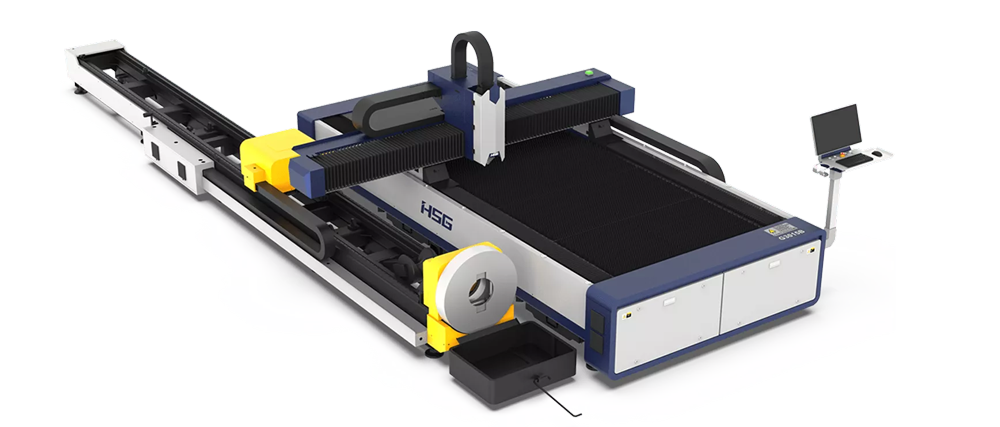

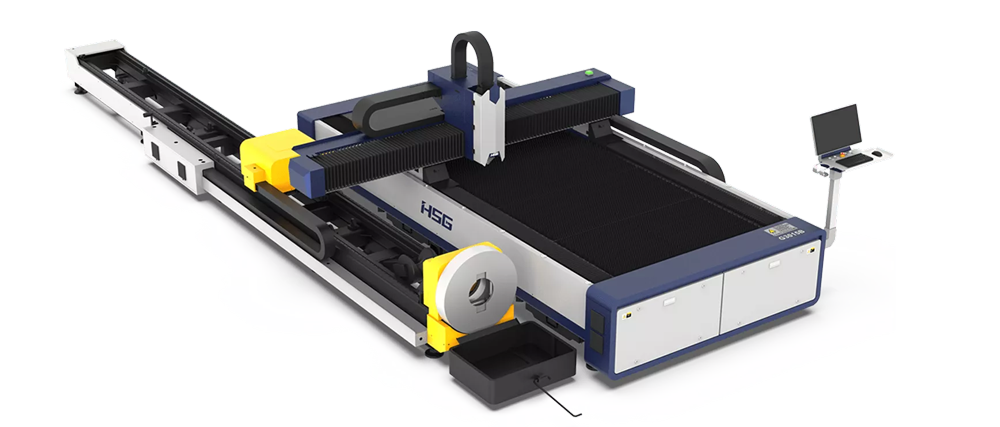

HSG’s combo sheet and tube lasers are built to handle both flat sheet metal and tubular materials with speed, precision, and minimal setup. Whether cutting standard sheets or complex tube profiles, these machines offer seamless format switching, intelligent software, and unmatched cutting performance.

Designed for efficiency and flexibility, HSG combo lasers offer high precision cutting for both sheet metal and tubing in one compact system. They handle materials like mild steel, stainless, and aluminum with clean edges and tight tolerances. Ideal for fabricators and OEMs, these machines streamline production, reduce changeovers, and maximize floor space. With automated transitions and intelligent controls, they deliver consistent results across diverse manufacturing needs.

Dual-Purpose Efficiency. One Powerful Platform.

