standard Rectangular & Circular Chuck Setup: Handles multiple tube geometries with ease Smooth, High-Speed Motion Control: Enhanced dynamics enable faster cycles and increased throughput R3 Cost-Effective Tube Laser Cutting Solution: Efficient performance in a compact footprint Space-Saving Design: Small form factor ideal for workshops with limited floor space Pneumatic Chuck System: One-click opening with automatic centering for faster setup Double-Row Roller Clamping: Provides stable holding force to maintain cutting accuracy | |

Specification | Metric | Imperial |

Laser Power | 3kW – 6kW | 3000W – 6000W |

Tube Processing Range | T2 Round tube: 20mm – 240mm Square tube: 20mm x 20mm – 240mm x 240mm Diagonal≤330mm T3 Round tube: 20mm – 350mm Square tube: 20mm x 20mm – 350mm x 350mm Diagonal≤495mm | T2 Round tube: 0.79in – 9.45in Square tube: 0.79in x 0.79in – 9.45in x 9.45in Diagonal≤13in T3 Round tube: 0.79in – 13.78in Square tube: 0.79in x 0.79in – 13.78in x 13.78in Diagonal≤19.5in |

Range of Incoming Materials for Tube | 1000mm – 7000mm (T2) 1000mm – 9000mm (T3) | 39.37in – 275.59in (T2) 39.37in – 354.33in (T3) |

Positioning Precision of X/Y Axis | ±0.03mm/m (T2) ±0.05mm/m (T3) | ±0.00035 in/ft (T2) ±0.00059 in/ft (T3) |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.00118in |

Speed of Chuck | 100 RPM (T2) 80 RMP (T3) | |

Max Linkage Speed | 100 m/min (T2) 80 m/min(T3) | 328ft/min (T2) 262ft/min (T3) |

Max Linkage Acceleration |

0.8 G (T3) | |

Max Single Tube Weight | About 300kg (T2) About 600kg (T3) | About 661lb (T2) About 1323lb (T3) |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

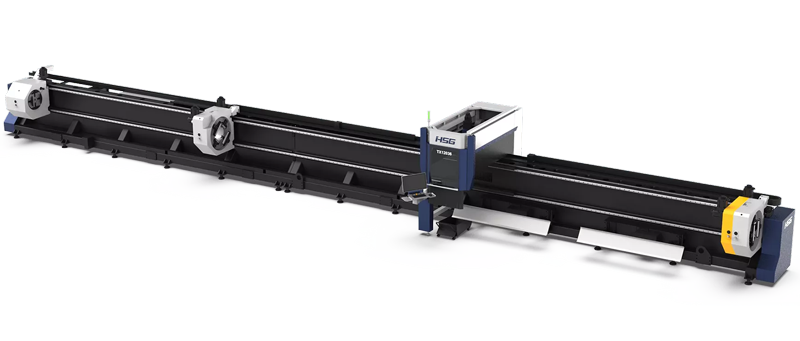

Core Attributes | Three-Chuck Tube Laser Cutter: Delivers precise control and strong clamping for long and complex tubes Independent Servo-Driven Support: Adaptive follow-up system ensures accuracy during high-speed cutting Smart Bus Control Platform: Offers seamless operation with intelligent automation features Fully Mobile Three-Chuck System: Flexible configuration allows for enhanced material handling and positioning | |

Specification | Metric | Imperial |

Laser Power | 6kW – 20kW | 6000W – 20000W |

Tube Processing Range | TX12036 Round tube: 50mm – 500mm Square tube: 50mm x 50mm – 350mm x 350mm Diagonal≤500mm TX12050 Round tube: 40mm- 360mm Square tube: 40mm x 40mm – 250mm x 250mm Diagonal≤360mm | TX12036 Round tube: 1.97in – 19.69in Square tube: 1.97in x 1.97in – 13.78in x 13.78in Diagonal≤19.69in TX12050 Round tube: 1.57in – 14.17in Square tube: 1.57in x 1.57in – 9.84in x 9.84in Diagonal≤14.17in |

Range of Incoming Materials for Tube | 2000mm – 12000mm (TX12036) 2500mm – 12000mm (TX12050) | 78.74in – 472.44in (TX12036) 98.43in – 472.44in (TX12050) |

Positioning Precision of X/Y Axis | ±0.05mm/m | ±0.00059 in/ft |

Repetitive Positioning Precision of X/Y Axis | ±0.05mm | ±0.0020 in |

Speed of Chuck | 60 RPM (TX12036) 40 RMP (TX12050) | |

Max Linkage Speed | 60m/min | 196.85 ft/min |

Max Linkage Acceleration | 0.6 G (TX12036) 0.3 G (TX12050) | |

Max Single Tube Weight | About 1200kg (TX12036) About 1500kg (TX12050) | About 2645lb (TX12036) About 3306lb (TX12050) |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

Core Attributes | 3+1 Twin-Chuck Tube Laser Cutter: Optimized layout with dual chucks plus auxiliary support for enhanced control Heavy-Duty Tube Handling: Multi-point support system ensures stability and precision during the cutting process | |

