The HC Series Press Brakes from HSG Laser deliver high-precision metal bending with smart automation, CNC control, and energy efficiency for streamlined and reliable production performance.

The HC Series Press Brakes by HSG Laser are advanced metal forming machines tailored for high-precision bending in sheet metal fabrication. With smart CNC control, reliable hydraulic systems, and automation readiness, the HC Series supports efficient workflows across industries like automotive, aerospace, and heavy machinery manufacturing.

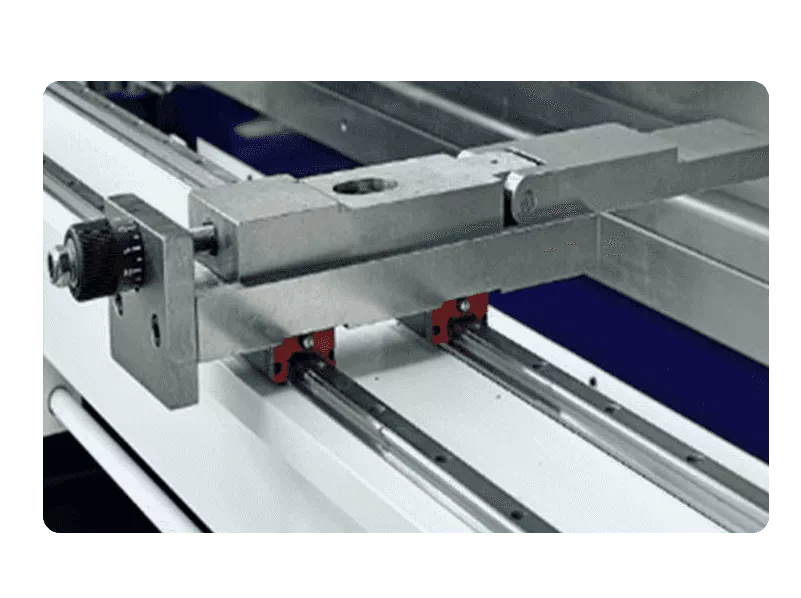

HC Series Press Brakes feature an intelligent CNC system, electro-hydraulic servo synchronization, and a high-rigidity frame for consistent accuracy. The fast backgauge and auto crowning system ensure tight tolerances. Optional robotic integration and smart tools enable flexible, high-efficiency metal forming operations for diverse applications.

HSG’s HC Series offers unmatched precision, energy savings, and automated performance for modern fabrication. Users gain reduced setup times, improved throughput, and consistent part quality.

Click the dropdowns below to view detailed specifications for the HC Series.

Specification | Metric | Imperial |

Bending Force | 1100KN (HC-1103) 2500KN (HC-2504) 4000KN (HC-4006) 800KN (HC-8025) | 124 ton (HC-1103) 281 ton (HC-2504) 450 ton (HC-4006) 90 ton (HC-8025) |

Controlled Axis | 4 + 1; can customize to 6 + 1 or 8 + 1 | |

Throat Depth | 400mm | |

Rapid Descent Speed | 200mm/sec (HC-1103) 150mm/sec (HC-2504) 90mm/sec (HC-4006) 180mm/s (HC-8025) | 7.87in/sec (HC-1103) 5.91in/sec (HC-2504) 3.54in/sec (HC-4006) 7.09in/sec (HC-8025) |

Return Speed | 150mm/sec (HC-1103) 120mm/sec (HC-2504) 70mm/sec (HC-4006) 140mm/sec (HC-8025) | 5.91in/sec (HC-1103) 4.72in/sec (HC-2504) 2.76in/sec (HC-4006) 5.51in/sec (HC-8025) |

Fuel Tank Capacity | 200L (HC-1103) 400L (HC-2504) 600L (HC-4006) 250L (HC-8025) | 52.83gal (HC-1103) 105.67gal (HC-2504) 158.4gal (HC-4006) 66.04gal (HC-8025) |

Whole Equipment Weight | 8000kg (HC-1103) 16000kg (HC-2504) 28000kg (HC-4006) 7000kg (HC-8025) | 17637lbs (HC-1103) 35274lbs (HC-2504) 61729lbs (HC-4006) 15432lbs (HC-8025) |

Core Attribute | Electro-Hydraulic Precision: Powered by an energy-efficient servo system for accurate and repeatable bending operations Smart CNC Control: Equipped with high-speed back gauges and automatic crowning to ensure consistent results across various materials Built for the Long Haul: Rugged construction paired with intelligent automation makes it a perfect fit for advanced fabrication environments Seamless Line Integration: Designed to smoothly integrate into smart production lines for increased productivity and workflow efficiency | |

A: The HC Series can bend a wide range of metals, including carbon steel, stainless steel, aluminum, and copper alloys.

A: Yes, the HC Series is automation-ready and can integrate with robotic arms and smart loading systems to optimize workflows.

A: It uses advanced CNC systems that support multi-axis control, precise programming, and real-time monitoring for complex bending tasks.

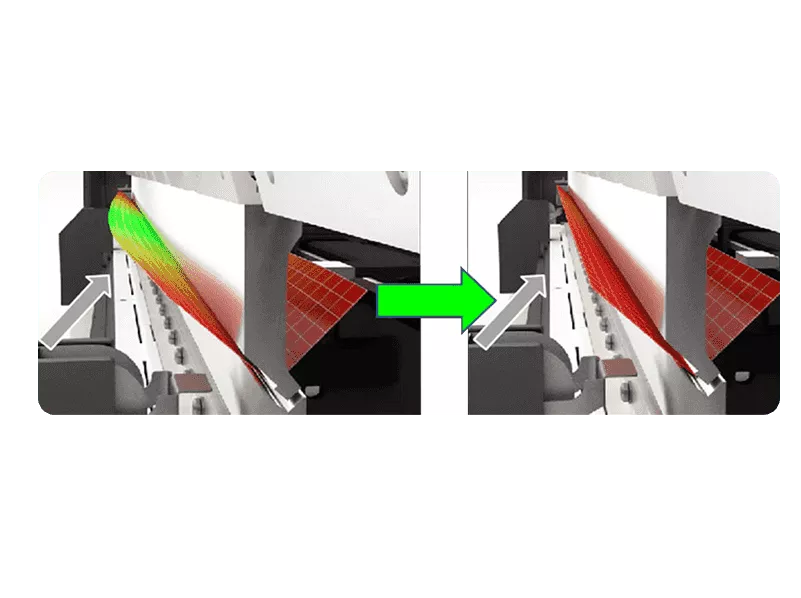

A: The HC Series achieves high bending accuracy through electro-hydraulic synchronization and dynamic crowning compensation systems.

A: Absolutely. Its fast setup, tool-changing capabilities, and repeatability make it ideal for both small batch jobs and large-scale production.