TPSD Series from HSG Laser offers advanced compound tube laser cutting with integrated drilling and tapping, engineered for high precision and productivity in metal fabrication.

The TPSD Series compound tube laser cutting machine from HSG Laser introduces a powerful all-in-one solution for cutting, drilling, and tapping tubes. Designed for industries requiring high-precision metal processing, it streamlines complex fabrication tasks and enhances workflow efficiency. With automatic loading and intelligent control systems, the TPSD stands out in modern manufacturing environments.

TPSD integrates fiber laser cutting with automated drilling and tapping to support square, round, and special-shaped tubes. It features four-chuck positioning, 360° rotation, and full-stroke clamping. With a pipe range up to 350mm, dual power drilling spindles, and automatic material loading, TPSD ensures precision, speed, and versatility in one machine.

Choosing the TPSD Series means faster production, fewer setups, and maximum versatility. It reduces labor costs by integrating multiple functions into one system and supports complex tube structures with high accuracy.

Click the dropdowns below to view detailed specifications for the TPSD.

Specification | Metric | Imperial |

Laser Power | 3kW – 6kW | 3000W – 6000W |

Tube Processing Range | Round tube: 12mm – 254mm Square tube: 20mm x 20mm – 200mm x 200mm Side Length≤200mm | Round tube: 0.47in – 10in Square tube: 0.79in x 0.79in – 7.87in x 7.87in Side Length≤7.87in |

Range of Incoming Materials for Tube | 1000mm – 6500mm | 39.37in – 255.91in |

Positioning Precision of X/Y Axis | ±0.03mm/m | ±0.00035 in/ft |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.00118 in |

Speed of Chuck | 120 RMP | |

Max Linkage Speed | 120m/min | 393.7 ft/min |

Max Linkage Acceleration | 1.2 G | |

Max Single Tube Weight | About 200kg | About 441lb |

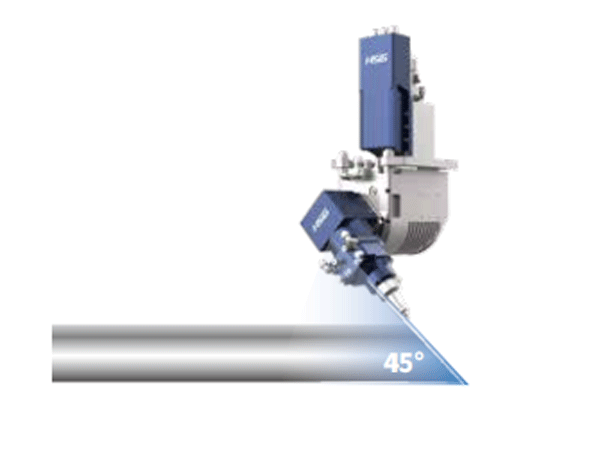

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

Core Attributes | All-in-One Processing: Combines cutting, drilling, and tapping in a single, streamlined machine High-Speed Precision: Capable of producing complex patterns with accuracy and efficiency Optional Automated Material Handling: Supports advanced loading and unloading systems for uninterrupted productivity | |

A: The TPSD can cut round, square, rectangular, and special-shaped tubes up to 350mm in diameter.

A: Yes, it features an intelligent loading system for high-speed, automatic tube feeding and sorting.

A: It integrates laser cutting, drilling, and tapping into one fully automated solution.

A: It’s ideal for automotive, furniture, fitness equipment, steel structures, and pipeline processing industries.

A: The TPSD uses a four-chuck full-stroke clamping design that supports rotation and precise tube positioning.