R Series Laser Cutting Machines from HSG Laser offer powerful, efficient solutions for tube processing, featuring intelligent systems for precise cutting, automation, and productivity enhancement.

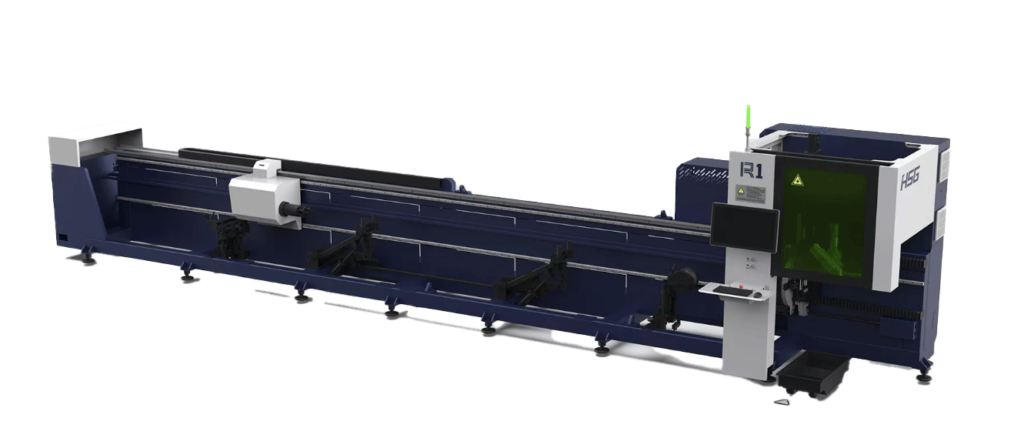

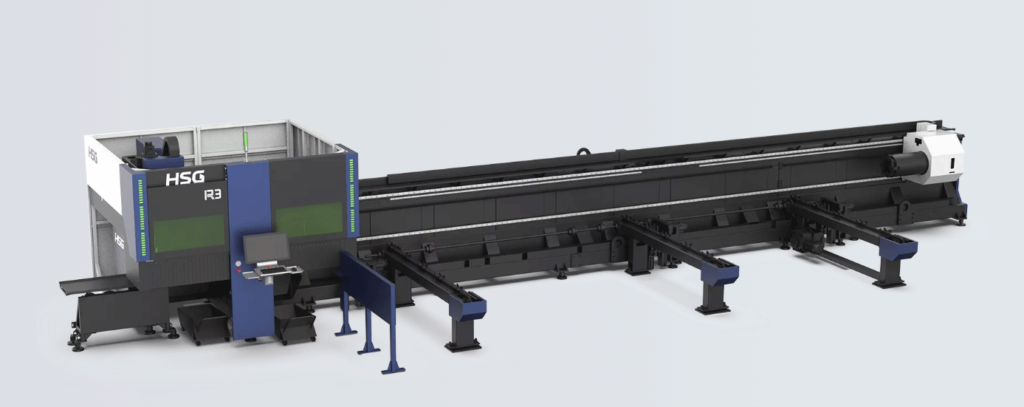

The R Series from HSG Laser is a high-performance line of tube laser cutting machines designed for fast, precise, and automated pipe processing. Ideal for industries requiring complex profiles and batch efficiency, the R Series integrates intelligent clamping systems, full-stroke pneumatic chucks, and automated loading to streamline workflow and reduce labor costs. With models like R1, R2, and R3/R, it meets varying demands across tube sizes and cutting complexity.

The HSG R Series offers full-stroke pneumatic chucks for steady tube holding, auto-centering, and high-speed rotation. Its intelligent clamping ensures precision across various profiles. With automated loading/unloading and support for round, square, and special-shaped pipes, it boosts efficiency in mass production. Integrated CNC control enhances cutting accuracy and user operation.

Choosing the R Series ensures precise, stable cutting of tubes and pipes, reducing waste and boosting productivity. Its automation capabilities lower labor intensity, while advanced control systems offer consistent high-speed performance across diverse industrial applications.

Click the dropdowns below to view detailed specifications for the R Series.

Specification | Metric | Imperial |

Laser Power | 1.5kW – 6kW | 1500W – 6000W |

Tube Processing Range | R1 Round tube: 8mm – 120mm Square tube: 8mm x 8mm – 120mm x 120mm Side Length: 8mm – 120mm R2 Round tube: 8mm – 240mm Square tube: 8mm x 8mm – 240mm x 240mm Side Length: 8-240mm R3 Round tube: 20mm – 325mm Square tube: 20mm x 20mm – 230mm x 230mm Diagonal≤325mm | R1 Round tube: 0.31in- 4.72in Square tube: 0.31in x 0.31in – 4.72in x 4.72in Side Length: 0.31in – 4.72in R2 Round tube: 0.31in- 9.45in Square tube: 0.31in x 0.31in – 9.45in x 9.45in Side Length: 0.31in – 9.45in R3 Round tube: 0.79in – 12.80in Square tube: 0.79in x 0.79in – 9.06in x 9.06in Diagonal≤12.80in |

Range of Incoming Materials for Tube | 1000mm – 6500mm | 39.37in – 255.91in |

Positioning Precision of X/Y Axis | ±0.05mm/m | ±0.00059in/ft |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.0012mm |

Speed of Chuck | 150 RPM (R1) 100 RPM (R2) 90 RPM(R3) | |

Max Linkage Speed | 150 m/min (R1) 120 m/min (R2) 90 m/min (R3) | 492ft/min (R1) 393.7ft/min (R2) 295.28ft/min (R3) |

Max Linkage Acceleration | 1.5 G (R1) 1.0 G (R2) 0.8 G (R3) | |

Max Single Tube Weight | About 50 kg (R1) About 300kg (R2) About 200kg (R3) | About 110lb (R1) About 661lb (R2) About 441lb (R3) |

Bevel Option | No | |

Core Attributes | R1 Compact, High-Speed Tube Laser Cutter: Tailored for precision work on small-diameter tubes Real-Time Tube Support: Adaptive follow-up support ensures stable, accurate cutting Smart Bus-Controlled Operation: Delivers responsive performance and intuitive system management R2 Versatile Dual-Chuck Tube Laser Cutter: Engineered for a wide range of pipe and profile shapes Standard Rectangular & Circular Chuck Setup: Handles multiple tube geometries with ease Smooth, High-Speed Motion Control: Enhanced dynamics enable faster cycles and increased throughput R3 Cost-Effective Tube Laser Cutting Solution: Efficient performance in a compact footprint Space-Saving Design: Small form factor ideal for workshops with limited floor space Pneumatic Chuck System: One-click opening with automatic centering for faster setup Double-Row Roller Clamping: Provides stable holding force to maintain cutting accuracy | |

A: The R Series can cut round, square, rectangular, and various special-shaped tubes, accommodating diverse industrial needs.

A: The R Series supports automatic loading and unloading, intelligent clamping, and quick profile switching to enhance production efficiency.

A: It uses CNC systems, full-stroke pneumatic chucks, and auto-centering clamps to maintain high cutting accuracy.

A: It’s ideal for furniture, automotive, fitness equipment, agricultural machinery, and construction pipe fabrication.

A: Each model supports different tube diameters and lengths, with R3/R offering optional bevel cutting and expanded automation for advanced processing tasks.