Alpha A CNC System

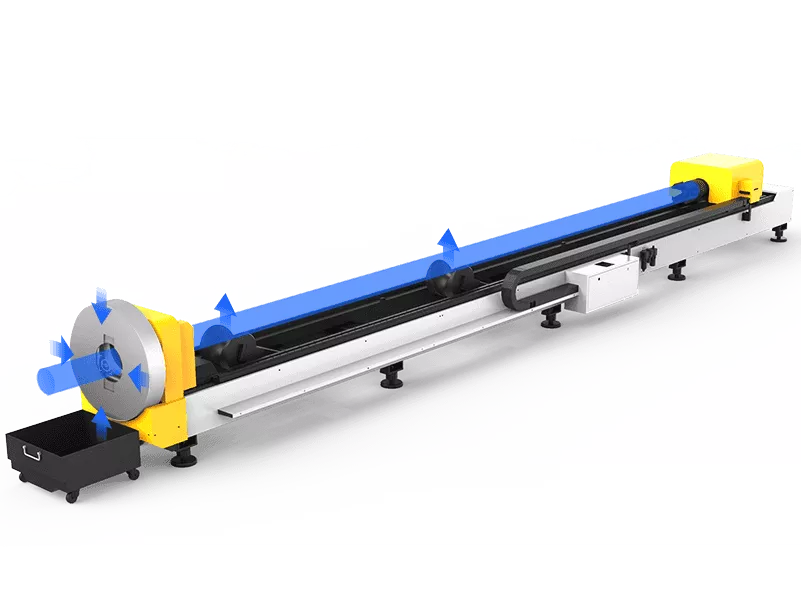

210 mm Large-Caliber Heavy-Duty Pneumatic Chuck

Integrated Cutting Capabilities

Advanced Automation & Efficiency

Easy-to-Operate Control Systems

Robust Construction & Safety

Click the dropdowns below to view detailed specifications for the Sheet & Tube Lasers.

Specification | Metric | Imperial |

Laser Power | 3kW – 6kW | 3000W – 6000W |

Machining Area (Plate) | 3048mm x 1524mm | 120 in x 60 in |

Tube Processing Range | Round Pipe:20mm – 210mm Square Tube:20mm x 20mm – 150mm x 150mm Rectangle Tube:20mm x 20mm≤each side and Diagonal≤210mm L shape:20mm x 20mm≤each side≤140mm x 140mm | Round Pipe:0.79in x 0.79in Square Tube:0.79in x 0.79in – 5.91in x 5.91in Rectangle Tube:0.79in x 0.79in ≤each side and Diagonal≤8.27in L shape:0.79in x 0.79in≤each side≤5.51in x 5.51 in |

Range of Incoming Materials for Tube | 1000mm-6000mm | 39.37in – 236.22in |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.0012 in |

Max Linkage Speed | 60m/min | 196.85 ft/min |

Max Linkage Acceleration | 0.5G | |

Max Loading Weight (Plate) | About 800kg | About 1764lb |

Max Loading Weight (Tube) | About 100kg | About 220lb |

Core Attribute | Dual Pallet Exchange System: Features a two-table design for continuous cutting and improved workflow efficiency | |

A: HSG combo lasers cut carbon steel, stainless steel, aluminum, brass, and copper — in both sheet and tube form. Machines are optimized for high-precision, multi-format cutting using fiber laser technology.

A: HSG combo lasers typically handle tube diameters from φ20 mm up to φ220 mm, depending on the model. Square, round, rectangular, oval, and some custom profiles are supported. Larger diameter handling is available with specific upgrades.

A: No. HSG combo machines are designed for fast transitions between sheet and tube modes. With automatic clamping and smart software control, the machine detects and switches between cutting types with minimal manual adjustment.

A: Not at all. HSG uses independent control systems and precision components (linear motors, bus-controlled heads) that maintain tight tolerances across both formats. Both sheet and tube cuts are equally clean and consistent.

A: Yes — HSG combo machines support “0 tailing” cutting on tube with intelligent clamping and synchronized chuck control, maximizing material usage and minimizing waste.

A: HSG combo lasers are low-maintenance and cost-efficient. Fiber laser tech means fewer consumables, lower energy use, and less downtime. Built-in diagnostics help plan service before issues arise. Shared components streamline upkeep, and routine tasks like lens cleaning or filter changes are quick and easy. Overall, it’s more affordable to run than two separate machines.

A: No — combo systems use the same HSG-X BUS CNC interface, which is easy to learn and designed to simplify dual-function operation. Operators can quickly switch between jobs with just a few taps on the screen.

A: HSG combo machines support standard sheet formats like 3000×1500 mm (5’×10’), with options for larger formats depending on the model (e.g. 4000×2000 mm). Cutting area doesn’t compromise tube capabilities.

A: Not at all. HSG machines are designed with dual-purpose efficiency in mind. Dedicated tube fixtures and optimized cutting paths keep cycle times low, even when switching between formats.

A: Not at all. HSG machines are designed with dual-purpose efficiency in mind. Dedicated tube fixtures and optimized cutting paths keep cycle times low, even when switching between formats.

A: Not at all. HSG machines are designed with dual-purpose efficiency in mind. Dedicated tube fixtures and optimized cutting paths keep cycle times low, even when switching between formats.

A: An HSG combo machine is cost-effective, space-saving, and ideal for shops handling mixed workloads. It provides flexibility without sacrificing quality, making it perfect for custom fabricators, small OEMs, and high-mix job shops.