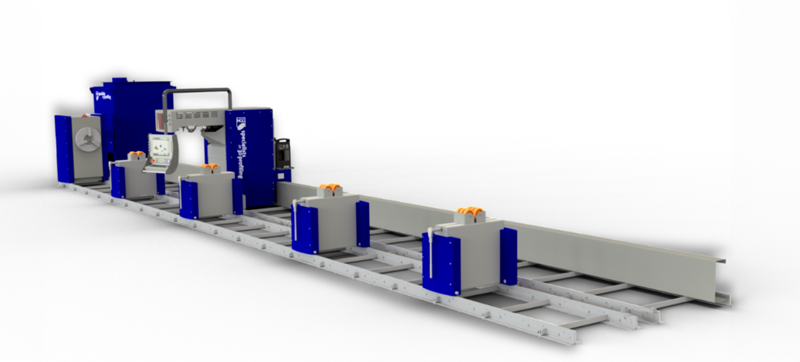

The ProCutter Series by HGG Group is a high-performance, all-in-one cutting solution designed to simplify and optimize pipe, beam, and profile processing. Known for precision and efficiency, it is tailored for industries requiring complex cutting with minimal waste and maximum speed.

The ProCutter Series from HGG Group sets the standard for cutting-edge pipe, beam, and profile cutting solutions. Designed for industries such as construction, shipbuilding, and offshore, it delivers unmatched precision and efficiency. Its advanced automation, versatility, and accuracy redefine productivity in steel fabrication, saving time and reducing material waste.

The ProCutter Series excels with advanced 3D profiling technology, enabling accurate cuts for complex geometries. Its user-friendly interface streamlines operation, while robust automation minimizes human error. Offering superior speed and precision, this series supports various materials and profiles, meeting diverse industrial demands seamlessly.

Choosing the ProCutter Series means benefiting from increased efficiency, reduced waste, and enhanced productivity. Its ability to handle intricate cuts with precision ensures high-quality results. The automation minimizes operational costs and human error, making it an invaluable asset for modern steel fabrication processes.

Click the dropdowns below to view detailed specifications for the ProCutter Series.

| ProCutter 600 – 900 Specifications | |

|---|---|

| Profile Diameter Range | 48 mm – 910 mm (1.89 in – 35.83 in) |

| Cutting Processes | Oxy-fuel, Plasma |

| Marking Options | Plasma marking with cutting torch |

| Plasma Power Source | Hypertherm or Kjellberg |

| Maximum Cutting Angle | 45 degrees |

| CAD Connection | Compatible with various CAD software |

| ProCutter 900 RB Specifications | |

|---|---|

| Profile Diameter Range | 48 mm – 914 mm (1.89 in – 36 in) |

| Cutting Process | Plasma |

| Marking Options | Plasma marking with cutting torch |

| Plasma Power Source | Hypertherm or Kjellberg |

| Maximum Cutting Angle | 45 degrees |

| CAD Connection | Compatible with various CAD software |

A: The ProCutter Series is designed to cut steel, stainless steel, and other alloys with high precision.

A: It serves industries like construction, shipbuilding, offshore, and industrial fabrication.

A: Its advanced automation and precision reduce material waste and operational errors, boosting efficiency.

A: Yes, its 3D profiling technology ensures accurate cuts for intricate designs and geometries.

A: Absolutely. The user-friendly interface simplifies operation, ensuring smooth integration into workflows.