The NOVA sT Series (600-1300 tonnes) from Negri Bossi features advanced servo-hydraulic technology, compact X-Design toggle, and energy-efficient operation, ideal for high-performance injection molding.

The NOVA sT Series by Negri Bossi comprises servo-hydraulic injection molding machines with clamping forces ranging from 600 to 1300 tonnes. Designed for versatility and compactness, these machines cater to industries such as automotive, white goods, construction, and contract molding. Incorporating advanced servo-pump technology, the NOVA sT Series ensures energy-efficient operation, meeting the demands of modern injection molding applications.

The NOVA sT Series boasts an innovative X-Design toggle system, offering a compact footprint without compromising performance. Enhanced platen stroke and increased pressure on material improve molding capabilities. The inclusion of the Motus multi-touch controller provides intuitive gesture navigation, customizable interfaces, and efficient cycle sequencing. Additionally, the latest servo-pump technology ensures optimal energy efficiency during operation.

Selecting the NOVA sT Series means investing in machines that deliver versatility, productivity, and efficiency. The compact design saves valuable floor space, while the advanced servo-pump system reduces energy consumption, lowering operational costs. The user-friendly Motus controller enhances operational efficiency, making the NOVA sT Series a valuable asset for various injection molding applications.

Click the dropdowns below to view detailed specifications for the NOVA sT (600-1300 tonnes).

MAIN CHARACTERISTICS

The NOVA sT Series (600-1300 tonnes) from Negri Bossi combines advanced servo-hydraulic technology with innovative features to deliver superior precision, energy efficiency, and operational reliability. This makes it an ideal solution for large-scale injection molding applications.

X-DESIGN TOGGLE SYSTEM

The X-Design toggle system ensures compactness and stability, offering optimal force transmission and reduced mold wear. This innovative mechanism maximizes mold longevity while maintaining high-speed, dynamic performance.

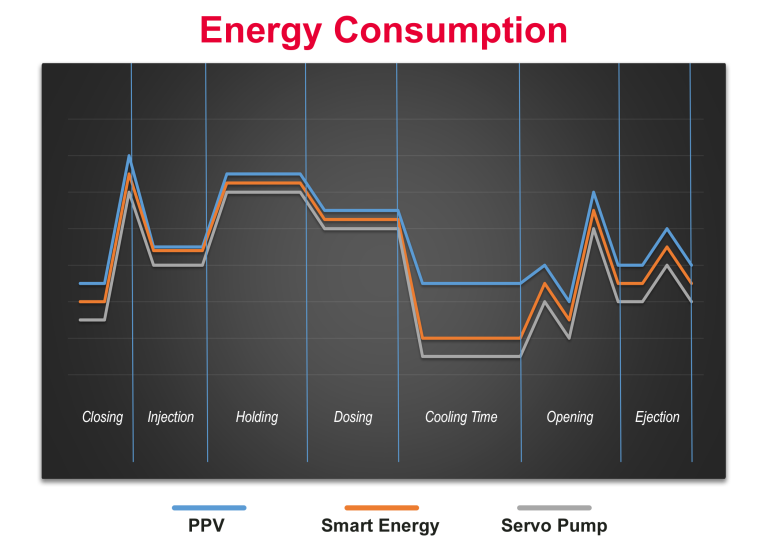

ADVANCED SERVO-PUMP TECHNOLOGY

Equipped with state-of-the-art servo-pump technology, the NOVA sT delivers exceptional energy savings, precise control, and quiet operation. This design ensures efficient and reliable performance for demanding manufacturing environments.

HIGH-DYNAMIC PLATEN MOVEMENT

The NOVA sT features an enhanced platen stroke with sensitive mold protection and automatic clamping adjustments, reducing the risk of mold damage while improving production efficiency.

PRISMATIC LINEAR GUIDES

Designed with prismatic linear guides, the machine guarantees accurate platen alignment, smooth operation, and a clean molding environment. These guides ensure precise mold positioning and high-quality output.

MOTUS CONTROLLER

The advanced Motus multi-touch controller offers intuitive gesture navigation, customizable interfaces, and real-time monitoring, providing users with a seamless and efficient operating experience.

REDUCED FOOTPRINT

With a compact design that saves up to 15% of floor space compared to similar models, the NOVA sT Series allows for optimized machine placement and increased factory throughput.

ENERGY EFFICIENCY

The energy-efficient design of the NOVA sT minimizes power consumption while maintaining superior performance, helping manufacturers reduce operational costs and meet sustainability goals.

ROBUST CLAMPING

The robust clamping system accommodates large molds and heavy-duty applications, ensuring stable and reliable production cycles.

These advanced features position the NOVA sT (600-1300 tonnes) as a top-tier choice for manufacturers seeking precision, efficiency, and flexibility in large-scale injection molding operations.

A: The NOVA sT Series is ideal for automotive, white goods, construction, and contract molding sectors.

A: The X-Design toggle system offers a compact footprint, saving floor space while maintaining high performance.

A: The Motus controller features intuitive gesture navigation, customizable interfaces, and efficient cycle sequencing, enhancing user experience and operational efficiency.

A: The series incorporates advanced servo-pump technology, designed specifically for injection molding, ensuring optimal energy consumption during operations.

A: The NOVA sT Series offers machines with clamping forces ranging from 600 to 1300 tonnes, accommodating various molding requirements.