The DCX-Ⅲ Series from Nissei delivers multi-material molding, energy-efficient performance, precise control, and innovative features, making it perfect for advanced and complex injection molding needs.

The DCX-Ⅲ Series by Nissei comprises hybrid two-color/dissimilar material injection molding machines with clamping forces ranging from 121 to 813 tons (134 to 896 U.S. tons). These machines are engineered to enhance productivity and design flexibility in sectors such as automotive, industrial parts, and household goods. They feature Nissei’s proprietary 2-piston clamping mechanism, ensuring optimal clamping force distribution across molds.

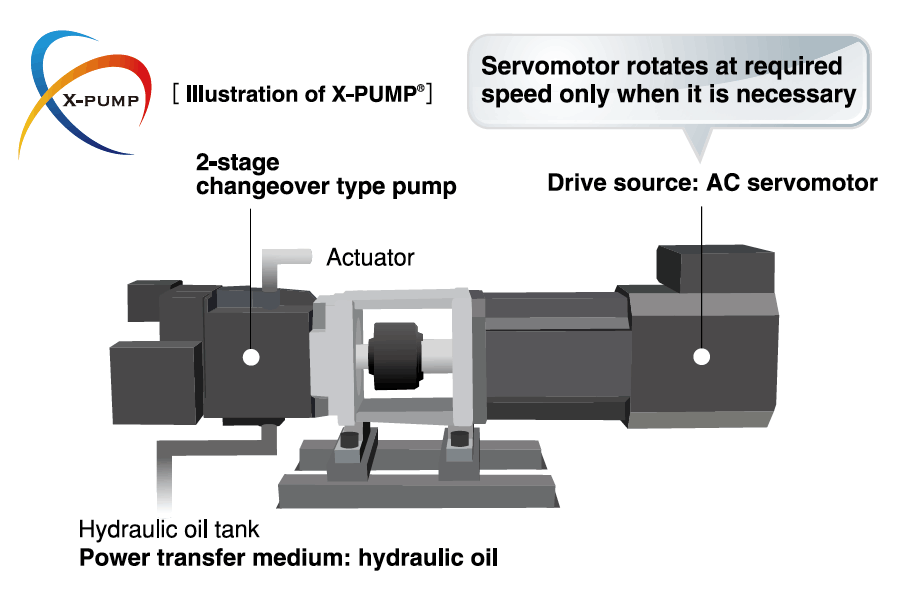

Key features of the DCX-Ⅲ Series include the innovative X-Pump® system, which combines hydraulic control with servomotor drive technologies for significant energy savings and improved injection repeatability. The TACT® Ⅳ controller offers high-speed, high-functioning control, enhancing operational efficiency. Additionally, a newly developed servo-driven rotation mechanism enables high-speed, shockless mold reversing, reducing reversing time by approximately half compared to conventional machines.

Choosing the DCX-Ⅲ Series provides substantial benefits, such as the ability to produce complex, multi-material products in a single process, thereby reducing assembly steps and cycle times. The machines’ energy-efficient operation lowers operational costs, while their advanced control systems ensure consistent, high-quality output. This makes them a valuable asset for manufacturers aiming to enhance efficiency and product quality.

Click the dropdowns below to view detailed specifications for each model in the DCX-III Series.

| Item | Unit | 9A (A: 9A & B: 9A) |

|---|---|---|

| Screw Diameter | inch (mm) | 1.02 (26), 1.10 (28), 1.26 (32), 1.42 (36) |

| Injection Capacity | inch³ (cm³) (oz) | 3.6 (59) (2.0), 4.2 (69) (2.3), 5.5 (90) (3.0), 7.0 (114) (3.8) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 38,450 (265) (2704), 35,410 (244) (2490), 27,140 (187) (1908), 21,330 (147) (1500) |

| Clamping Force | USton (kN) (tf) | 134 (1190) (121) |

| Clamping Stroke | inch (mm) | 17.7 (450) |

| Min. Mold Thickness | inch (mm) | 6.7 (170) |

| Max. Daylight Opening | inch (mm) | 24.4 (620) |

| Tie Bar Clearance (H×V) | inch (mm) | 26.0 x 9.8 (660 x 250) |

| Die Plate Dimensions (H×V) | inch (mm) | 31.5 x 18.9 (800 x 480) |

| Ejector Stroke | inch (mm) | 3.9 (100) |

| Item | Unit | 25A (A: 25A & B: 25A) |

|---|---|---|

| Screw Diameter | inch (mm) | 1.42 (36), 1.57 (40), 1.77 (45), 1.97 (50) |

| Injection Capacity | inch³ (cm³) (oz) | 9.95 (163) (5.5), 12.3 (201) (6.7), 15.5 (254) (8.5), 19.2 (314) (10.5) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 37,000 (255) (2602), 31,780 (219) (2235), 25,100 (173) (1765), 20,320 (140) (1429) |

