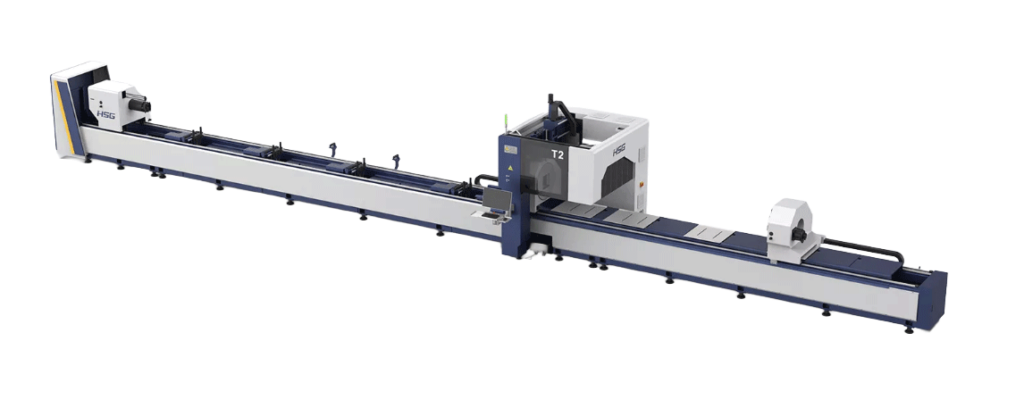

The T Series from HSG Laser offers high-speed tube cutting machines engineered for precision and efficiency, ideal for complex, automated tube processing in industrial applications.

Tube laser cutting machines like HSG Laser’s T Series have transformed metal fabrication by enabling high-speed, automated tube processing. They support industries such as construction, furniture, and automotive with improved accuracy and flexibility. These machines help streamline production and meet evolving market demands.

The T Series features full-automatic loading and unloading, auto centering, and intelligent clamping for fast and precise cutting. Compatible with round, square, rectangular, and special-shaped tubes, the T Series uses high-powered lasers and intelligent systems to boost efficiency, precision, and material utilization in industrial workflows.

Choosing the T Series ensures high-speed automation, reduced labor, and consistent quality. Ideal for scaling operations, it supports mass production needs while minimizing waste and maximizing performance.

Click the dropdowns below to view detailed specifications for the T Series.

Specification | Metric | Imperial |

Laser Power | 3kW – 6kW | 3000W – 6000W |

Tube Processing Range | T2 Round tube: 20mm – 240mm Square tube: 20mm x 20mm – 240mm x 240mm Diagonal≤330mm T3 Round tube: 20mm – 350mm Square tube: 20mm x 20mm – 350mm x 350mm Diagonal≤495mm | T2 Round tube: 0.79in – 9.45in Square tube: 0.79in x 0.79in – 9.45in x 9.45in Diagonal≤13in T3 Round tube: 0.79in – 13.78in Square tube: 0.79in x 0.79in – 13.78in x 13.78in Diagonal≤19.5in |

Range of Incoming Materials for Tube | 1000mm – 7000mm (T2) 1000mm – 9000mm (T3) | 39.37in – 275.59in (T2) 39.37in – 354.33in (T3) |

Positioning Precision of X/Y Axis | ±0.03mm/m (T2) ±0.05mm/m (T3) | ±0.00035 in/ft (T2) ±0.00059 in/ft (T3) |

Repetitive Positioning Precision of X/Y Axis | ±0.03mm | ±0.00118in |

Speed of Chuck | 100 RPM (T2) 80 RMP (T3) | |

Max Linkage Speed | 100 m/min (T2) 80 m/min(T3) | 328ft/min (T2) 262ft/min (T3) |

Max Linkage Acceleration |

0.8 G (T3) | |

Max Single Tube Weight | About 300kg (T2) About 600kg (T3) | About 661lb (T2) About 1323lb (T3) |

Bevel Option | Yes, all bevel cutting pipes should be above 50mm, thickness above3mm | |

Bevel Angle | ±45° | |

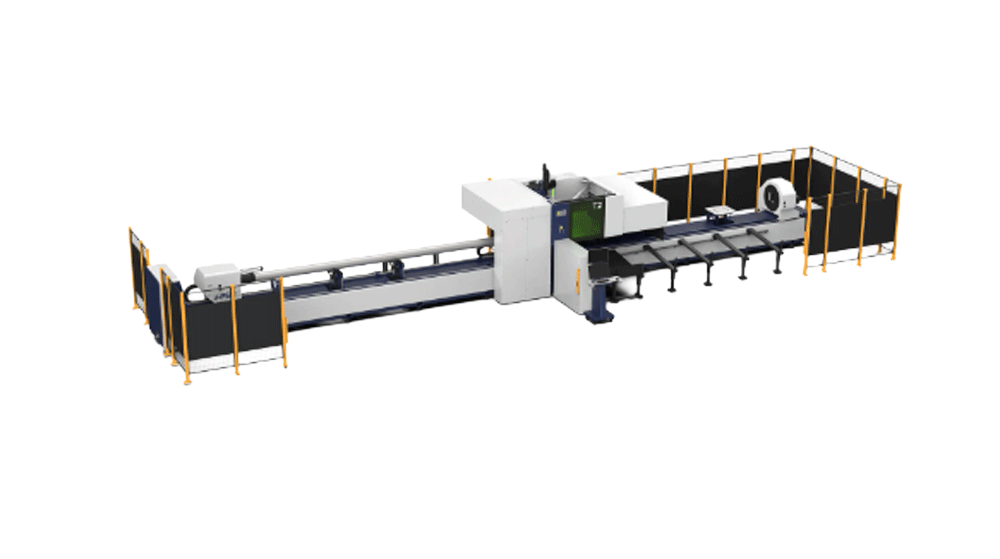

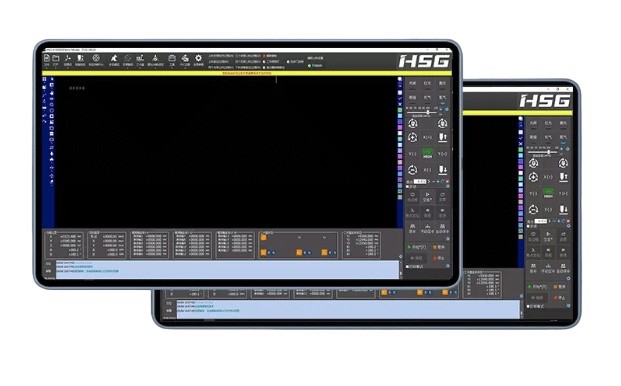

Core Attributes | Three-Chuck Tube Laser Cutter: Delivers precise control and strong clamping for long and complex tubes Independent Servo-Driven Support: Adaptive follow-up system ensures accuracy during high-speed cutting Smart Bus Control Platform: Offers seamless operation with intelligent automation features Fully Mobile Three-Chuck System: Flexible configuration allows for enhanced material handling and positioning | |

A: The T Series supports round, square, rectangular, L-shaped, U-shaped, and special-profile tubes for flexible applications.

A: It can process tubes up to 6 meters or 9 meters long, depending on configuration, ideal for industrial-scale projects.

A: Yes, it features fully automatic loading and unloading, which saves time, boosts safety, and reduces manual labor.

A: Commonly used in fitness equipment, furniture, automotive, and pipeline manufacturing due to its speed and precision.

A: The T Series supports various laser powers, typically from 1.5kW to 6kW, enabling both thin and thick tube cutting tasks.