The FVX-III Series from Nissei offers rapid mold changes, adaptable clamping, exceptional efficiency, improved safety, and cost-effective solutions, perfect for enhancing injection molding performance.

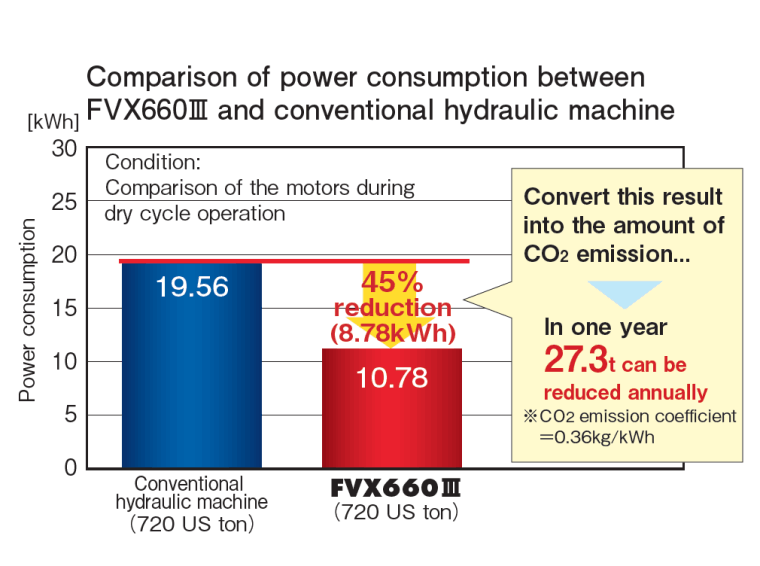

The FVX-Ⅲ Series by Nissei comprises large hybrid injection molding machines with clamping forces ranging from 561 to 1,306 tons. These machines integrate Nissei’s innovative “X-Pump®” system, combining hydraulic and servomotor technologies to achieve significant energy savings. Designed for high efficiency and reliability, the FVX-Ⅲ Series caters to diverse manufacturing needs, offering enhanced performance and operational flexibility.

Key features of the FVX-Ⅲ Series include a high-rigidity direct-pressure clamping system that ensures stable mold clamping and superior injection performance. The “X-Pump®” system provides quick response times and maintains long-sustained, high-pressure injection holding pressure. Additionally, the TACT® Ⅳ controller offers a user-friendly interface with a 15-inch vertical LCD, facilitating easy operation and improved production management.

Opting for the FVX-Ⅲ Series delivers substantial energy savings, reducing operational costs while maintaining high performance. The machines’ low maintenance requirements and low-noise operation contribute to a more efficient and comfortable working environment. Their versatile design accommodates various molding applications, making them a valuable asset for manufacturers seeking to enhance productivity and product quality.

Click the dropdowns below to view detailed specifications for each model in the PNX-III Series.

| Item | Unit | 210L | 310L |

|---|---|---|---|

| Screw Diameter | inch (mm) | 3.1 (80), 3.5 (90) | 3.5 (90), 3.9 (100) |

| Injection Capacity | inch³ (cm³) (oz) | 219 (2110) (70.7), 163 (2670) (89.5) | 194 (3180) (107), 240 (3930) (132) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 27,020 (186) (1900), 21,330 (147) (1500) | 26,560 (183) (1870), 21,480 (148) (1510) |

| Clamping Force | USton (kN) (tf) | 618 (5500) (561) | Same as 210L |

| Clamping Stroke | inch (mm) | 35.4 (900) | Same as 210L |

| Mold Thickness (min.-max.) | inch (mm) | 15.7 | Same as 210L |

| Max. Daylight Opening | inch (mm) | 71.3 (1810) | Same as 210L |

| Tie Bar Clearance (H×V) | inch (mm) | 38.2 x 38.2 (970 x 970) | Same as 210L |

| Die Plate Dimensions (H×V) | inch (mm) | 53.5 x 53.5 (1360 x 1360) | Same as 210L |

| Ejector Stroke | inch (mm) | 7.1 (180) | Same as 210L |

| Item | Unit | 310L | 400L |

|---|---|---|---|

| Screw Diameter | inch (mm) | 3.5 (90), 3.9 (100) | 3.9 (100), 4.4 (112) |

| Injection Capacity | inch³ (cm³) (oz) | 194 (3180) (107), 240 (3930) (132) | 244 (4000) (134), 306 (5020) (168) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 26,560 (183) (1870), 21,480 (148) (1510) | 24,230 (167) (1710), 19,340 (133) (1360) |

