Piovan UnaDyn Granulators deliver efficient size reduction of plastic waste, ensuring clean, uniform granules for recycling. Advanced cutting technology minimizes energy use, heat, and dust.

Granulation is a vital process in the plastics industry, involving the size reduction of plastic waste and scrap into uniform granules for recycling and reuse. Piovan UnaDyn offers a comprehensive range of granulators designed to handle small, medium, and large capacities, ensuring efficient material processing and contributing to sustainable manufacturing practices.

Piovan UnaDyn’s granulators are engineered with advanced “Scissor” cutting technology, reducing energy consumption, heat, and dust generation. Models like the N45 are designed for heavy-duty applications, capable of processing up to 1,400 kg/h, and feature easy access for quick cleaning and maintenance. The G17 granulator offers maximum flexibility with various rotor configurations, ensuring adaptability to different processing needs.

Selecting Piovan UnaDyn’s granulators ensures efficient size reduction, leading to high-quality regrind material suitable for recycling. The advanced cutting action minimizes energy consumption and operational costs. Easy maintenance and accessibility features reduce downtime, enhancing overall productivity in plastic processing operations.

Click the dropdowns below to view detailed information for each model in the Granulation Series.

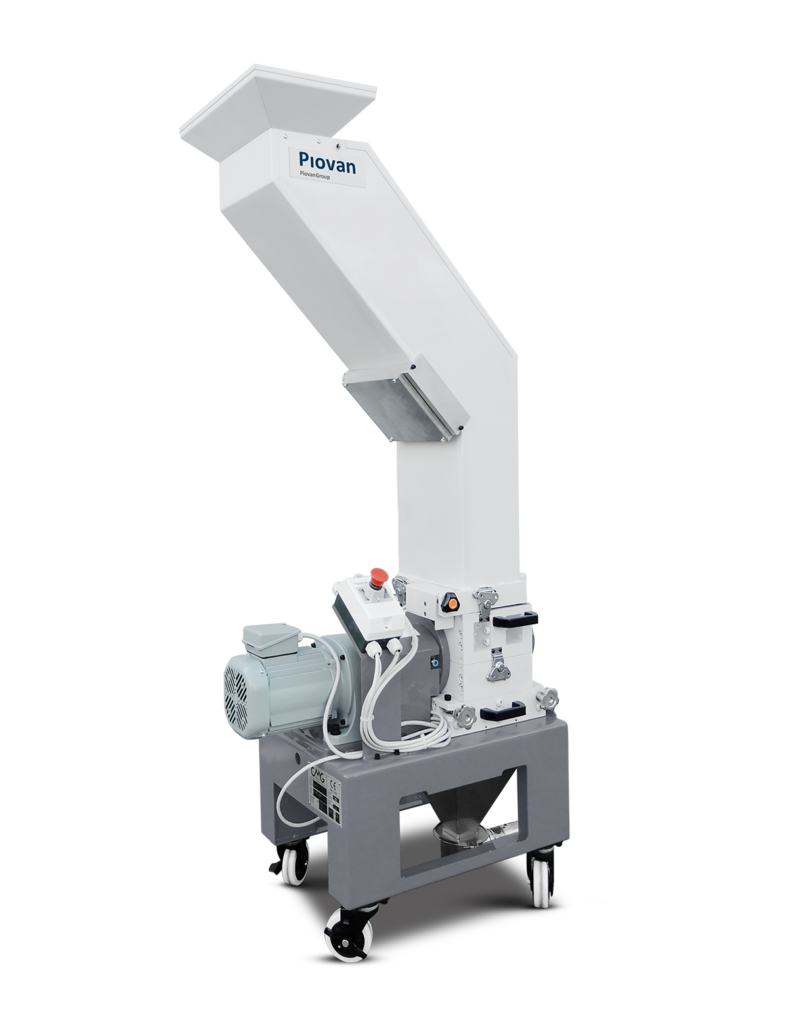

Designed for small injection molding machines, the G17 granulator offers up to 90 kg/h throughput. Its flexible rotor configuration ensures homogeneous regrind with minimal dust, while easy maintenance and low noise levels enhance operational efficiency.

Ideal for medium-sized applications, the G25 granulator provides up to 200 kg/h throughput. It features adjustable rotating knives for efficient cutting, compact dimensions for easy integration, and a range of discharge systems to meet diverse processing needs.

The B-S30 series is suitable for various applications, offering up to 340 kg/h throughput. Its advanced ‘Scissor’ cutting action reduces energy consumption, heat, and dust generation. Quick opening mechanisms facilitate easy cleaning and maintenance.

With a capacity of up to 700 kg/h, the G40 granulator is designed for versatility. It features high wear resistance with side plates, advanced ‘Scissor’ cutting action for energy efficiency, and a hinged hopper for easier cleaning and maintenance.

The N45 series is engineered for heavy-duty applications, handling up to 1,400 kg/h. It utilizes advanced ‘Scissor’ cutting technology to minimize energy use, heat, and dust. Hopper and screen cradles ensure easy access for quick cleaning and maintenance.

Designed for efficient size reduction of plastic and waste, these models og/h throughput. They feature advanced cutting action to reduce energy consumption, heat, and dust, along with wear-resistant rotors for durability and easy maintenance.

Specially designed for film extrusion processes, this granulator handles materials up to 680 mm wide. It offers different motor sizes for energy saving or higher cutting power, with quick opening for easy cleaning, ensuring efficient size reduction of edge trims and film.

The T and NT series are tailored for thermoforming processes, managing up to 1,800 kg/h. They efficiently reduce thermoforming sheets and scrap, including sheets with thermoformed lids, with models available for both in-line and off-line granulation. These granulators are designed to meet diverse processing needs, enhancing efficiency and productivity in plastic size reduction applications.

A: Piovan UnaDyn granulators are designed to process various materials, including plastics, rubber, and light metals, accommodating diverse industrial applications.

A: The “Scissor” cutting action reduces energy consumption, heat, and dust generation, resulting in efficient and clean granulation.

A: Yes, the G17 granulator is designed for small capacity IMMs, offering up to 90 kg/h throughput with flexible rotor configurations.

A: Piovan UnaDyn granulators feature easy access hoppers and screen cradles, ensuring quick cleaning and maintenance to minimize downtime.

A: Yes, the T and NT series are specifically designed for efficient reduction of thermoforming sheets, lids, and scrap, suitable for in-line or off-line granulation.