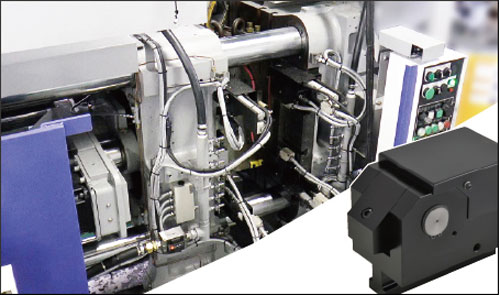

Kosmek’s Diecast Clamping Systems provide innovative solutions for precision and efficiency in die-casting operations. These systems ensure reliable clamping, fast changeovers, and enhanced productivity for various die-casting applications.

Kosmek’s Diecast Clamping Systems revolutionize die-casting with cutting-edge technology that ensures precision and durability. Designed to meet industry demands, these systems enable efficient mold clamping, minimizing downtime and maximizing output. Trusted by professionals worldwide, they support high performance in both large-scale and intricate die-casting projects.

Kosmek’s Diecast Clamping Systems feature advanced hydraulic clamping for secure and rapid mold positioning. Their modular design enhances compatibility with diverse die sizes, while quick-change capabilities minimize operational delays. Built for reliability, the systems are durable under high-pressure conditions, ensuring consistent performance.

Kosmek’s Diecast Clamping Systems reduce cycle times, improve productivity, and offer unmatched mold stability. Their innovative design lowers maintenance needs and enhances operational precision, making them a top choice for die-casting professionals seeking efficiency and dependability.

Click the dropdowns below to view detailed information for each model in the Diecast Clamping Systems Series.

| GKB Clamp T-Slot Manual Slide Clamp Model GKB | |

|---|---|

| Application | Designed for use under severe conditions where mold lubricant and/or molten metal may spatter. |

| Clamping Force | Up to 40 kN |

| Stroke Length | 10 mm |

| Operating Pressure | 3.5 MPa |

| Mounting | T-Slot |

| Features | Manual slide mechanism; suitable for high-temperature environments; resistant to mold lubricants and molten metal spatter. |

| GKC Clamp T-Slot Manual-Slide Clamp Model GKC | |

|---|---|

| Application | Longer stroke model of GKB Clamp for accommodating varying mold thicknesses. |

| Clamping Force | Up to 60 kN |

| Stroke Length | 20 mm |

| Operating Pressure | 3.5 MPa |

| Mounting | T-Slot |

| Features | Manual slide mechanism; extended stroke for diverse mold sizes; durable under severe conditions. |

| GKE Clamp T-Slot Automatic-Slide Clamp Model GKE | |

|---|---|

| Application | Automatic slide model of GKB Clamp for enhanced automation in mold clamping. |

| Clamping Force | Up to 40 kN |

| Stroke Length | 10 mm |

| Operating Pressure | 3.5 MPa |

| Mounting | T-Slot |

| Features | Automatic slide operation; suitable for integration into automated systems; resistant to harsh die-casting environments. |

| GKF Clamp T-Slot Automatic Slide Clamp Model GKF | |

|---|---|

| Application | Automatic slide model of GKC Clamp offering longer stroke for larger molds. |

| Clamping Force | Up to 60 kN |

| Stroke Length | 20 mm |

| Operating Pressure | 3.5 MPa |

| Mounting | T-Slot |

| Features | Automatic slide mechanism; extended stroke for accommodating larger molds; designed for severe operating conditions. |

| Hydraulic Unit Model CP□/CQ□/CT□/CU□ | |

|---|---|

| Application | Air-driven hydraulic unit suitable for automatic mold clamps in die casting machines. |

| Maximum Pressure | 7 MPa |

| Flow Rate | 10 L/min |

| Air Pressure | 0.5–0.7 MPa |

| Tank Capacity | 20 liters |

| Features | Compact design; efficient power conversion; suitable for various clamping applications. |

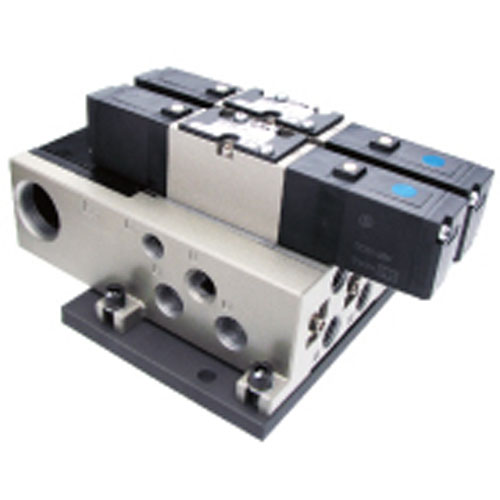

| Air Valve Unit Model MV | |

|---|---|

| Application | Air directional control valve actuated by electrical signal for controlling air cylinders in clamps. |

| Operating Pressure | 0.2–0.7 MPa |

| Flow Rate | Up to 600 L/min |

| Port Size | 1/4 inch |

| Control | Solenoid Actuated |

| Features | Compact design, high flow efficiency, and precise directional control for pneumatic systems. |

| MGC Clamp Model | |

|---|---|

| Application | Hydraulic slide clamp for securing molds in high-pressure die-casting applications. |

| Clamping Force | 80 kN |

| Stroke Length | 20 mm |

| Operating Pressure | 3.5 MPa |

| Mounting | Plate Mount |

| Features | Heavy-duty construction, high durability, and adjustable clamping force for a wide range of mold sizes. |

| GMA Clamp Model | |

|---|---|

| Application | Compact hydraulic clamp suitable for smaller molds in die-casting machines. |

| Clamping Force | 30 kN |

| Stroke Length | 15 mm |

| Operating Pressure | 3 MPa |

| Mounting | Side Mount |

| Features | Compact design, ideal for space-constrained setups, with high clamping precision. |

| GMS Clamp Model | |

|---|---|

| Application | Hydraulic swing clamp optimized for automated die-casting operations. |

| Clamping Force | 50 kN |

| Stroke Length | 20 mm |

| Operating Pressure | 3.5 MPa |

| Mounting | Plate Mount |

| Features | Swing arm design for efficient mold changes, durable under harsh conditions. |

| Hydraulic Power Pack Model HP | |

|---|---|

| Application | Provides hydraulic power for multiple clamping units in die-casting systems. |

| Maximum Pressure | 7 MPa |

| Tank Capacity | 50 liters |

| Flow Rate | 15 L/min |

| Dimensions | 800 mm x 600 mm x 1,000 mm |

| Features | Energy-efficient design, compact size, and high power output for demanding operations. |

A: These systems are ideal for automotive, aerospace, and industrial manufacturing sectors that rely on die-casting processes.

A: Kosmek’s systems are compatible with a wide range of mold sizes, thanks to their modular and adjustable design.

A: By enabling fast and secure clamping, they reduce setup times, allowing for quicker production cycles and higher output.

A: Yes, Kosmek’s Diecast Clamping Systems are designed for easy integration with standard die-casting machines.

A: The systems are low-maintenance, with robust components designed for high durability under demanding conditions.