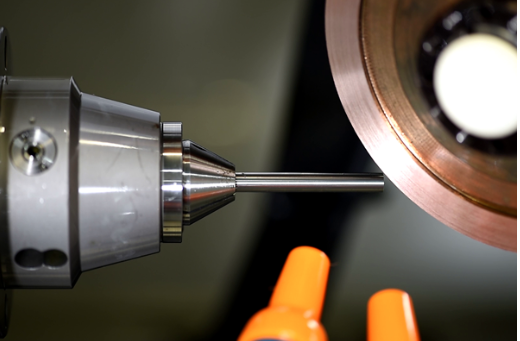

The EDG Range by ANCA offers advanced solutions for manufacturing and resharpening PCD, carbide (HM), and HSS tools. With integrated dual erosion and grinding spindles, these machines provide supreme flexibility for various tool types.

Electro Discharge Grinding (EDG) is a pivotal technology in modern tool manufacturing, enabling precise machining of hard materials like polycrystalline diamond (PCD). Its integration into the industry has revolutionized the production of high-performance cutting tools, meeting the increasing demand for durability and precision.

ANCA’s EDG machines feature the ANCA Motion SparX Erosion Generator, delivering superior cycle times and surface finishes. The Intelligent Adaptive Control (IAC) maintains optimal spark erosion gaps, ensuring efficiency in both simple and complex tool geometries. Additionally, the Adaptive Spark Control (ASC) optimizes the erosion process, enhancing tool quality and longevity.

Choosing ANCA’s EDG Range ensures high-quality tool production with reduced cycle times and improved surface finishes. The machines’ versatility accommodates various tool types, providing manufacturers with the flexibility to meet diverse customer needs. Enhanced tool longevity and precision lead to cost savings and increased productivity.

Click the dropdowns below to view detailed specifications for the EDG Range.

| EDG3 Specifications | |

|---|---|

| Machine Type | PCD, Carbide (HM), and HSS Tool Manufacture and Resharpening |

| Spindle Power | 9kW Double-Ended Erosion and Grinding Spindle |

| Tool Diameter Range | Manufacture: Up to 12mm; Resharpening: Up to 25.4mm |

| Tool Length (Max) | Flute length may vary depending on tooling |

| Wheel Pack Capacity | 2 Wheel Packs |

| Control System | ANCA Motion AMC5 CNC with Intel i7 Processor, 64GB SSD, 8GB DDR3 RAM |

| Connectivity | EtherCAT and USB |

| Automation | Optional ANCA FastLoad Automation Package |

| Dimensions (W x D x H) | Not specified |

| Weight | Not specified |

| EDG5 Specifications | |

|---|---|

| Machine Type | PCD, Carbide (HM), and HSS Tool Manufacture and Resharpening |

| Spindle Power | 12kW Double-Ended Erosion and Grinding Spindle |

| Tool Diameter Range | Manufacture: Up to 12mm; Resharpening: Up to 25.4mm |

| Tool Length (Max) | Flute length may vary depending on tooling |

| Wheel Pack Capacity | 2 Wheel Packs |

| Control System | ANCA Motion AMC5 CNC with Intel i7 Processor, 64GB SSD, 8GB DDR3 RAM |

| Connectivity | EtherCAT and USB |

| Automation | Optional ANCA FastLoad Automation Package |

| Dimensions (W x D x H) | Not specified |

| Weight | Not specified |

A: The EDG Range is designed for PCD, carbide (HM), and HSS tools, including drills, endmills, and profile tools.

A: IAC maintains the optimal spark erosion gap during machining, enhancing efficiency and precision in both simple and complex tool geometries.

A: The SparX Erosion Generator delivers superior cycle times and surface finishes, improving overall productivity and tool quality.

A: Yes, the integrated dual erosion and grinding spindles allow for hybrid machining, providing supreme flexibility.

A: The EDG Range is suitable for machining hard materials such as polycrystalline diamond (PCD), carbide (HM), and high-speed steel (HSS).