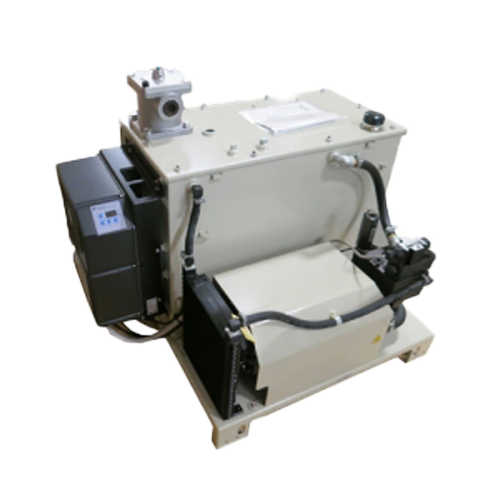

Core Pull SUT10D80 from Daikin offers advanced hydraulic solutions for precision plastic injection molding, ensuring optimal performance and reliability. Engineered for efficiency, this core pull system enhances productivity in industrial applications.

The Core Pull SUT10D80 by Daikin revolutionizes plastic injection molding with its state-of-the-art hydraulic system. Designed to meet the industry’s demand for precision and efficiency, this core pull unit optimizes the molding process. Its innovative design caters to a wide range of applications, offering unparalleled control, speed, and durability essential for modern manufacturing.

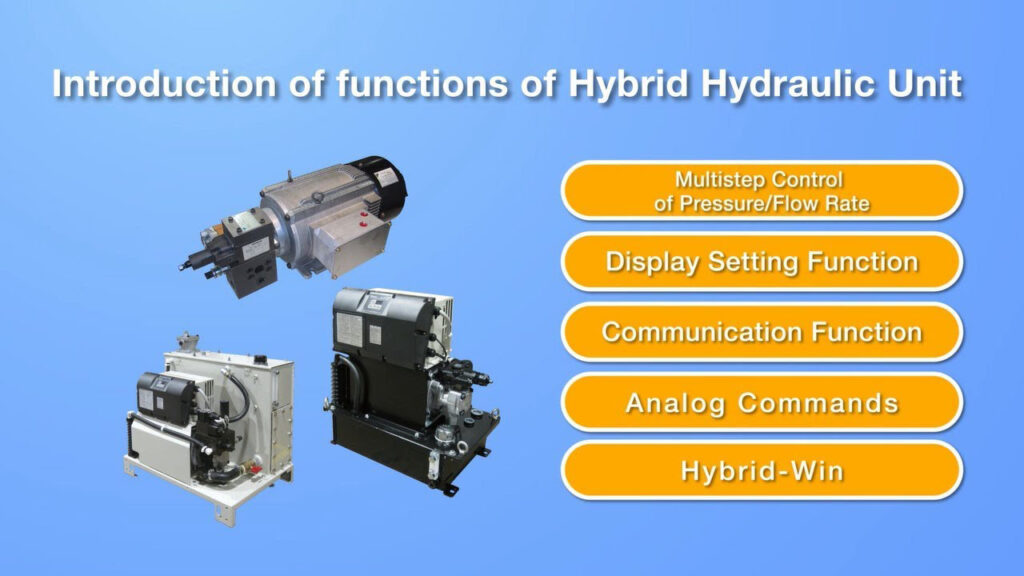

The Core Pull SUT10D80 boasts cutting-edge features, including precise hydraulic control for superior molding accuracy, compact design for easy integration, and energy-efficient operation. Its robust construction ensures reliability under heavy use, while customizable settings accommodate diverse molding requirements, making it a versatile choice for manufacturers.

Choosing the Core Pull SUT10D80 enhances production efficiency, minimizes downtime, and ensures consistent, high-quality results. Its advanced technology reduces energy consumption, lowering operational costs while delivering superior performance. This system is ideal for industries prioritizing precision and reliability.

Click the dropdowns below to view detailed specifications for the Core Pull SUT10D80.

| Core Pull SUT10D80 Specifications | |

|---|---|

| Flow Rate | 21 gallons per minute (GPM) |

| Maximum Pressure | Up to 2,500 PSI |

| Motor Power | 9 HP |

| Valve Size Options | D05 or D08 size valves |

| Reservoir Capacity | 25 gallons |

| System Type | High/Low system |

| Dimensions (W x L x H) | 25″ W x 36″ L x 46″ H |

| Energy Efficiency | Up to 63% energy savings compared to standard units |

| Noise Level | Quiet operation at 60 to 68 dBA |

| Cooling Requirements | No cooling water required |

| Integration | Compatible with multiple cores or auxiliary functions, such as valve gates |

| Control Features | Keypad for easy adjustment of pressure and flow |

A: It is designed for precision hydraulic control in plastic injection molding applications, ensuring accurate and efficient core pulling.

A: Yes, it offers adjustable settings to cater to diverse manufacturing requirements, enhancing flexibility.

A: Its energy-efficient design reduces power consumption while delivering precise control and reliable operation, optimizing production cycles.

A: Yes, its compact and versatile design ensures easy integration with most standard molding systems.

A: Routine checks and standard hydraulic system maintenance will ensure longevity and optimal performance.