Ebbco Portable Filtration systems provide mobile, efficient solutions for tramp oil removal and sludge extraction, enhancing coolant quality and supporting cleaner, more productive machining operations.

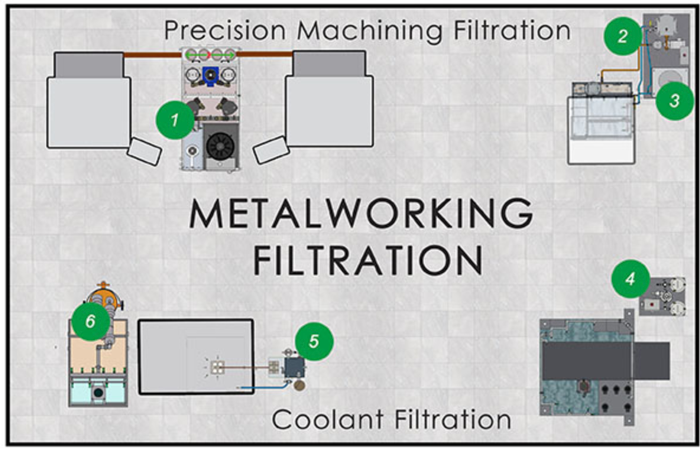

Ebbco’s Portable Filtration systems deliver efficient, mobile fluid filtration for CNC machining centers and lathes. These systems enhance coolant quality by removing tramp oils, sludge, and swarf, improving tool life and operational efficiency while ensuring cleaner machining environments.

Portable filtration solutions include the Oil Slick for tramp oil removal and the Sludge Wrangler for sludge and swarf extraction. Operating at 15 GPM, these compact systems are equipped with casters for mobility, ensuring seamless integration into diverse machining setups.

Portable filtration systems by Ebbco extend coolant life, reduce maintenance, and support cleaner operations. Their mobile design ensures flexibility, allowing quick deployment to various machines, which boosts overall productivity and operational efficiency.

Click the dropdowns below to view detailed specifications for the Portable Filtrations.

| Specification | Unit | Details |

|---|---|---|

| Application | CNC Machining Centers and Lathes | |

| Functionality | Removes Free & Mechanically Emulsified Tramp Oils | |

| Compatibility | Machine Tool Coolants | |

| Design | Compact, Portable | |

| Mobility | Equipped with Casters for Easy Transport |

| Specification | Unit | Details |

|---|---|---|

| Flow Rate | Gallons Per Minute | 15 GPM |

| Application | Sludge and Swarf Removal | |

| Compatibility | All Machines Using Coolant | |

| Design | Mobile with Casters | |

| Performance | Maintains Cleaner Coolants |

A: It operates at a flow rate of 15 gallons per minute.

A: It removes free and mechanically emulsified tramp oils from coolants.

A: Yes, both systems are equipped with casters for easy mobility.

A: They are compatible with CNC machining centers and lathes.

A: No, they are designed for easy setup and operation.