Efficiently process angles and flats with FICEP Corporation’s innovative solutions. Designed for precision and productivity, these machines excel in manufacturing efficiency across various industries.

Efficiently process angles and flats with FICEP Corporation’s innovative solutions. Designed for precision and productivity, these machines excel in manufacturing efficiency across various industries.

Angles and flats are integral in structural engineering and manufacturing. FICEP Corporation’s innovative solutions streamline processing, making production more efficient and cost-effective. These advanced machines ensure precision cutting, drilling, and marking, catering to diverse industries like construction, shipbuilding, and energy sectors.

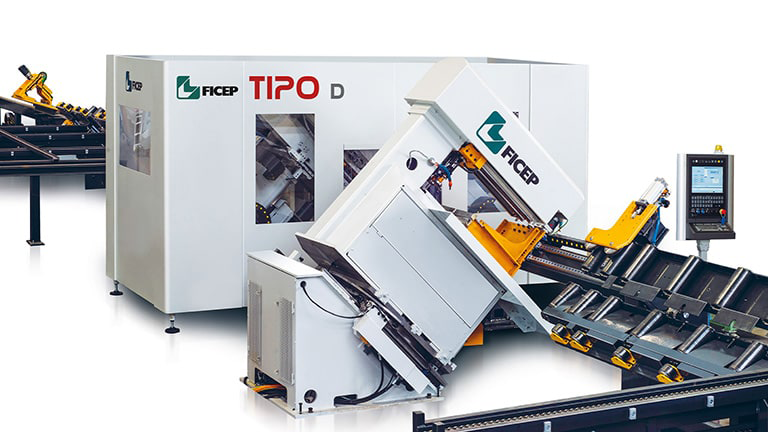

FICEP Corporation’s angles and flats processing systems feature advanced automation for cutting, drilling, and marking. With unmatched precision and speed, these machines maximize output and minimize waste. Modular designs accommodate varied production needs, ensuring seamless integration into existing workflows and boosting overall productivity.

Choosing FICEP Corporation’s angles and flats solutions enhances efficiency, reduces production time, and improves product quality. These systems deliver a high return on investment through optimized material utilization and streamlined operations, making them an indispensable asset for competitive industries.

Click the dropdowns below to view detailed specifications for the Angles & Flats.

| Specification | Details |

|---|---|

| Processing Capabilities | Punching, Notching, Shearing, Marking |

| Material Types | Angles, Flats, Channels |

| Punching Units | 1, 2, or 3 per angle leg |

| Shearing Unit | Single or double cut shear with special hold-down systems |

| Material Positioning | CNC-controlled with internal roller feed drives and measuring rolls |

| Optional Features | Flat bar processing, versatile shearing for angles, flats, and channels |

| Loading System | Automatic rotating material loading system |

| Integration | Compatible with infeed and outfeed cross transfer tables for automated loading/unloading |

| Specification | Details |

|---|---|

| Processing Capabilities | Punching, Drilling, Notching, Shearing, Marking |

| Material Types | Angles, Flats, Channels |

| Punching Speed | Enhanced by high-tech hydraulic power pack; auto-adjusts based on hole diameter and material |

| Shearing Speed | Optimized by innovative hydraulic design; CNC-managed force and speed |

| Material Positioning | High-speed rack and pinion system; up to 120 m/min (395 FPM) |

| Hold-Down System | Automatic roller system for secure material clamping during positioning |

| Marking Unit | Fully programmable marking press or traditional cartridge style |

| Loading System | Automatic rotating material loading system |

| Integration | Compatible with infeed and outfeed cross transfer tables for automated loading/unloading |

| Specification | Details |

|---|---|

| Processing Capabilities | Punching, Drilling, Notching, Shearing, Marking |

| Material Types | Large Angles, Flats, Channels |

| Punching Units | 2 or 3 per angle leg; quick-change tool holders |

| Notching Unit | Integrated for generating required notches |

| Marking Unit | Fully programmable marking press or traditional cartridge style |

| Loading System | Automatic rotating material loading system |

| Integration | Compatible with infeed and outfeed cross transfer tables for automated loading/unloading |

| Specification | Details |

|---|---|

| Processing Capabilities | Drilling, Scribing, Milling, Disc Sawing, Shearing, Marking |

| Material Types | Angles, Flats, Channels |

| Drilling Units | High-speed direct drive spindles with servo-driven rack and pinion positioning |

| Tool Changer | 3 or 6 position automatic tool changer for quick replacements |

| Spindle Sub-Axis | 200 mm (7-7/8”) stroke for milling and slotting |

| Shearing Unit | Single cut shear with special hold-down systems |

| Disc Saw | Available for 90° angle cutting as standard |

| Marking Unit | Fully programmable marking press or traditional cartridge style |

| Material Feeding | High-speed carriage with pincher system for accurate positioning |

| Loading System | Automatic rotating material loading system |

| Integration | Compatible with infeed and outfeed cross transfer tables for automated loading/unloading |

| Specification | Details |

|---|---|

| Processing Capabilities | Punching, Drilling, Scribing, Shearing, Plasma Cutting, Marking |

| Material Types | Flats, Angles |

| Punching Unit | 4 or 8 stations; 1100 kN (124 US tons) force |

| Shearing Unit | Single cut shear with precision hold-down systems |

| Drilling Unit | ISO40 spindle with CNC-controlled rack-and-pinion feed |

| Tool Changer | 4-position automatic tool changer |

| Marking Unit | CNC-controlled rotating disc with alphanumeric characters |

| Angle Processing | Optional equipment for angle processing, including additional shear and punching station |

| Stock Length Detection | Laser device for exact measurement prior to processing |

| Integration | Compatible with infeed and outfeed cross transfer tables for automated loading/unloading |

| Specification | Details |

|---|---|

| Processing Capabilities | Drilling, Scribing, Milling, Disc Sawing, Marking |

| Material Types | Angles, Flats, Channels, Square Tubes, Rectangular Tubes |

| Drilling Unit | Direct Drive spindle; 27 kW (37 HP) motor; 200 mm (7-7/8”) sub-axis stroke |

| Tool Changer | 8-position automatic tool changer |

| Mitering Disc Saw | Automatic positioning; miter cuts up to 60° in either direction |

| Marking Unit | Programmable for automatic part number generation |

| Second Drilling Unit | Optional; same specifications as the first |

| Angle Processing | Capable of full miter cuts on both ends for framing structures |

| Flat Processing | Handles up to 500 mm (20”) width; corner clipping capabilities |

| Loading System | Compatible with infeed and outfeed cross transfer tables for automated loading/unloading |

A: Industries like construction, shipbuilding, and energy gain efficiency and precision with these solutions.

A: Yes, FICEP’s machines are modular and customizable to meet unique production needs.

A:Absolutely, the systems are designed for seamless integration with minimal disruption.

A: Advanced automation minimizes waste by ensuring precise cutting and drilling.

A: FICEP offers comprehensive training, maintenance services, and technical support.