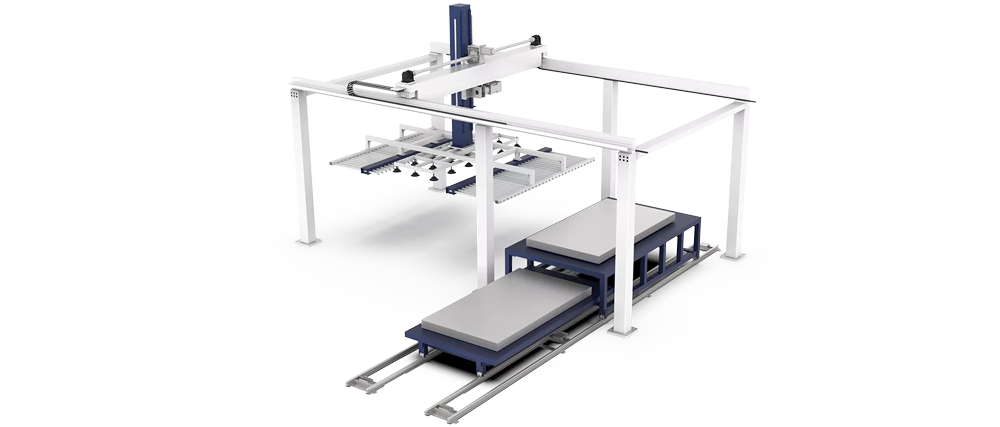

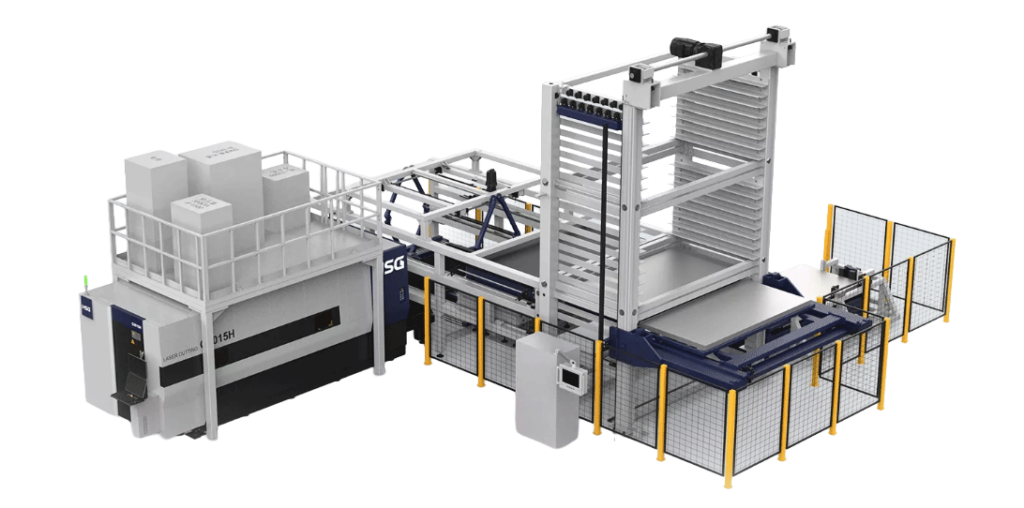

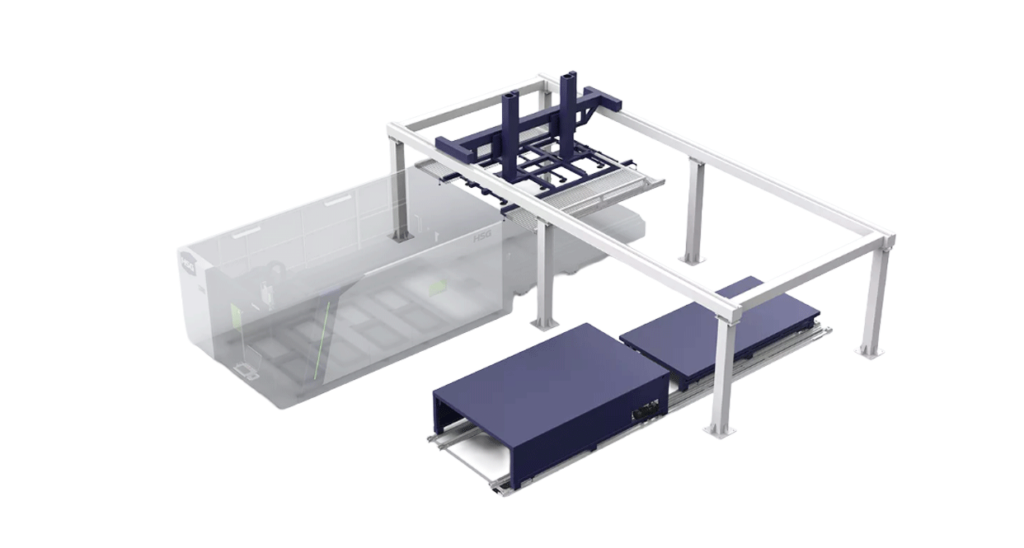

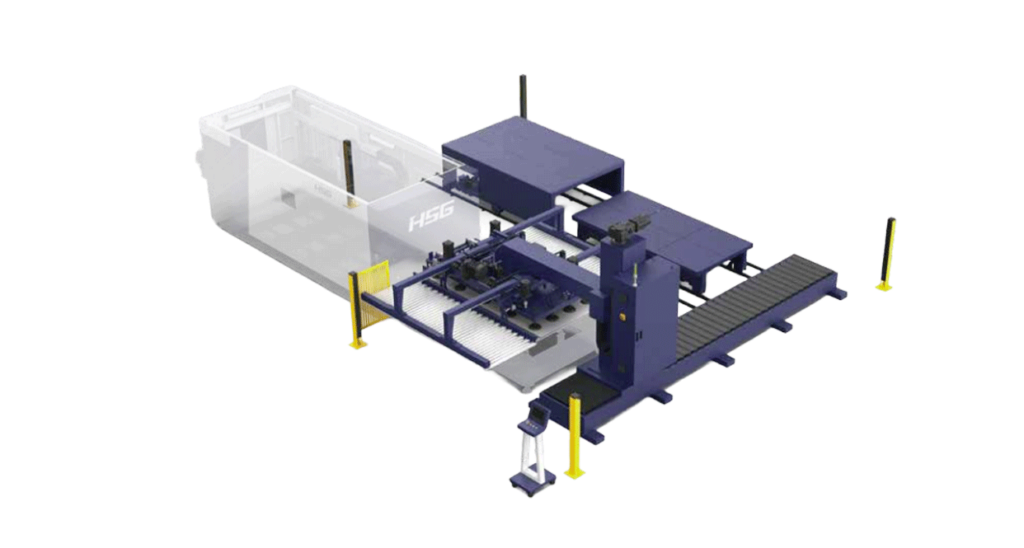

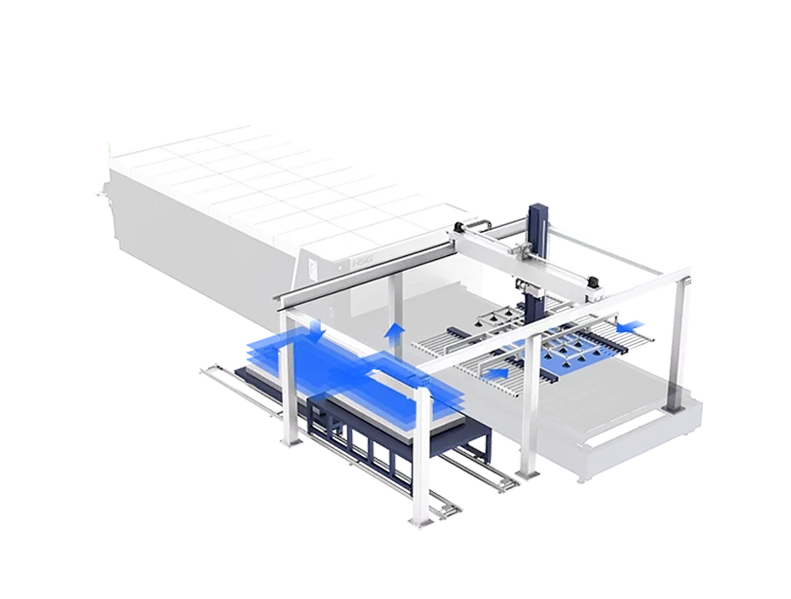

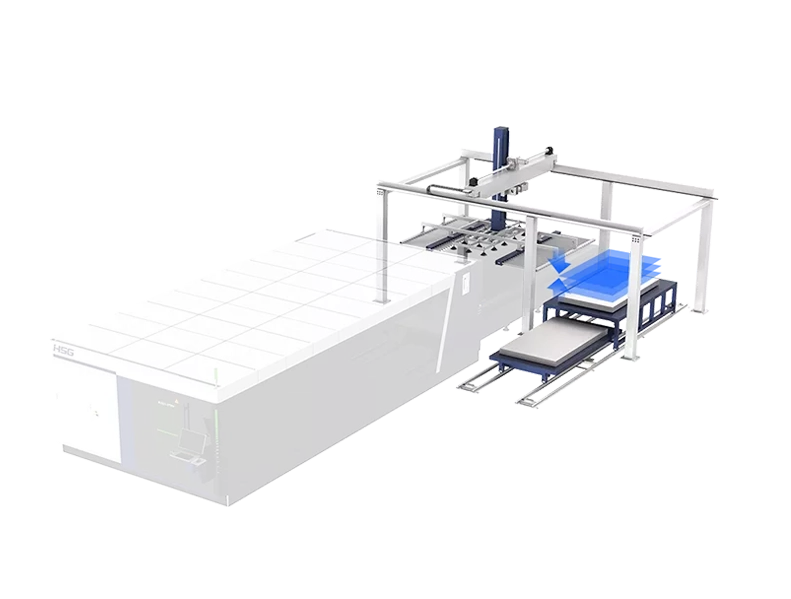

HSG Automation Equipment is engineered to optimize the entire fabrication workflow — from material handling and loading to part sorting and storage. Designed to integrate seamlessly with HSG cutting systems, these automation solutions reduce labor, improve uptime, and support smart factory goals.