| Clamping Force | USton (kN) (tf) | 224 (1990) (203) |

| Clamping Stroke | inch (mm) | 20.5 (520) |

| Min. Mold Thickness | inch (mm) | 9.8 (250) |

| Max. Daylight Opening | inch (mm) | 30.3 (770) |

| Tie Bar Clearance (H×V) | inch (mm) | 36.4 x 12.0 (925 x 305) |

| Die Plate Dimensions (H×V) | inch (mm) | 42.1 x 22.4 (1070 x 570) |

| Ejector Stroke | inch (mm) | 3.9 (100) |

| Item | Unit | 36A (A: 36A & B: 36A) |

|---|---|---|

| Screw Diameter | inch (mm) | 1.77 (45), 1.97 (50), 2.20 (56) |

| Injection Capacity | inch³ (cm³) (oz) | 17.5 (286) (9.6), 21.5 (353) (11.8), 27.0 (443) (14.8) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 30,040 (207) (2112), 24,380 (168) (1714), 19,450 (134) (1367) |

| Clamping Force | USton (kN) (tf) | 446 (3970) (405) |

| Clamping Stroke | inch (mm) | 29.5 (750) |

| Min. Mold Thickness | inch (mm) | 11.8 (300) |

| Max. Daylight Opening | inch (mm) | 41.3 (1050) |

| Tie Bar Clearance (H×V) | inch (mm) | 44.1 x 16.5 (1120 x 420) |

| Die Plate Dimensions (H×V) | inch (mm) | 53.5 x 31.9 (1360 x 810) |

| Ejector Stroke | inch (mm) | 4.7 (120) |

| Item | Unit | 50A (A: 50A & B: 50A) |

|---|---|---|

| Screw Diameter | inch (mm) | 1.97 (50), 2.20 (56), 2.48 (63) |

| Injection Capacity | inch³ (cm³) (oz) | 24.5 (402) (13.5), 30.8 (505) (16.9), 39.0 (639) (21.4) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 28,730 (198) (2020), 22,930 (158) (1612), 18,140 (125) (1276) |

| Clamping Force | USton (kN) (tf) | 661 (5880) (600) |

| Clamping Stroke | inch (mm) | 33.5 (850) |

| Min. Mold Thickness | inch (mm) | 17.7 (450) |

| Max. Daylight Opening | inch (mm) | 51.2 (1300) |

| Tie Bar Clearance (H×V) | inch (mm) | 59.6 x 22.2 (1515 x 565) |

| Die Plate Dimensions (H×V) | inch (mm) | 72.0 x 40.6 (1830 x 1030) |

| Ejector Stroke | inch (mm) | 7.1 (180) |

| Item | Unit | 71A (A: 71A & B: 71A) |

|---|---|---|

| Screw Diameter | inch (mm) | 2.20 (56), 2.48 (63), 2.80 (71) |

| Injection Capacity | inch³ (cm³) (oz) | 33.8 (554) (18.6), 42.8 (701) (23.5), 54.4 (891) (29.9) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 28,440 (196) (2000), 22,490 (155) (1582), 17,700 (122) (1245) |

| Clamping Force | USton (kN) (tf) | 896 (7965) (813) |

| Clamping Stroke | inch (mm) | 40.4 (1025) |

| Min. Mold Thickness | inch (mm) | 17.7 (450) |

| Max. Daylight Opening | inch (mm) | 58.1 (1475) |

| Tie Bar Clearance (H×V) | inch (mm) | 73.6 x 28.0 (1870 x 710) |

| Die Plate Dimensions (H×V) | inch (mm) | 85.4 x 47.2 (2170 x 1200) |

| Ejector Stroke | inch (mm) | 7.9 (200) |

A: The series offers clamping forces ranging from 121 to 813 tons (134 to 896 U.S. tons), accommodating various molding requirements.

A: The X-Pump® system integrates hydraulic control with servomotor drive technologies, resulting in significant energy savings and enhanced injection repeatability.

A: Nissei’s original 2-piston clamping mechanism ensures ideal clamping force distribution to both sides of the mold, enhancing mold longevity and product quality.

A: Yes, the series is designed for two-color and dissimilar material molding, enabling the production of complex, multi-material products in a single process cycle.

A: Industries such as automotive, industrial parts manufacturing, and household goods production benefit from the series’ capabilities in producing high-designability and functional products efficiently.