The TNX-RⅢ Series from Nissei ensures precise overmolding, fast cycle times, superior energy savings, and reliable clamping, ideal for efficient insert molding applications.

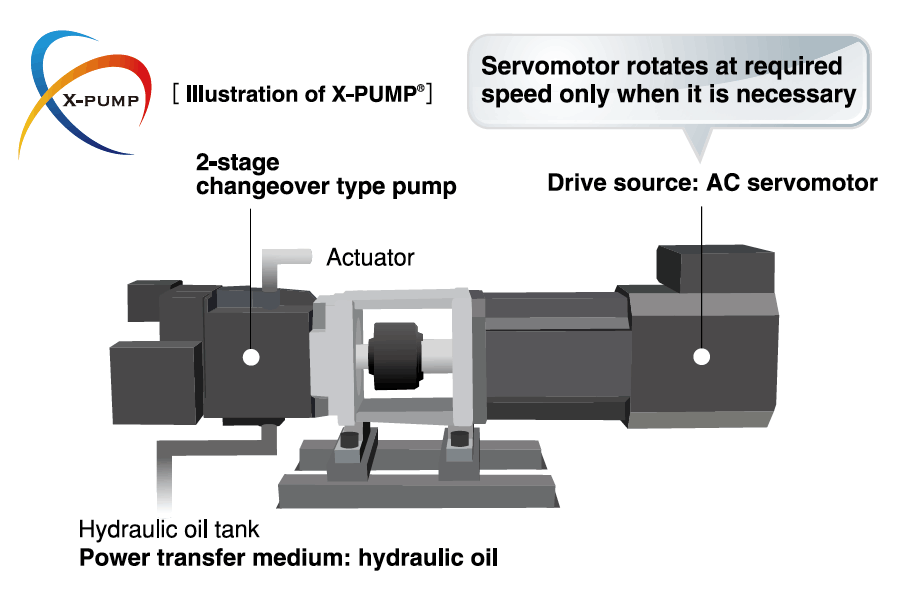

The TNX-RⅢ Series by Nissei is a vertical hybrid injection molding machine featuring the innovative X-Pump® system, which combines hydraulic control with servomotor drive technologies. This design ensures exceptional energy efficiency and outstanding injection performance. Equipped with a turntable, the TNX-RⅢ Series is ideal for insert molding applications, offering enhanced productivity and precision.

Key features of the TNX-RⅢ Series include a mold-friendly direct pressure clamping mechanism that provides stable clamping force, ensuring long-lasting machine precision. The 3-tie bar wide turntable accommodates larger molds and improves workability for mold installation. Additionally, the TACT® Ⅳ controller offers a user-friendly interface with a 15-inch color LCD touch panel and supports multiple languages, enhancing operability and production management.

Choosing the TNX-RⅢ Series provides significant energy savings due to the X-Pump® system, which operates the servomotor only when necessary, reducing running costs. The machine’s compact design allows for efficient use of space and facilitates automation integration. Its simple mechanism ensures easy maintenance, contributing to long-term operational stability and reliability.

Click the dropdowns below to view detailed specifications for each model in the TNX-RIII Series.

| Item | Unit | 5V (Turntable) | 9V (Turntable) |

|---|---|---|---|

| Screw Diameter | inch (mm) | 0.87 (22), 1.02 (26), 1.18 (30) | 1.10 (28), 1.26 (32), 1.42 (36) |

| Injection Capacity | inch³ (cm³) (oz) | 2.1 (35) (1.2), 3.0 (49) (1.6), 4.0 (65) (2.2) | 4.2 (69) (2.3), 5.5 (90) (3.0), 7.0 (114) (3.8) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 37,120 (256) (2610), 26,590 (183) (1870), 19,980 (138) (1405) | 35,410 (244) (2490), 27,020 (187) (1900), 21,330 (147) (1500) |

| Clamping Force | USton (kN) (tf) | 59 (523) (53) | Same as 5V |

| Clamping Stroke | inch (mm) | 9.8 (250) | Same as 5V |

| Min. Mold Thickness | inch (mm) | 6.7 (170) | Same as 5V |

| Max. Daylight Opening | inch (mm) | 16.5 (420) | Same as 5V |

| Die Plate Dimensions (H×V) | inch (mm) | 21.7 x 15.7 (550 x 400) | Same as 5V |

