These filtration systems protect worker health, reduce downtime from equipment contamination, and ensure regulatory compliance. Investing in proper air filtration boosts operational efficiency, safety, and air quality.

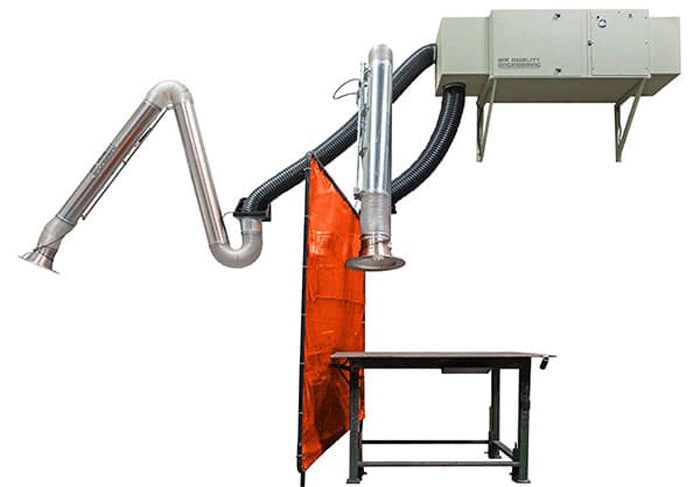

Extruding and Molding Air Filtration systems from Air Quality Engineering are expertly engineered to remove oil smoke, plastic fumes, and airborne particulates common in plastics manufacturing processes.

Air filtration for extruding and molding is critical to maintaining a safe, efficient, and compliant manufacturing environment. These systems are essential in plastic processing industries where fumes, vapors, and smoke are generated. Air Quality Engineering provides tailored solutions that improve air quality, reduce health risks, and meet OSHA and EPA standards.

Air Quality Engineering’s filtration systems feature advanced HEPA and electrostatic filtration technologies, customizable airflow capacities, and compact modular designs. Built to handle high-volume emissions from extrusion and molding, these units offer efficient contaminant capture, ease of maintenance, and compliance with strict industry air quality requirements.

These filtration systems protect worker health, reduce downtime from equipment contamination, and ensure regulatory compliance. Investing in proper air filtration boosts operational efficiency, safety, and air quality.

Click the dropdowns below to view detailed specifications for the Extruding and Molding Air Filtration.

| Feature | Specification |

|---|---|

| Dimensions (H x W x D) | 73″ x 31.13″ x 41.25″ |

| Weight | 368 lbs (installed), 440 lbs (shipping) |

| Cabinet Construction | 16-gauge galvanized welded steel with baked enamel finish |

| Airflow Capacity | Up to 2,700 CFM |

| Motor Options | 1 HP (110-120V, 1-phase), 2 HP (208-240V, 1-phase), 3 HP (208-240V/440-480V, 3-phase) |

| Blower | Forward-curved, belt-driven centrifugal blower |

| Prefilter | 30-35% efficient pleated filter, 24″ x 24″ x 4″ |

| Primary Filter | 24″ x 24″ x 22″ 8-pocket bag filter, 66 sq. ft. synthetic media |

| Filter Efficiency Options | 35%, 50%, 65%, 85%, 95% |

| Filter Access | Side-load track system with hinged access door |

| Sound Levels | 67 dBA at 9′, 66 dBA at 15′ |

| Additional Features | Dirty filter gauge, indicator light, heavy-duty swivel casters |

| Optional Equipment | Halogen light for source capture hood, activated carbon module, double arm configuration, motor upgrades |

| Feature | Specification |

|---|---|

| Airflow Capacity | Up to 5,000 CFM |

| Blower | 5 HP backward-inclined blower wheel |

| Filtration Stages | Two-stage filtration for extended filter life and low operating cost |

| Feature | Specification |

|---|---|

| Dimensions (H x W x D) | 21″ x 58″ x 98″ |

| Weight | 656 lbs (unit), Optional Arm: 73 lbs (13′ length) |

| Airflow Volume | 2,500 CFM total (1,250 CFM per arm) |

| Motor | 5 HP TEFC |

| Blower | Direct drive backward-inclined airfoil wheel, 13.5″ diameter |

| Filtration | Four high-efficiency cartridge filters, 12.75″ diameter x 30″, totaling 1,100 sq. ft., 99.8% efficient at 0.5 micron |

| Filter Cleaning System | Automatic reverse pulse with solid-state control timer |

| Power Requirements | 208-240V (13.4 amps max, 3-phase), 440-480V (6.6 amps max, 3-phase) |

| Cabinet Construction | 16-gauge welded steel with durable baked enamel paint |

| Optional Features | Externally supported 13′ arms with 360° rotation, double arm configuration (6″ or 8″ diameter), hood-mounted halogen light and controls, silencer, sprinkler weldment, various filter options including flame retardant and hydro-oleophobic coated |

| Feature | Specification |

|---|---|

| Airflow Capacity | M266O: 4,000 CFM; M366O: 6,000 CFM; M466O: 8,000 CFM |

| Cabinet Construction | 16-gauge steel with powder-coated chemical-resistant baked enamel finish |

| Filtration | Multi-stage pre-filter and primary filter options, customizable for specific contaminants; optional HEPA filtration and/or odor modules available |

| Installation | Designed for floor or ceiling mounting; scalable configurations with two, three, or four M66O systems based on airflow requirements |

| Applications | Suitable for coolant mist, grinding dust, process smoke, welding fumes, and other industrial pollutants |

| Feature | Specification |

|---|---|

| Dimensions (H x W x D) | 73″ x 31.13″ x 41.25″ |

| Weight | 368 lbs (installed), 440 lbs (shipping) |

| Cabinet Construction | 16-gauge galvanized welded steel with powder-coated finish |

| Mounting Configuration | Vertical design for limited floor space installations |

| Airflow Capacity | Up to 2,700 CFM |

| Motor Options | 1 HP, 2 HP, or 3 HP (available in 1- or 3-phase configurations) |

| Blower Type | Belt-driven, forward-curved centrifugal blower |

| Prefilter | 30-35% pleated filter (24″ x 24″ x 4″) |

| Primary Filter | 24″ x 24″ x 22″ 8-pocket bag filter (66 sq. ft. media) |

| Filter Efficiency Options | Available in 35%, 50%, 65%, 85%, 95% |

| Sound Level | Approx. 67 dBA at 9 feet |

| Filter Access | Side-load with hinged access door |

| Optional Features | Carbon odor modules, lighted hoods, remote controls, double-arm source capture |

A: They effectively capture plastic smoke, oil mist, fumes, and other airborne particulates from extrusion and molding operations.

A: Yes, Air Quality Engineering offers customizable units to fit unique space, airflow, and pollutant volume requirements.

A: Absolutely. All systems are designed to meet or exceed OSHA and EPA regulations for indoor air quality.

A: Filter maintenance depends on use, but many units use washable electrostatic filters and offer service indicators for easy maintenance tracking.

A: Yes, many models are designed to integrate seamlessly with existing ventilation or HVAC systems to enhance facility-wide air quality.