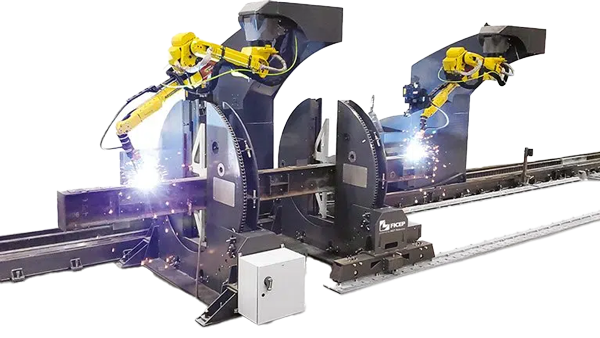

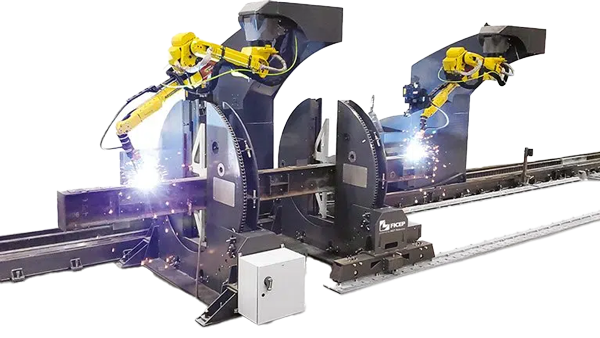

FICEP Corporation offers advanced robotic welding systems designed to revolutionize industrial automation. Their solutions ensure precision, efficiency, and high-quality results for modern manufacturing needs.

FICEP Corporation offers advanced robotic welding systems designed to revolutionize industrial automation. Their solutions ensure precision, efficiency, and high-quality results for modern manufacturing needs.

Robotic welding systems are transforming manufacturing by delivering unparalleled accuracy and efficiency. FICEP Corporation’s expertise in welding automation ensures reliable solutions that cater to diverse industrial applications, enhancing productivity and reducing costs. With FICEP’s commitment to innovation, businesses can meet the demands of a competitive market while maintaining superior quality.

FICEP robotic welding systems incorporate state-of-the-art technology, enabling precise welds on various materials. Key features include adaptive welding, integrated sensors, and customizable programming. These systems streamline operations, reduce manual intervention, and enhance production rates. Designed for flexibility, they address diverse industry needs with unmatched efficiency.

FICEP robotic welding delivers consistent quality, increased productivity, and lower labor costs. These systems minimize errors and material wastage while ensuring scalability for future demands. By automating welding tasks, businesses can optimize operations and remain competitive in dynamic industries.

Click the dropdowns below to view detailed specifications for the Robotic Welding.

| SABRE Automatic Welding Robot | |

|---|---|

| Function | Robotic welding of secondary components on main structural members |

| Welding Positioners | Automated positioners to hold and rotate sections during welding |

| Detail Item Probing | Automatic sensing of tacked detail items before welding |

| Section Compatibility | Beams, angles, flats |

| Automation Level | Eliminates manual layout; automates welding processes |

| Productivity | Matches output of 6-8 manual workers |

| Software Integration | Interfaces with CAD data for automatic welding path generation |

| E-LEXINGTON Laser Projector for Robotic Welding | |

|---|---|

| Function | Laser projection for layout in robotic welding |

| Laser Profile Identification | Locates section and zero point for layout projection |

| Detail Item Projection | Projects layout locations on main member for detail items |

| Section Compatibility | Beams, angles, flats |

| Automation Level | Eliminates manual layout; automates projection processes |

| Software Integration | Accepts CAD data for accurate projection without manual manipulation |

A: FICEP’s robotic welding systems are ideal for industries like construction, automotive, aerospace, and heavy machinery manufacturing.

A: Robotic welding automates tasks, ensuring faster production cycles, consistent quality, and reduced downtime.

A: Yes, FICEP’s systems are highly customizable to meet specific operational and material requirements.

A: Absolutely. FICEP robotic welding systems are equipped with advanced programming and adaptive technologies to handle intricate welding operations.

A:FICEP robotic welding systems are designed for durability and require minimal, scheduled maintenance to ensure optimal performance.