HARMO America’s Gran Cutters efficiently recycle sprues and runners into uniform granules, reducing waste, minimizing dust, and delivering high-quality material for sustainable injection molding operations.

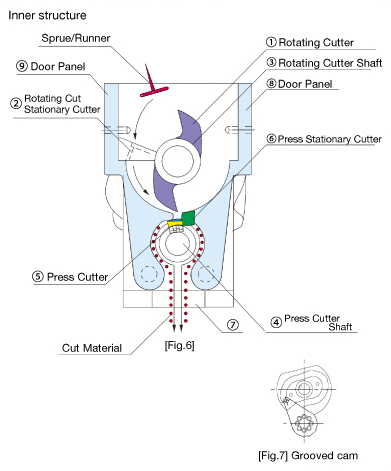

HARMO America’s Gran Cutters are advanced re-pelleting machines designed to recycle runners and sprues into uniform granules comparable to virgin material size. With a patented swing press cutting system, these cutters significantly improve material recycling efficiency in injection molding operations, reducing waste while promoting sustainability and cost-effectiveness in production environments.

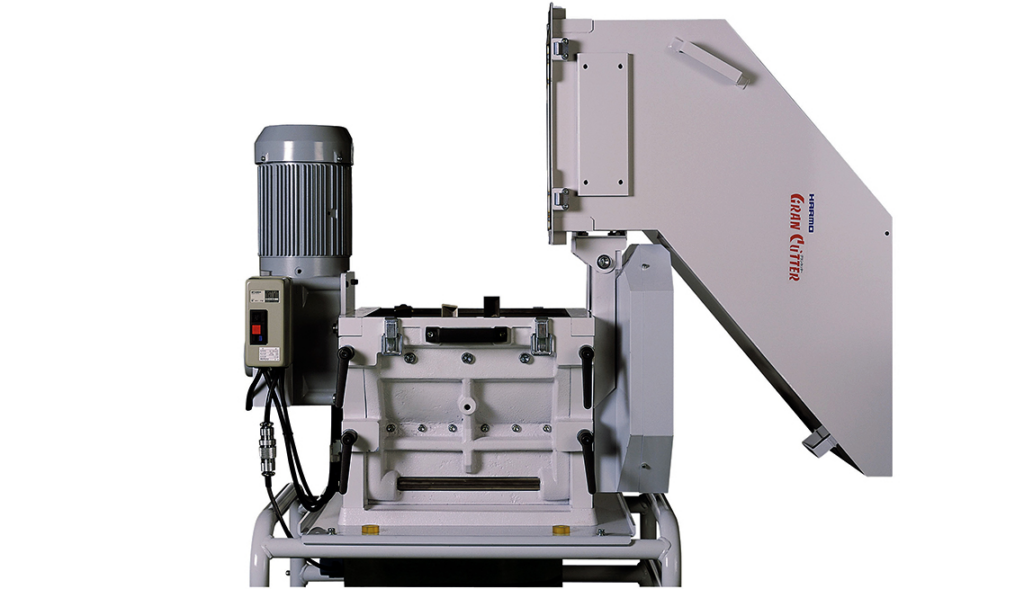

HARMO’s Gran Cutters provide innovative features that optimize performance and reliability. The unique cutting mechanism ensures clean cuts without repeated impact, minimizing dust, heat buildup, and static electricity. Granules produced are consistent in size, comparable to virgin pellets, without requiring screens or secondary processing. The machines operate quietly, enhancing the production environment, and include wide-access doors for fast, easy cleaning. These features collectively improve operational efficiency and material quality.

Choosing HARMO America’s Gran Cutters allows manufacturers to efficiently recycle plastic sprues and runners, reducing material costs and minimizing waste. The precision cutting mechanism ensures uniform re-pelleted material suitable for reuse in production lines. Quiet operation and user-friendly design streamline workflows while minimizing downtime, making Gran Cutters an essential tool for sustainable and cost-effective injection molding operations.