| Clamping Force | USton (kN) (tf) | 720 (6390) (653) | Same as 310L |

| Clamping Stroke | inch (mm) | 37.4 (950) | Same as 310L |

| Mold Thickness (min.-max.) | inch (mm) | 17.7 | Same as 310L |

| Max. Daylight Opening | inch (mm) | 75.2 (1910) | Same as 310L |

| Tie Bar Clearance (H×V) | inch (mm) | 43.3 x 43.3 (1100 x 1100) | Same as 310L |

| Die Plate Dimensions (H×V) | inch (mm) | 60.6 x 60.6 (1540 x 1540) | Same as 310L |

| Ejector Stroke | inch (mm) | 7.9 (200) | Same as 310L |

| Item | Unit | 400L | 600L |

|---|---|---|---|

| Screw Diameter | inch (mm) | 3.9 (100), 4.4 (112) | 4.4 (112), 4.9 (125) |

| Injection Capacity | inch³ (cm³) (oz) | 244 (4000) (134), 306 (5020) (168) | 367 (6010) (201), 456 (7480) (251) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 24,320 (167) (1710), 19,340 (133) (1360) | 24,890 (171) (1750), 20,050 (138) (1410) |

| Clamping Force | USton (kN) (tf) | 946 (8410) (858) | Same as 400L |

| Clamping Stroke | inch (mm) | 46.3 (1175) | Same as 400L |

| Mold Thickness (min.-max.) | inch (mm) | 19.7 | Same as 400L |

| Max. Daylight Opening | inch (mm) | 89.0 (2260) | Same as 400L |

| Tie Bar Clearance (H×V) | inch (mm) | 52.4 x 52.4 (1330 x 1330) | Same as 400L |

| Die Plate Dimensions (H×V) | inch (mm) | 70.9 x 70.9 (1800 x 1800) | Same as 400L |

| Ejector Stroke | inch (mm) | 7.9 (200) | Same as 400L |

| Item | Unit | 600L |

|---|---|---|

| Screw Diameter | inch (mm) | 4.4 (112), 4.9 (125) |

| Injection Capacity | inch³ (cm³) (oz) | 367 (6010) (201), 456 (7480) (251) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 24,890 (171) (1750), 20,050 (138) (1410) |

| Clamping Force | USton (kN) (tf) | 1,207 (10,730) (1,095) |

| Clamping Stroke | inch (mm) | 49.2 (1250) |

| Mold Thickness (min.-max.) | inch (mm) | 23.6 |

| Max. Daylight Opening | inch (mm) | 94.9 (2410) |

| Tie Bar Clearance (H×V) | inch (mm) | 55.1 x 55.1 (1400 x 1400) |

| Die Plate Dimensions (H×V) | inch (mm) | 78.0 x 78.0 (1980 x 1980) |

| Ejector Stroke | inch (mm) | 7.9 (200) |

| Item | Unit | 700L | 1100L* |

|---|---|---|---|

| Screw Diameter | inch (mm) | 4.7 (112), 5.3 (135) | 4.9 (125), 5.5 (140), 5.9 (150) |

| Injection Capacity | inch³ (cm³) (oz) | 428 (7010) (235), 541 (8870) (297) | 535 (8774) (294), 672 (11006) (369), 771 (12635) (423) |

| Max. Injection Pressure | psi (MPa) (kgf/cm²) | 24,460 (168) (1720), 19,340 (133) (1360) | 29,150 (201) (2050), 23,180 (160) (1630), 20,340 (140) (1430) |

| Clamping Force | USton (kN) (tf) | 1,439 (12,800) (1,306) | Same as 700L |

| Clamping Stroke | inch (mm) | 51.2 (1300) | Same as 700L |

| Mold Thickness (min.-max.) | inch (mm) | 27.6 | Same as 700L |

| Max. Daylight Opening | inch (mm) | 100.8 (2560) | Same as 700L |

| Tie Bar Clearance (H×V) | inch (mm) | 57.1 x 57.1 (1450 x 1450) | Same as 700L |

| Die Plate Dimensions (H×V) | inch (mm) | 79.5 x 79.5 (2020 x 2020) | Same as 700L |

| Ejector Stroke | inch (mm) | 11.0 (280) | Same as 700L |

A: The series offers clamping forces ranging from 561 to 1,306 tons, suitable for various manufacturing requirements.

A:The “X-Pump®” system combines hydraulic and servomotor technologies, operating the servomotor only when necessary, leading to significant energy savings.

A: The TACT® Ⅳ controller features a 15-inch vertical LCD and a user-friendly interface, enhancing operability and production management.

A: Yes, with high clamping forces and advanced injection capabilities, they are ideal for large-scale manufacturing applications.

A: The FVX-Ⅲ Series is designed for easy maintenance, featuring durable components and systems that minimize downtime.