The NPX7 Advance from Nissei combines efficient injection, hybrid energy-saving technology, advanced control, and precise molding, making it ideal for high-performance manufacturing needs.

The NPX7 Advance by Nissei is a compact hybrid injection molding machine designed for high-precision micro-molding applications. Combining the benefits of electric and hydraulic systems, it features Nissei’s innovative “X-Pump®” technology, delivering superior energy efficiency and performance. With a clamping force of 7.76 U.S. tons, the NPX7 Advance is ideal for producing micro parts weighing less than 1 gram, catering to industries such as medical devices, electronics, and automotive.

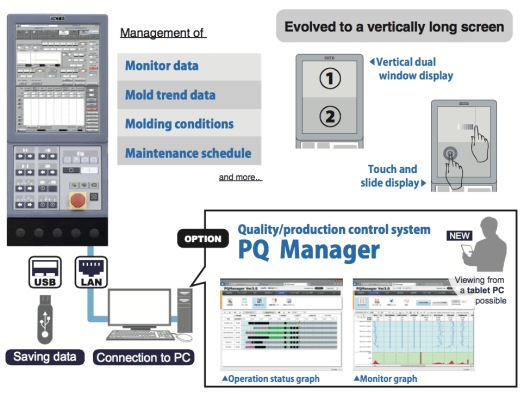

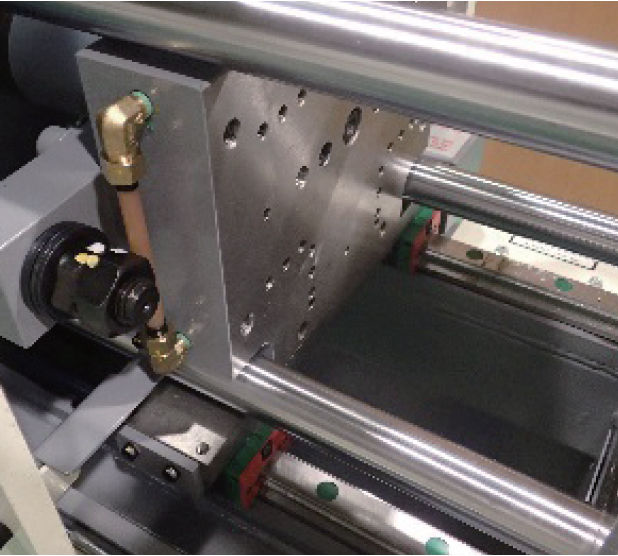

The NPX7 Advance boasts a groundbreaking 12mm inline screw, expanding its moldable range and enabling repeatable micro part production. Its high-rigidity direct-pressure clamping system ensures stable mold movements and uniform pressure distribution. Equipped with the TACT® Ⅳ Controller, it offers enhanced operability and comprehensive molding data management. The “X-Pump®” system achieves approximately 40% power savings compared to conventional hydraulic machines, providing outstanding injection performance with a high response time of 25 milliseconds and injection speeds up to 150mm/s.

Selecting the NPX7 Advance provides manufacturers with high-precision stable molding and exceptional energy efficiency. Its compact design is ideal for micro-molding applications, delivering consistent quality for small, intricate components. The machine’s advanced control system enhances productivity and ensures precise molding processes, making it a cost-effective solution for industries requiring meticulous manufacturing standards.

Click the dropdowns below to view detailed specifications for each model in the NPX7 Advance.

| Item | Unit | NPX7 Advance |

|---|---|---|

| Screw Diameter | inch (mm) | 0.47 (12) |

| Injection Capacity | inch³ (cm³) (oz) | 0.27 (4.5) (0.15) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 23,070 (159) (1622) |

| Clamping Force | USton (kN) (tf) | 7.76 (69) (7) |

| Clamping Stroke | inch (mm) | 6.70 (170) |

| Min. Mold Thickness | inch (mm) | 4.33 (110) |

| Max. Daylight Opening | inch (mm) | 11.02 (280) |

| Tie Bar Clearance (H×V) | inch (mm) | 6.70 x 6.12 (170 x 155) |

| Die Plate Dimensions (H×V) | inch (mm) | 9.05 x 8.86 (230 x 225) |

| Ejector Stroke | inch (mm) | 1.57 (40) |

A: Industries such as medical devices, electronics, and automotive benefit from the NPX7 Advance’s capability to produce high-precision micro parts.

A: The “X-Pump®” system combines electric and hydraulic advantages, achieving about 40% power savings compared to traditional hydraulic machines.

A: The NPX7 Advance features a high injection response time of 25 milliseconds, allowing for rapid and precise molding operations.

A: The TACT® Ⅳ Controller offers improved operability and molding data management, enhancing control over the injection molding process.

A: The NPX7 Advance supports a wide range of injection speeds, reaching up to 150mm/s, suitable for various molding requirements.