Click the dropdowns below to view detailed specifications for each Gran Cutter

| Specification | Value |

|---|---|

| Place of Operation | Indoor |

| Ambient Temperature Range | -10°C to +40°C |

| Ambient Humidity | Up to 85% |

| Power Input | 3-phase AC 200V (50Hz/60Hz) |

| Motor | Geared motor, 0.2 kW-4P |

| Rotary Cutter | Diameter: 98 mm; Quantity: 4; Speed: 37.5 rpm (50Hz) / 45 rpm (60Hz) |

| Press Moving Cutter | Dimensions: 2.1 mm x 3.5 mm; Quantity: 24; Cycles: 75/min (50Hz) / 90/min (60Hz) |

| Mouth on Main Body | 120 mm x 120 mm |

| Hopper Throat | 120 mm x 120 mm |

| Material Tank Volume | 6 liters (approximately 3 kg) |

| Maximum Sprue Diameter for Cutting | Up to 6 mm |

| Processing Capacity | 30–40 g/min (intermittent feeding) |

| Machine Weight | 60 kg |

| Specification | Value |

|---|---|

| Place of Operation | Indoor |

| Ambient Temperature Range | -10°C to +40°C |

| Ambient Humidity | Up to 85% |

| Power Input | 3-phase AC 200V (50Hz/60Hz) |

| Motor | Geared motor, 0.2 kW-4P |

| Rotary Cutter | Diameter: 98 mm; Quantity: 4; Speed: 37.5 rpm (50Hz) / 45 rpm (60Hz) |

| Press Moving Cutter | Dimensions: 2.1 mm x 3.5 mm; Quantity: 24; Cycles: 75/min (50Hz) / 90/min (60Hz) |

| Mouth on Main Body | 120 mm x 120 mm |

| Hopper Throat | 120 mm x 120 mm |

| Material Tank Volume | 6 liters (approximately 3 kg) |

| Maximum Sprue Diameter for Cutting | Up to 6 mm |

| Processing Capacity | 30–40 g/min (intermittent feeding) |

| Machine Weight | 60 kg |

| Specification | Value |

|---|---|

| Place of Operation | Indoor |

| Ambient Temperature Range | -10°C to +40°C |

| Ambient Humidity | Up to 85% |

| Power Input | 3-phase AC 200V (50Hz/60Hz) |

| Motor | Geared motor, 1.5 kW-3P, grounded |

| Rotary Cutter | Diameter: 220 mm; Quantity: 4; Blade thickness: 30 mm; Speed: 37.5 rpm (50Hz) / 45 rpm (60Hz) |

| Press Moving Cutter | Dimensions: 3.8 mm x 6 mm; Quantity: 45; Cycles: 112.5/min (50Hz) / 135/min (60Hz) |

| Hopper Mouth | 402 mm x 360 mm |

| Maximum Sprue Diameter for Cutting | Up to 13 mm |

| Processing Capacity | 320–400 g/min (intermittent feeding) |

| Capacity of Suction Tank | Approximately 9 liters (4 kg) |

| Machine Weight | 295 kg |

| Specification | GMII-200t | GMII-200St |

|---|---|---|

| Power Supply | 3-phase AC 200V (50/60Hz) | 3-phase AC 200V (50/60Hz) |

| Motor Output | 0.2 kW, grounded 4P | 0.2 kW, grounded 4P |

| Rotary Cutter Diameter | Ø98 mm | Ø98 mm |

| Rotary Cutter Quantity | 4 | 4 |

| Rotary Cutter Speed | 37.5 rpm (50Hz) / 45 rpm (60Hz) | 37.5 rpm (50Hz) / 45 rpm (60Hz) |

| Press Moving Cutter Dimensions | 2.1 mm × 3.5 mm | 2.1 mm × 3.5 mm |

| Press Moving Cutter Quantity | 24 | 24 |

| Press Moving Cutter Cycles | 75 cycles/min (50Hz) / 90 cycles/min (60Hz) | 75 cycles/min (50Hz) / 90 cycles/min (60Hz) |

| Hopper Mouth Dimensions | 120 mm × 120 mm | 120 mm × 120 mm |

| Maximum Sprue Diameter | Up to 6 mm | Up to 6 mm |

| Processing Capacity | 30–40 g/min (intermittent feeding) | 30–40 g/min (intermittent feeding) |

