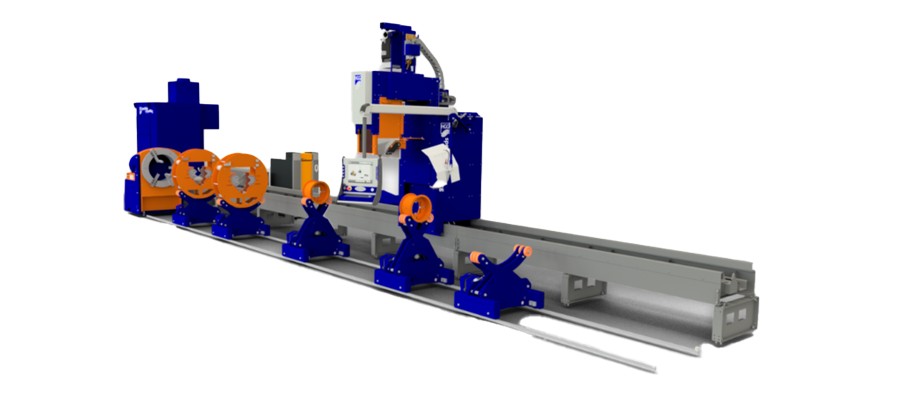

The MPC 450 | 500 – 1200 by HGG Group offers advanced, multi-dimensional profiling capabilities for metal fabrication. Designed for precision and efficiency, it transforms cutting processes across industries.

The MPC 450 | 500 – 1200 is a robust cutting solution in the steel fabrication industry. Known for its versatility, it handles diverse materials and shapes, including pipes, beams, and profiles. Its innovative design supports automation, enhancing productivity and accuracy for complex projects.

This cutting-edge machine delivers exceptional profiling accuracy for diverse materials. Key features include 3D cutting, a user-friendly interface, and automation capabilities. Its flexibility makes it ideal for pipe and beam processing, supporting diverse industries such as construction and shipbuilding.

Choose the MPC 450 | 500 – 1200 for precision, efficiency, and versatility in metal fabrication. It reduces manual labor, increases project accuracy, and enhances productivity, making it a trusted asset in demanding fabrication environments.

Click the dropdowns below to view detailed specifications for the MPC 450 | 500 – 1200.

| Feature | Specification |

|---|---|

| Machine Type | Multiple Profile Cutting Machine |

| Profiles Supported | Pipes, Box Sections, Flat Bars |

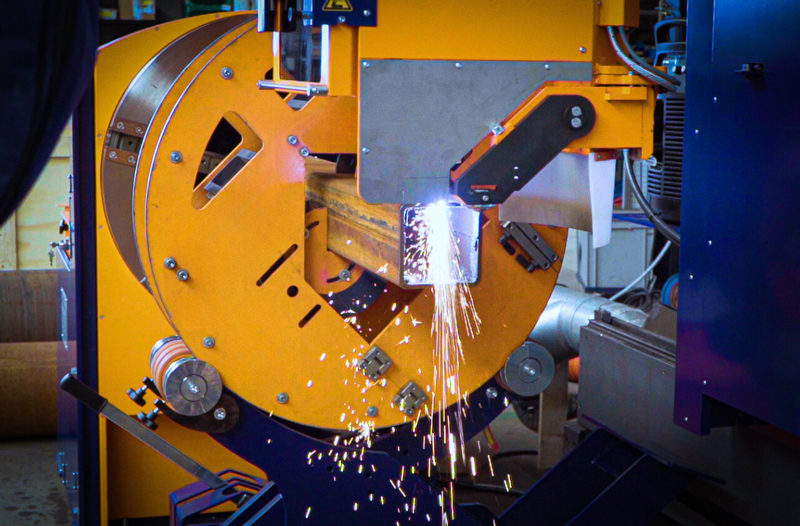

| Cutting Processes | Oxyfuel, Plasma |

| Industries | Shipbuilding, Offshore, Process Piping |

| Switching Time Between Profiles | Minutes |

| Measurement System | 3D Laser Measurement |

| Weld Preparations | X- and K-bevels with Transition Zones |

| Profile Diameter Range | 2 to 48 inches |

A: It’s ideal for industries such as construction, shipbuilding, and offshore fabrication.

A: It handles various materials, including pipes, beams, and structural profiles.

A: Yes, it supports automation, reducing manual intervention and improving efficiency.

A: The 3D cutting technology ensures precise and accurate profiling for complex designs.

A: The MPC 450 | 500 – 1200 combines speed, flexibility, and accuracy, making it superior to conventional methods.