Specification | Metric | Imperial |

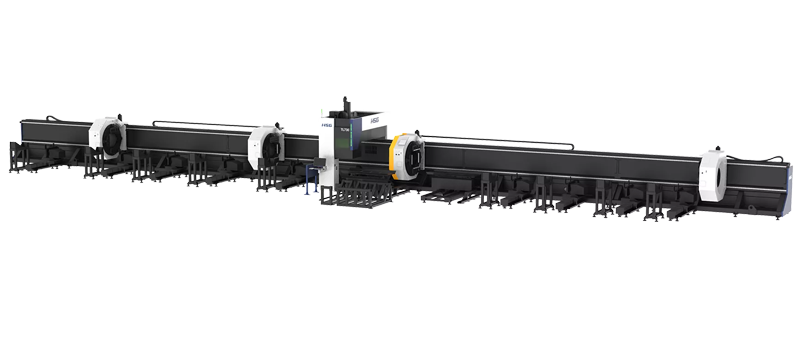

Laser Power | 6kW – 20kW | 6000W – 20000W |

Tube Processing Range | TL660 Round tube: 80mm – 660mm Square tube: 80mm x 80mm – 450mm x 450mm Diagonal≤660mm Side Length≥80mm TL730S Round tube: 120mm- 715mm Square tube: 120mm x 120mm – 500mm x 500mm Diagonal≤715mm Side Length: 120mm-500mm | TL660 Round tube: 3.15” – 25.98in Square tube: 3.15in x 3.15in – 17.72in x 17.72in Diagonal≤25.98in Side Length≥3.15in TL730S Round tube: 4.72in – 28.15in Square tube: 4.72in x 4.72in – 19.69in x 19.69in Diagonal≤28.15in Side Length: 4.72in – 19.69in |

Range of Incoming Materials for Tube | 3000mm – 12000mm (TL660) 3000mm – 16000mm (TL730S) | 118.11in – 472.44in (TL660) 118.11in – 629.92in (TL730S) |

Positioning Precision of X/Y Axis | ±0.01mm/m | ±0.00012 in/ft |

Repetitive Positioning Precision of X/Y Axis | ±0.01mm | ±0.00039 in |

Speed of Chuck | 30 RPM | |

Max Linkage Speed | 50m/min (TL660) 45m/min (TL730S) | 164ft/min (TL660) 147.6ft/min (TL730S) |

Max Linkage Acceleration | 0.2 G | |

Max Single Tube Weight | About 3000kg (TL660) About 4000kg (TL730S) | About 6614lb (TL660) About 8818lb (TL730S) |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

Core Attributes | Four-Chuck Tube Laser Cutter for Heavy-Duty Applications: Engineered for ultra-stable processing of long, large-diameter tubes Zero-Tail Cutting Capability: Maximizes material usage by eliminating waste at the tube end Optional Automated Handling: Supports automatic loading and unloading systems designed specifically for heavy tube operations | |

Specification | Metric | Imperial |

Laser Power | 3kW – 6kW | 3000W – 6000W |

Tube Processing Range | Round tube: 12mm – 254mm Square tube: 20mm x 20mm – 200mm x 200mm Side Length≤200mm | Round tube: 0.47in – 10in Square tube: 0.79in x 0.79in – 7.87in x 7.87in Side Length≤7.87in |

Range of Incoming Materials for Tube | 1000mm – 6500mm | 39.37in – 255.91in |

Positioning Precision of X/Y Axis | ±0.03mm/m | ±0.00035 in/ft |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.00118 in |

Speed of Chuck | 120 RMP | |

Max Linkage Speed | 120m/min | 393.7 ft/min |

Max Linkage Acceleration | 1.2 G | |

Max Single Tube Weight | About 200kg | About 441lb |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

Core Attributes | All-in-One Processing: Combines cutting, drilling, and tapping in a single, streamlined machine High-Speed Precision: Capable of producing complex patterns with accuracy and efficiency Optional Automated Material Handling: Supports advanced loading and unloading systems for uninterrupted productivity | |

A: HSG Tube Lasers can cut round, square, rectangular, oval, hexagonal, and other irregular or custom profiles. They’re also capable of cutting angle iron and channel steel, making them highly versatile for industrial applications.

A: Yes — HSG Tube Lasers support true “0 tailing”. With advanced chuck systems like the “3+1” twin-chuck setup and intelligent four-chuck clamping, the machine can use 100% of the tube length, eliminating waste at the end of each part.

A: HSG systems use intelligent, self-adjusting chucks that automatically adapt to tube size and weight. This ensures stable clamping even for heavy and ultra-heavy tubes and maintains high cutting accuracy without manual intervention.

A: HSG Tube Lasers come equipped with automatic loading and unloading systems, wireless data transmission, real-time clamping feedback, and automatic correction of tube deformation — all designed to reduce manual labor and speed up production.

A: Yes. The clamping system is engineered for long-length and heavy tubes, providing stable support and synchronized movement to ensure consistent cut quality — even on challenging workpieces.

A: HSG Tube Lasers can process a wide range of tubing diameters, typically from φ20 mm to φ350 mm (0.8″ to 13.8″), depending on the model. Ultra-large systems can accommodate even larger diameters for heavy industrial applications.

A: Yes — HSG Tube Lasers feature the HSG-X BUS CNC system, which is user-friendly and intuitive. Operators can learn quickly, and the interface includes smart tools like nesting, job queues, cutting libraries, and real-time diagnostics.

A: HSG’s built-in library includes nearly 100 pre-programmed joggling and splicing patterns — including tee joints, 45° angles, arc splicing, and weld prep geometries. This saves programming time and ensures consistency for welding and assembly.

A: HSG Tube Lasers are built for industrial durability and feature low-maintenance linear systems. Preventative maintenance is simple and supported by remote diagnostics and local service partners.

A: HSG Tube Lasers are available in a range of customizable power levels, typically from 1.5kW to 12kW+ depending on tube thickness, material, and production speed. Sales teams help match the right wattage to your job specs.