| Material Tank Capacity | Approximately 25 kg | Approximately 25 kg |

| Granule Tank Capacity | Approximately 4.0 kg | Approximately 4.0 kg |

| Mixing Tank Capacity | Approximately 3.5 kg | Approximately 3.5 kg |

| Machine Weight | 109 kg | 114 kg |

| Specification | GMII-200t | GMII-200St |

|---|---|---|

| Power Supply | 3-phase AC 200V (50/60Hz) | 3-phase AC 200V (50/60Hz) |

| Motor Output | 0.2 kW, grounded 4P | 0.2 kW, grounded 4P |

| Rotary Cutter Diameter | Ø98 mm | Ø98 mm |

| Rotary Cutter Quantity | 4 | 4 |

| Rotary Cutter Speed | 37.5 rpm (50Hz) / 45 rpm (60Hz) | 37.5 rpm (50Hz) / 45 rpm (60Hz) |

| Press Moving Cutter Dimensions | 2.1 mm × 3.5 mm | 2.1 mm × 3.5 mm |

| Press Moving Cutter Quantity | 24 | 24 |

| Press Moving Cutter Cycles | 75 cycles/min (50Hz) / 90 cycles/min (60Hz) | 75 cycles/min (50Hz) / 90 cycles/min (60Hz) |

| Hopper Mouth Dimensions | 120 mm × 120 mm | 120 mm × 120 mm |

| Maximum Sprue Diameter | Up to 6 mm | Up to 6 mm |

| Processing Capacity | 30–40 g/min (intermittent feeding) | 30–40 g/min (intermittent feeding) |

| Material Tank Capacity | Approximately 25 kg | Approximately 25 kg |

| Granule Tank Capacity | Approximately 4.0 kg | Approximately 4.0 kg |

| Mixing Tank Capacity | Approximately 3.5 kg | Approximately 3.5 kg |

| Machine Weight | 109 kg | 114 kg |

| Specification | GMII-750t | GMII-750St |

|---|---|---|

| Power Supply | 3-phase AC 200V (50/60Hz) | 3-phase AC 200V (50/60Hz) |

| Motor Output | 0.75 kW, grounded 4P | 0.75 kW, grounded 4P |

| Rotary Cutter Diameter | Ø176 mm | Ø176 mm |

| Rotary Cutter Quantity | 4 | 4 |

| Rotary Cutter Speed | 37.5 rpm (50Hz) / 45 rpm (60Hz) | 37.5 rpm (50Hz) / 45 rpm (60Hz) |

| Press Moving Cutter Dimensions | 2.8 mm × 4.5 mm | 2.8 mm × 4.5 mm |

| Press Moving Cutter Quantity | 41 | 41 |

| Press Moving Cutter Cycles | 112.5 cycles/min (50Hz) / 135 cycles/min (60Hz) | 112.5 cycles/min (50Hz) / 135 cycles/min (60Hz) |

| Hopper Mouth Dimensions | 246 mm × 285 mm | 246 mm × 285 mm |

| Maximum Sprue Diameter | Up to 10 mm | Up to 10 mm |

| Processing Capacity | 320–400 g/min (intermittent feeding) | 320–400 g/min (intermittent feeding) |

| Material Tank Capacity | Approximately 25 kg | Approximately 25 kg |

| Granule Tank Capacity | Approximately 4.0 kg | Approximately 4.0 kg |

| Mixing Tank Capacity | Approximately 3.5 kg | Approximately 3.5 kg |

| Machine Weight | 180 kg | 180 kg |

A: HARMO’s Gran Cutters can handle both hard plastics like PMMA and POM and softer materials such as PP, PE, TPE, and PUR, making them highly versatile for various applications.

A: The patented swing press cutting system prevents repeated cuts on the same material, minimizing dust generation, static buildup, and heat, resulting in cleaner, higher-quality granules.

A: Yes, HARMO provides specialized models like the S-Type Gran Cutter, specifically designed to process soft-type resins effectively while maintaining precision and efficiency.

A: Gran Cutters feature wide-opening doors for easy cleaning, typically requiring only 5 to 7 minutes for maintenance. The design also minimizes dust adherence, reducing cleanup time further.

A: Unlike conventional granulators, Gran Cutters use a unique swing press cutting system that produces uniform granules, reduces dust, and operates quietly, ensuring high efficiency and superior output quality.