| Ejector Stroke | inch (mm) | 2.0 (50) | Same as 5V |

| Item | Unit | 9V (Turntable) | 12V (Turntable) |

|---|---|---|---|

| Screw Diameter | inch (mm) | 1.10 (28), 1.26 (32), 1.42 (36) | 1.26 (32), 1.42 (36), 1.57 (40) |

| Injection Capacity | inch³ (cm³) (oz) | 4.2 (69) (2.3), 5.5 (90) (3.0), 7.0 (114) (3.8) | 6.1 (100) (3.4), 7.7 (127) (4.3), 9.6 (157) (5.3) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 35,410 (244) (2490), 27,020 (187) (1900), 21,330 (147) (1500) | 32,850 (226) (2310), 25,950 (179) (1825), 21,050 (145) (1480) |

| Clamping Force | USton (kN) (tf) | 85 (754) (77) | Same as 9V |

| Clamping Stroke | inch (mm) | 9.8 (250) | Same as 9V |

| Min. Mold Thickness | inch (mm) | 7.9 (200) | Same as 9V |

| Max. Daylight Opening | inch (mm) | 17.7 (450) | Same as 9V |

| Die Plate Dimensions (H×V) | inch (mm) | 23.6 x 18.1 (600 x 460) | Same as 9V |

| Ejector Stroke | inch (mm) | 2.0 (50) | Same as 9V |

| Item | Unit | 12V (Turntable) | 18V (Turntable) |

|---|---|---|---|

| Screw Diameter | inch (mm) | 1.26 (32), 1.42 (36), 1.57 (40) | 1.42 (36), 1.57 (40), 1.77 (45) |

| Injection Capacity | inch³ (cm³) (oz) | 6.1 (100) (3.4), 7.7 (127) (4.3), 9.6 (157) (5.3) | 9.0 (147) (4.9), 11.1 (182) (6.1), 14.1 (231) (7.7) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 32,850 (226) (2310), 25,950 (179) (1825), 21,050 (145) (1480) | 33,280 (222) (2270), 26,170 (180) (1840), 20,610 (142) (1450) |

| Clamping Force | USton (kN) (tf) | 115 (1026) (105) | Same as 12V |

| Clamping Stroke | inch (mm) | 9.8 (250) | Same as 12V |

| Min. Mold Thickness | inch (mm) | 11.8 (300) | Same as 12V |

| Max. Daylight Opening | inch (mm) | 21.7 (550) | Same as 12V |

| Die Plate Dimensions (H×V) | inch (mm) | 27.6 x 20.1 (700 x 510) | Same as 12V |

| Ejector Stroke | inch (mm) | 2.0 (50) | Same as 12V |

| Item | Unit | 18V (Turntable) | 25V (Turntable) |

|---|---|---|---|

| Screw Diameter | inch (mm) | 1.42 (36), 1.57 (40), 1.77 (45) | 1.57 (40), 1.77 (45), 1.97 (50) |

| Injection Capacity | inch³ (cm³) (oz) | 9.0 (147) (4.9), 11.1 (182) (6.1), 14.1 (231) (7.7) | 12.3 (201) (6.7), 15.5 (254) (8.5), 19.2 (314) (10.5) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 33,280 (222) (2270), 26,170 (180) (1840), 20,610 (142) (1450) | 32,280 (222) (2270), 25,390 (175) (1790), 21,610 (142) (1450) |

| Clamping Force | USton (kN) (tf) | 165 (1469) (150) | Same as 18V |

| Clamping Stroke | inch (mm) | 9.8 (250) | Same as 18V |

| Min. Mold Thickness | inch (mm) | 13.8 (350) | Same as 18V |

| Max. Daylight Opening | inch (mm) | 23.6 (600) | Same as 18V |

| Die Plate Dimensions (H×V) | inch (mm) | 30.7 x 23.6 (780 x 600) | Same as 18V |

| Ejector Stroke | inch (mm) | 3.1 (80) | Same as 18V |

A: The series offers clamping forces ranging from 53 to 150 tons (59 to 165 U.S. tons), suitable for various molding requirements.

A: The X-Pump® system combines hydraulic control with servomotor drive technologies, operating the servomotor only when needed, which significantly reduces energy consumption.

A: This mechanism provides stable clamping force, evenly distributing pressure across the mold, which enhances mold longevity and product quality.

A: Yes, the turntable design and wide work area make it ideal for automated insert molding applications, facilitating robot integration.

A: The TACT® Ⅳ controller includes a 15-inch color LCD touch panel, multi-language support, and enhanced production management capabilities, improving user operability.