The HLGW Series by HSG Laser delivers high-speed, high-precision laser welding with powerful automation and intelligent monitoring, ideal for advanced industrial metal joining needs.

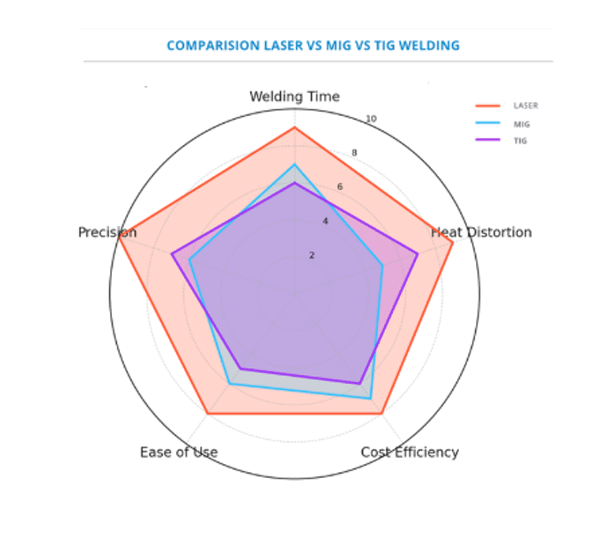

Laser welding machines are transforming precision manufacturing with clean, strong, and efficient welds. The HLGW Series stands out in industrial settings for its seamless integration, reliable performance, and intelligent functions, delivering exceptional results in automated production lines.

The HLGW Series features a handheld or robotic welding head, advanced fiber laser source, precision auto wire feeder, and real-time welding monitoring. With support for varied metals, automatic seam tracking, and customizable welding patterns, this system enhances both versatility and consistency in demanding environments.

Choose the HLGW Series to boost productivity, reduce labor costs, and ensure clean, high-quality welds. Its intuitive operation and advanced automation deliver consistent performance for modern fabrication.

Click the dropdowns below to view detailed specifications for the HLGW Series.

Specification | Metric | Imperial |

Max. Laser Source Power | 2kw | 2000KW |

Robot Arm | FANUC CRX10iAL | |

Number of Control Axes | 6-Axis | |

Operating Range (X, Y) | 1417.3mm, 2834.6mm (to the flange tip) (J4=+90°) | 55.8in, 111.6in (to the flange tip) (J4=+90°) |

Repeatability | ±0.0399 mm | ±0.00157 in |

Core Attribute | Automated, Collaborative Laser Welding: Intuitive robot programming and seamless switching between manual and robotic modes High-Precision, Repeatable Welds: Boosts productivity while reducing operator fatigue and labor costs Built-in Safety Features and Flexible Configuration | |

A: The HLGW Series can weld stainless steel, carbon steel, aluminum, galvanized sheet, and other metals with high precision and consistency.

A: Yes, it includes a precision automatic wire feeder for improved weld strength, quality, and consistency, especially for gap bridging applications.

A: Absolutely. It supports integration with robotic arms, making it ideal for automated production lines and high-volume operations.

A: The system includes intelligent real-time monitoring and optional visual seam tracking to ensure precision and minimize defects.

A: Automotive, aerospace, electronics, and sheet metal industries benefit from its speed, automation, and reliability in complex welding tasks.