Material Handling from HE&M Saw enhances efficiency, safety, and productivity in industrial environments. Designed with precision engineering, these systems ensure optimal support and movement of materials during cutting processes.

Material Handling from HE&M Saw enhances efficiency, safety, and productivity in industrial environments. Designed with precision engineering, these systems ensure optimal support and movement of materials during cutting processes.

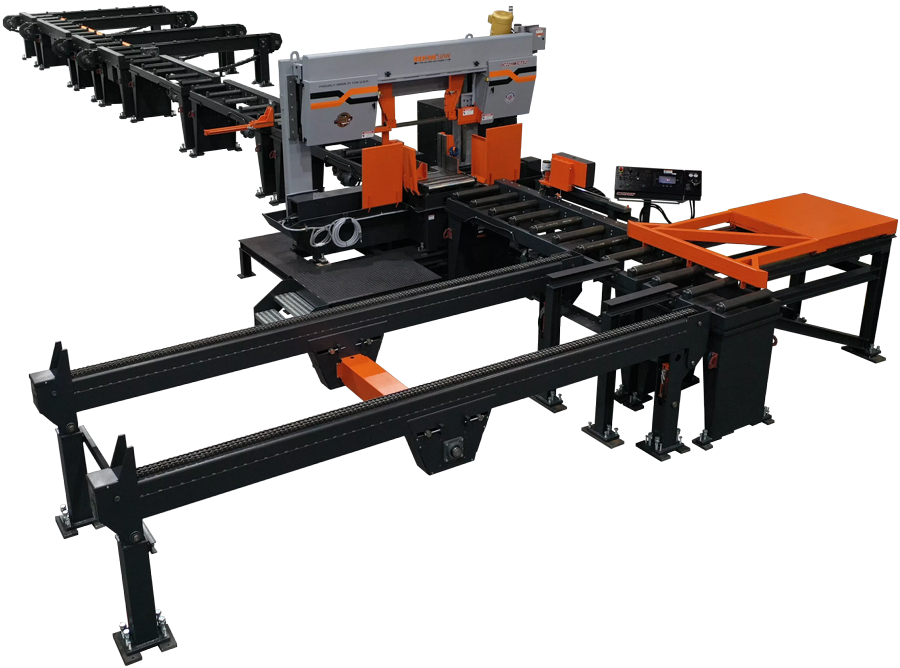

Material handling solutions are vital for streamlining workflows in industrial settings. HE&M Saw provides robust systems to support material transportation, positioning, and storage, ensuring smooth integration with saw operations. These solutions are engineered to improve cutting precision, minimize downtime, and maximize efficiency.

HE&M Saw material handling systems offer durability, precision, and adaptability. Their modular designs support custom configurations to meet diverse operational needs. Key features include conveyor systems, adjustable tables, and automated feeding options, ensuring seamless integration with sawing equipment and optimized workflow.

Choosing HE&M Saw material handling solutions ensures increased productivity, reduced manual labor, and enhanced workplace safety. These systems reduce material handling time, improve accuracy, and extend equipment longevity, offering significant value for industrial operations.

Click the dropdowns below to view detailed specifications for the Material Handling.

| Feature | Description |

|---|---|

| Stages | 4 Stages of Conveyor Tables |

| Design | Modular design for custom configurations |

| Integration | Seamless integration with sawing equipment |

| Durability | Built to withstand heavy loads |

| Feature | Description |

|---|---|

| Type | Continuous Chain or Lift & Carry |

| Function | Efficient lateral movement of materials |

| Customization | Adaptable to various material sizes and weights |

| Integration | Compatible with existing conveyor systems |

| Feature | Description |

|---|---|

| Function | Facilitates loading, unloading, and storage of materials |

| Design | Robust construction for heavy-duty operations |

| Integration | Works seamlessly with conveyor and saw systems |

| Safety | Enhances workplace safety by reducing manual handling |

| Feature | Description |

|---|---|

| Type | Contact and Non-Contact options available |

| Accuracy | High-precision measurement for quality control |

| Integration | Compatible with material handling and sawing equipment |

| Application | Suitable for various material types and sizes |

| Feature | Description |

|---|---|

| Purpose | Customized solutions for unique material handling needs |

| Monitoring | Real-time system monitoring for enhanced productivity |

| Integration | Designed to work with existing systems |

| Support | Backed by HE&M Saw’s engineering expertise |

A: HE&M Saw material handling systems are designed to facilitate the movement, positioning, and support of materials during sawing operations, improving efficiency and accuracy.

A: Yes, HE&M Saw offers modular systems that can be tailored to specific operational needs, including conveyor lengths and table configurations.

A: HE&M Saw material handling solutions are designed for seamless integration with their range of saws, ensuring optimal performance.

A: By automating material transport and positioning, these systems reduce manual handling, minimizing the risk of workplace injuries.

A: Industries like manufacturing, construction, and metal fabrication benefit greatly from HE&M Saw’s efficient and reliable material handling systems.